Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

The efficient transfer of fluids is critical across various industries, from oil and gas to food processing, making the understanding of the "types of positive displacement pumps" essential for optimizing operational performance. According to a recent report by MarketsandMarkets, the global positive displacement pump market is expected to reach approximately $8 billion by 2025, driven by increasing demand for consistent flow rates and strict regulatory standards.

Positive displacement pumps, characterized by their ability to move fluid by trapping a fixed amount and displacing it through the system, come in various designs, each tailored to specific applications. Whether it’s gear pumps, diaphragm pumps, or screw pumps, each type offers unique advantages that can enhance process efficiency and reliability. As industries continue to evolve, exploring these different types will provide valuable insights for engineers and decision-makers seeking to maximize fluid transfer capabilities while ensuring compliance and sustainability.

Understanding Positive Displacement Pumps: Key Characteristics and Applications in Fluid Transfer

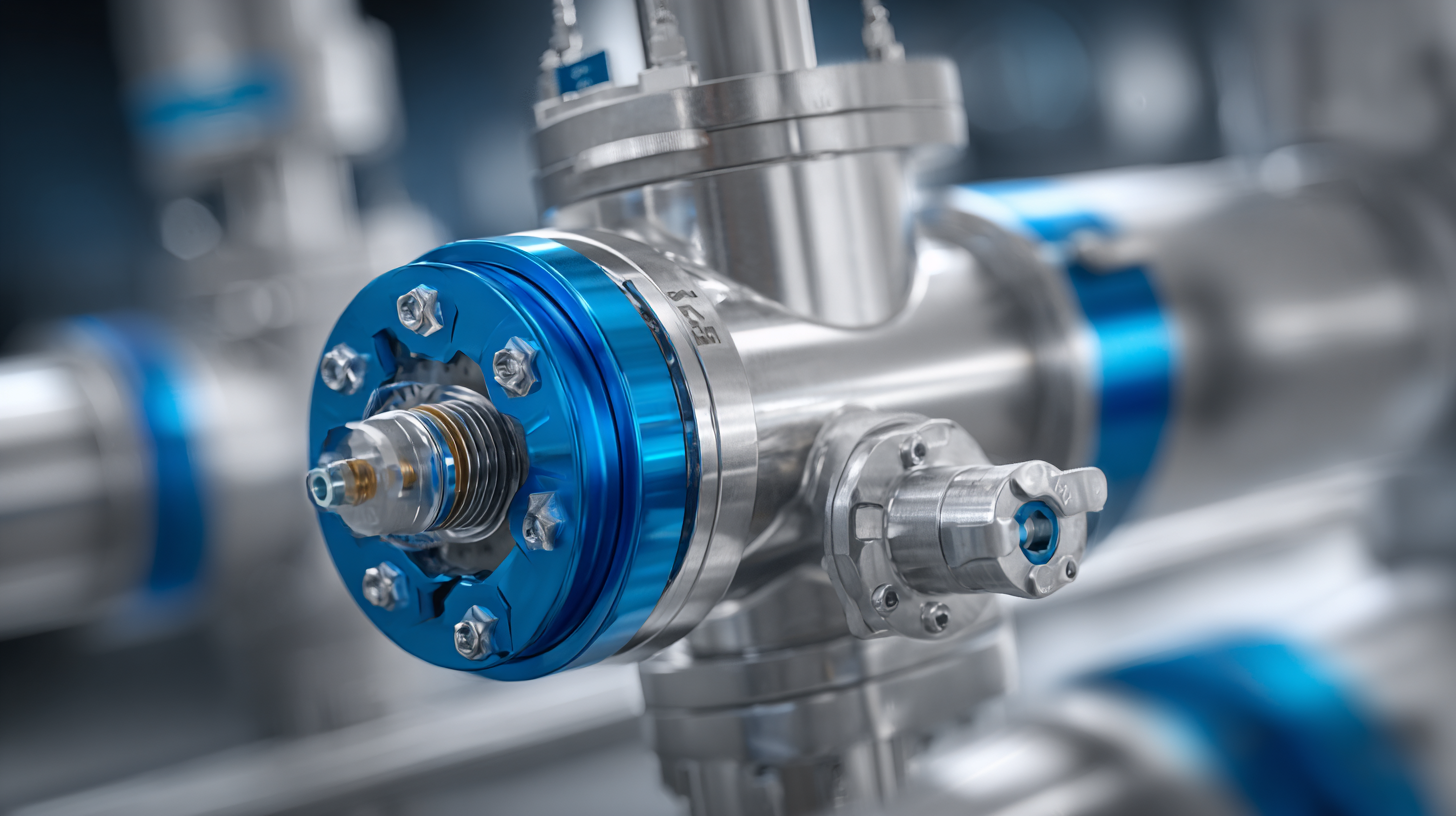

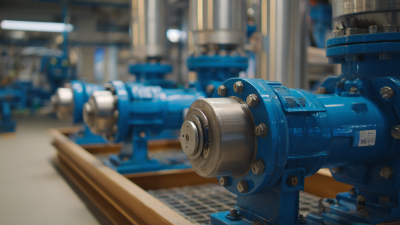

