Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

Efficient lubrication systems

are integral to the smooth operation of machinery across various industries. Among the key components of these systems,

the lube pump plays a crucial role in ensuring the delivery of lubricant

to critical engine and machine parts, thereby minimizing wear and tear and enhancing overall performance.

According to a report by MarketsandMarkets, the global lubricant market is projected to reach

$155 billion by 2024, with a significant portion driven by advancements in

lubrication technology, particularly in lube pump design and efficiency.

Efficient lubrication systems

are integral to the smooth operation of machinery across various industries. Among the key components of these systems,

the lube pump plays a crucial role in ensuring the delivery of lubricant

to critical engine and machine parts, thereby minimizing wear and tear and enhancing overall performance.

According to a report by MarketsandMarkets, the global lubricant market is projected to reach

$155 billion by 2024, with a significant portion driven by advancements in

lubrication technology, particularly in lube pump design and efficiency.

Research indicates that improper lubrication can lead to machinery failure, resulting in downtime costs

that can exceed thousands of dollars per hour.

The American Society of Lubrication Engineers emphasizes that adopting advanced lube pump technologies can

improve system reliability and operational efficiency. By understanding the mechanisms behind these pumps,

companies can optimize their lubrication systems, leading to enhanced productivity and reduced maintenance costs.

In this comprehensive guide, we will explore the top five factors influencing lube pump performance and provide

insights into best practices for maintaining effective lubrication systems.

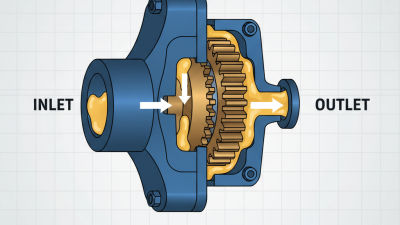

Key Components of Lube Pumps and Their Functions

Lube pumps play a critical role in ensuring the smooth operation of lubrication systems by delivering oil or grease to necessary components. Key components of lube pumps include the pump mechanism itself, motor, reservoir, and piping system. The pump mechanism is responsible for drawing in lubricant and forcing it through the system at a desired pressure. This ensures all moving parts receive adequate lubrication, reducing wear and tear, and enhancing the lifespan of machinery.

One crucial tip is to regularly check and maintain the pump's motor and reservoir to prevent any potential breakdowns. Ensuring that the lubricant used is compatible with the pump materials can significantly enhance efficiency and performance. Additionally, it's essential to monitor the piping system for any leaks or blockages.

Another important component is the filter, which helps keep the lubricant clean by removing contaminants. This not only improves performance but also protects sensitive machinery parts. Therefore, routine filter inspections and replacements are recommended to ensure optimal functioning of the lube pump system.

5 Essential Types of Lubrication Systems for Optimal Performance

Lubrication systems play a vital role in ensuring the smooth operation of machinery by minimizing friction between moving parts. Among the various types, the first essential system is the **manual lubrication system**, which relies on the operator to apply lubricant directly to the parts that need it. While this method is simple and cost-effective for small equipment, it may not be efficient for larger machines that require consistent and precise lubrication.

Next, the **grease lubrication system** uses grease as a lubricant, making it ideal for environments where oil could drip or leak. This system often employs a grease gun and is widely used in automotive applications and heavy machinery due to its ability to provide a long-lasting and protective lubrication layer. Another critical type is the **circulating oil lubrication system**, which pumps oil through a series of filters, coolers, and reservoirs to lubricate multiple components simultaneously. This method ensures a steady oil supply and is especially effective in high-speed and high-load applications.

Lastly, **sump lubrication systems** and **mist lubrication systems** further enhance operational efficiency. The sump system collects and recirculates oil, using gravity to feed lubricant to key areas. In contrast, mist systems disperse oil in a fine mist, providing lubrication without significant buildup, perfect for machining operations. Understanding these lubrication systems is essential for maximizing performance and prolonging equipment life.

7 Critical Factors Influencing Lube Pump Efficiency

When it comes to the efficiency of lubrication systems, understanding the critical factors influencing lube pump performance is essential. One of the foremost aspects is the

pump design itself.

Pumps that are specifically engineered for the application can optimize flow rates and minimize energy consumption. High-quality materials that resist wear and corrosion also play a crucial role in maintaining the longevity and effectiveness of the pump.

Another significant factor is the viscosity of the lubricant being used. Thicker oils require more power to pump, which can impact overall efficiency.

Maintaining the correct temperature is vital as it affects the lubricant's viscosity and, consequently, the pump's performance. Additionally, regular maintenance practices such as

filter changes, seal inspections, and system cleaning can prevent blockages and ensure a steady flow, thereby enhancing the lube pump's operational efficiency. By focusing on these critical factors, operators can significantly improve the

performance and reliability of their lubrication systems.

Top 4 Maintenance Tips for Prolonging the Life of Your Lube Pump

Maintaining lube pumps efficiently is vital for prolonging their lifespan and ensuring optimal performance in lubrication systems. Regular upkeep not only enhances functionality but also prevents unexpected breakdowns. Here are some essential maintenance tips to follow.

First, always check the pump's fluid levels and quality. Contaminated or low lubricant can lead to increased wear and tear, impacting the pump's operation. It’s advisable to replace the lubricant according to the manufacturer’s recommendations to keep your system clean and effective.

Secondly, inspect the seals and hoses regularly. Over time, these components can wear out or become damaged, leading to leaks that can compromise the pump's efficiency. Timely repairs or replacements help maintain seals and prevent any loss of fluid, ensuring smooth operation.

Lastly, monitor the pump's pressure settings. Keeping pressure out of the pump when it's not in use can significantly extend its service life. A well-adjusted pressure system reduces stress on the pump components, promoting longevity and reliability in your lubrication setup.

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems - Top 4 Maintenance Tips for Prolonging the Life of Your Lube Pump

| Maintenance Tips | Description | Frequency | Expected Outcome |

|---|---|---|---|

| Regular Lubricant Checks | Ensure the correct lubricant is used and check for contamination. | Monthly | Prevents damage due to improper lubrication. |

| Filter Maintenance | Clean or replace filters to ensure optimal flow and filtration. | Quarterly | Improves pump efficiency and longevity. |

| Seal Inspection | Check seals for wear and tear to prevent leaks. | Every 6 months | Reduces the risk of oil loss and contamination. |

| Pump Alignment | Ensure the pump and motor are aligned correctly. | Yearly | Minimizes wear on components and improves performance. |

6 Signs That Indicate Your Lube Pump Needs Immediate Attention

When it comes to maintaining lubrication systems, recognizing the warning signs of a malfunctioning lube pump is crucial. Just as drivers are cautioned about specific car noises that may indicate severe mechanical issues—potentially leading to hefty repair costs—lube pumps also exhibit signs that demand immediate attention. According to industry reports, around 30% of machinery failures are attributable to improper lubrication, underscoring the importance of a fully functional lube pump to avoid costly downtime.

There are several key indicators that your lube pump may be in distress. First, a sudden drop in pressure can suggest a blockage or a malfunctioning component, which may hinder optimal lubricant flow. Additionally, unusual noises emanating from the pump, such as grinding or whining, are typical signs of wear and tear. Experts suggest that routine maintenance can prevent these issues, yet nearly 25% of businesses report they neglect regular checks, risking both equipment failure and expensive repairs that could exceed £5,000. Maintaining vigilant oversight of your lubrication system is not just proactive; it's essential for operational efficiency and safety.

Related Posts

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

Understanding the Benefits of Screw Pumps in Modern Industrial Applications