Positive displacement pumps are critical components in various industrial applications, designed to transfer fluids efficiently by moving a defined volume with each cycle. Unlike centrifugal pumps, which rely on a rotating impeller to create flow, positive displacement pumps operate on a distinct mechanism where fluid is trapped in a chamber and then forced out. This characteristic allows them to handle high viscosity fluids and achieve precise flow rates, making them ideal for industries such as oil and gas, pharmaceuticals, and food processing.

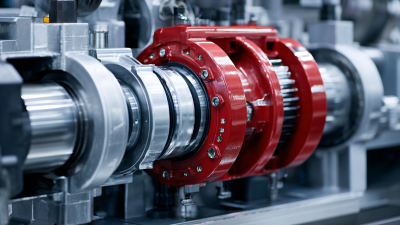

Understanding the key characteristics of positive displacement pumps is essential for optimizing fluid transfer processes. They can be categorized into two main types: rotary and reciprocating pumps. Rotary pumps, including gear and vane pumps, provide a continuous flow and are suitable for applications requiring a steady discharge. On the other hand, reciprocating pumps, such as diaphragm and piston pumps, are adept at handling varying flow rates and pressures. Their ability to maintain consistent performance regardless of changes in system pressure further emphasizes their versatility and reliability in fluid transfer operations.

Types of Positive Displacement Pumps and Their Applications

Comparative Analysis of Gear, Diaphragm, and Screw Pumps in Industrial Fluid Handling

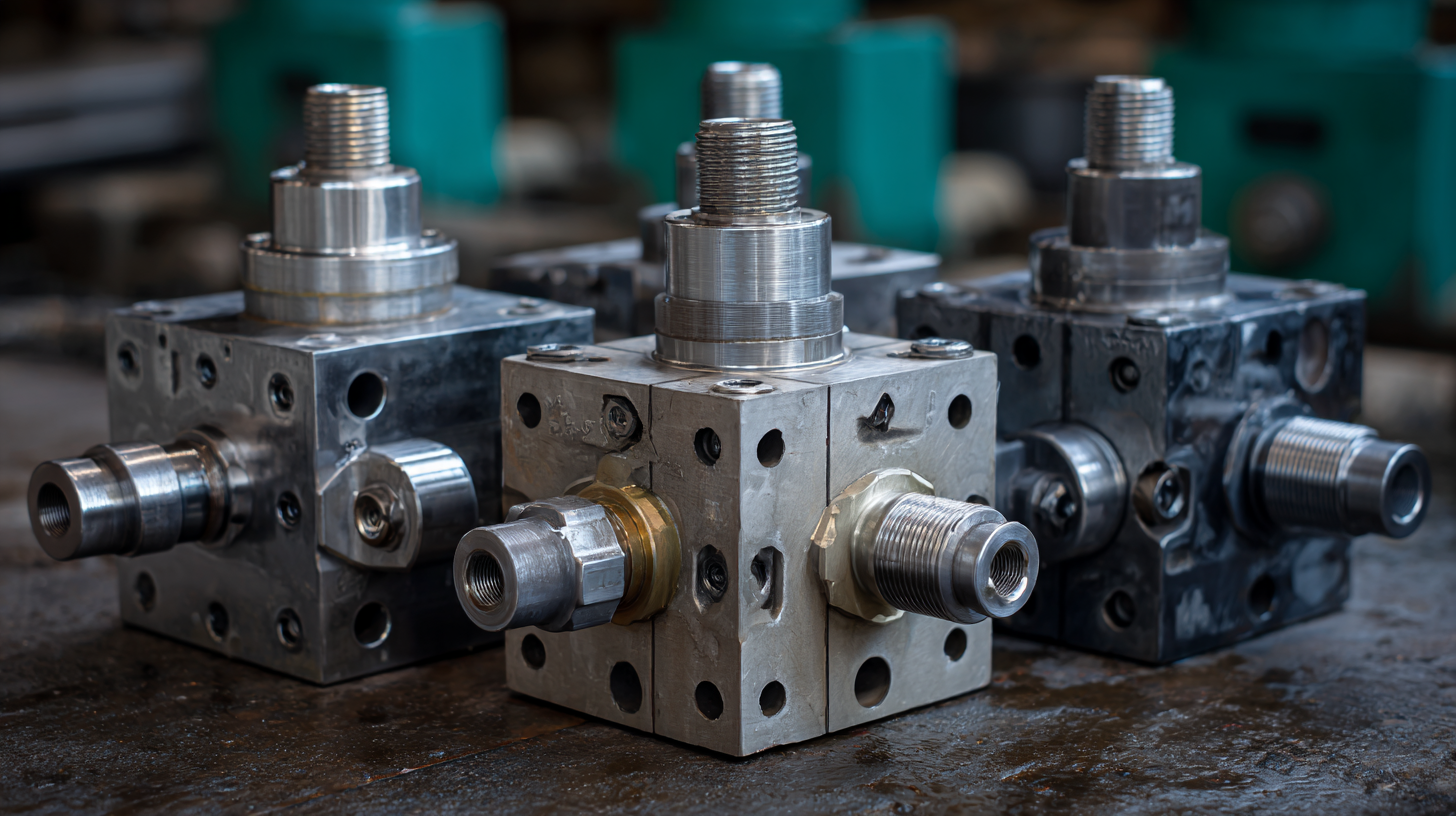

In industrial fluid handling, the choice of pump significantly affects efficiency, reliability, and cost-effectiveness. Gear pumps, known for their robust construction and ability to handle high-viscosity fluids, excel in applications requiring consistent flow rates. According to a recent report by Technavio, the global gear pump market is projected to grow by over 4% annually, driven by demand in sectors such as oil and gas, food processing, and chemical manufacturing. Their simple design and minimal maintenance needs make them a preferred choice for many industries.

Diaphragm pumps offer versatility and excellent suction capabilities, making them ideal for hazardous and abrasive fluids. The Fluid Power Journal highlights that diaphragm pumps can handle a wide range of fluid viscosities and provide a safe option for transferring toxic substances. As per industry data, diaphragm pumps have seen a market increase of approximately 6% annually, reflecting their growing popularity among manufacturers striving for safety and reliability in their operations.

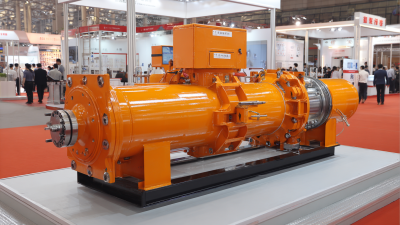

Screw pumps, on the other hand, are well-suited for applications requiring gentle pumping action, such as in the food and beverage industry. The Global Screw Pumps Market report states that the demand for these pumps is expected to rise significantly, especially in sectors where shear-sensitive fluids are handled. With their efficiency in maintaining product integrity and performance in various conditions, screw pumps are becoming an essential tool in modern fluid transfer systems across various industries.

Evaluating Efficiency: How Positive Displacement Pumps Optimize Flow Rates and Reduce Energy Consumption

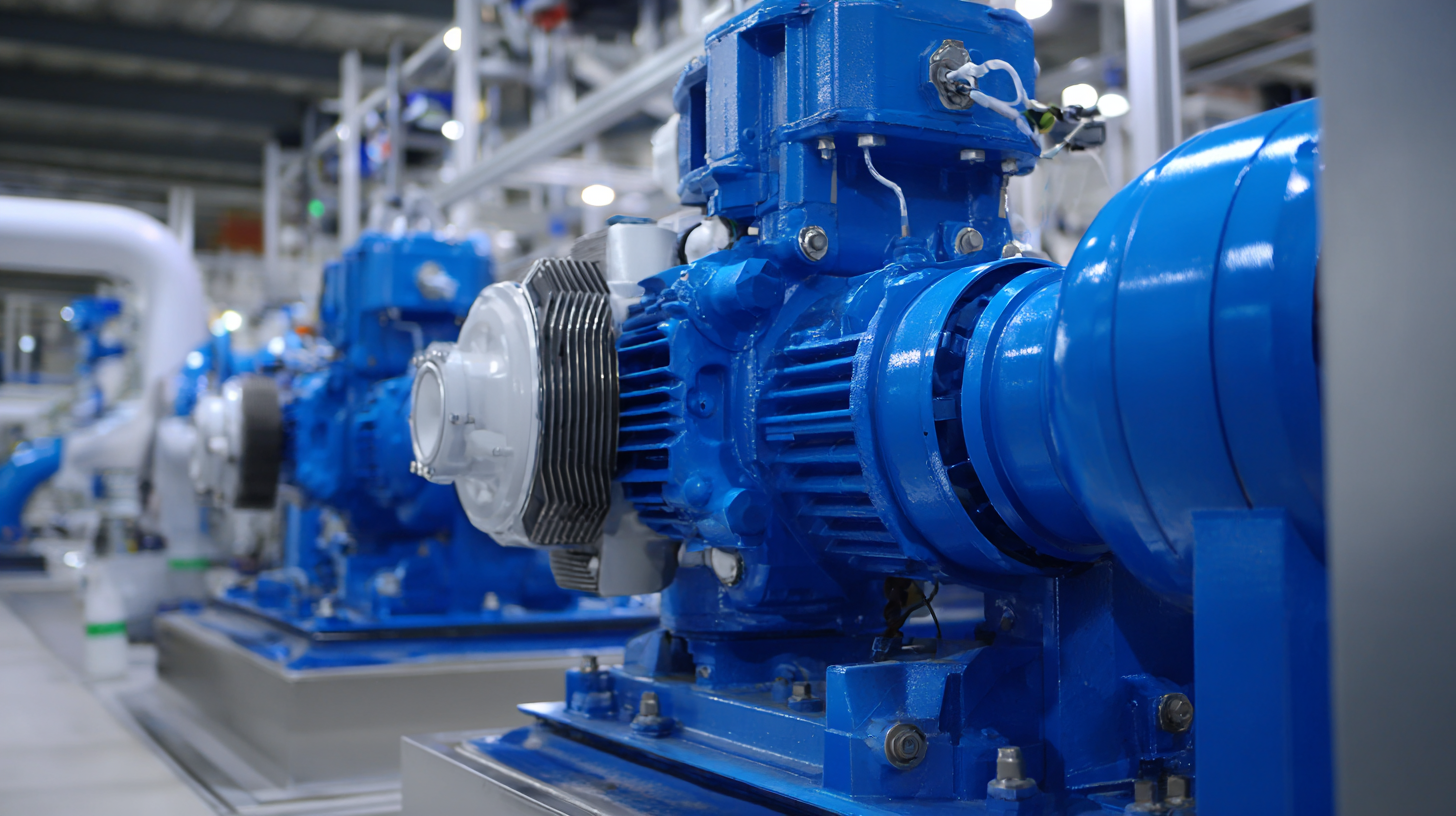

Positive displacement pumps are renowned for their ability to deliver consistent flow rates and optimize energy consumption. By trapping a fixed amount of fluid and forcing it into the discharge, these pumps maintain efficiency across a wide range of operational conditions. This capability is particularly beneficial in applications where precise flow control is crucial, such as in chemical processing or food and beverage production. The design of positive displacement pumps allows them to perform well with both highly viscous and low-viscosity fluids, making them versatile for different industries.

**Tips:** When selecting a positive displacement pump, consider the fluid's viscosity and the required flow rate. Additionally, ensure that the pump's materials are compatible with the fluid to prevent degradation and maintain efficiency. Regular maintenance can also enhance performance and longevity, reducing downtime and energy consumption.

Furthermore, the efficiency of positive displacement pumps can be significantly influenced by how they're integrated into a system. Attention to factors such as the layout of piping, the choice of motor, and the control systems can enhance overall performance. Utilizing variable speed drives can allow for better flow control and energy savings, ensuring that the pump only consumes the energy necessary to meet operational needs.

Maintenance Best Practices for Prolonging the Lifespan of Positive Displacement Pumps in Manufacturing

Maintenance is crucial for ensuring the efficient operation of positive displacement pumps in manufacturing settings. Regular inspections should be conducted to identify signs of wear or damage. This includes checking the seals, bearings, and internal components, as even minor issues can lead to significant operational inefficiencies. Additionally, keeping the pump clean and free from debris prevents unnecessary strain on the system, contributing to its longevity.

Lubrication is another key practice in maintaining positive displacement pumps. Operating these pumps under proper lubrication conditions reduces friction and wear on moving parts, which is essential for smooth operation. Manufacturers should follow the recommended lubrication schedule and choose the appropriate type of lubricant to match the pump’s specifications. Furthermore, implementing a routine maintenance schedule that includes regular testing and calibration can help in detecting performance declines before they escalate into major failures, ultimately enhancing the pump's lifespan.

Trends in Positive Displacement Pump Technologies: Innovations Driving Performance and Reliability in Fluid Transfer

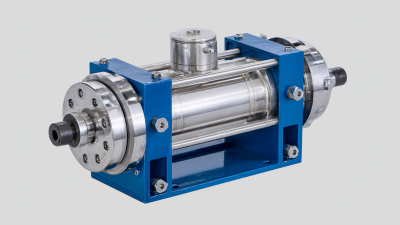

The landscape of positive displacement pump technologies has seen significant innovations aimed at enhancing performance and reliability in fluid transfer applications. According to a report by Grand View Research, the global positive displacement pump market is projected to reach USD 8.55 billion by 2025, growing at a CAGR of 5.9%. This growth is driven by the increasing demand for efficient fluid handling in industries such as oil and gas, water treatment, and food and beverage. New advancements, such as smart pump systems with integrated IoT capabilities, are facilitating real-time monitoring and predictive maintenance, which significantly reduces downtime and operational costs.

Furthermore, the design of positive displacement pumps is evolving, with manufacturers adopting new materials and technology to improve efficiency. A recent study published by Market Research Future identifies that the use of advanced composites and ceramics in pump construction not only enhances durability but also contributes to a 10-15% increase in energy efficiency. Innovations in sealing technologies, such as mechanical seals and diaphragm designs, have also enhanced reliability, mitigating issues related to leakage and wear. As these trends continue, industries can expect substantial improvements in the overall effectiveness of fluid transfer processes, ensuring they can meet the growing demands of a dynamic marketplace.

Related Posts

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs