Top Twin Screw Pump Manufacturers in 2026 What Are They?

In 2026, the landscape of twin screw pump manufacturers is evolving. Industries rely on these pumps for their efficiency and versatility. Many key players are redefining standards in technology and design.

As demands grow, manufacturers innovate to stay competitive. They enhance performance and durability, focusing on specific applications. Some brands lead in specialized features. Others prioritize cost-effectiveness and energy efficiency. This diversity presents choices for various sectors.

However, not all manufacturers maintain the same quality. Some struggle with reliability in their products. Customers must conduct thorough research to find trustworthy suppliers. Understanding market trends is crucial for making informed decisions. The future could hold surprises, but the right knowledge can guide users toward the best choices.

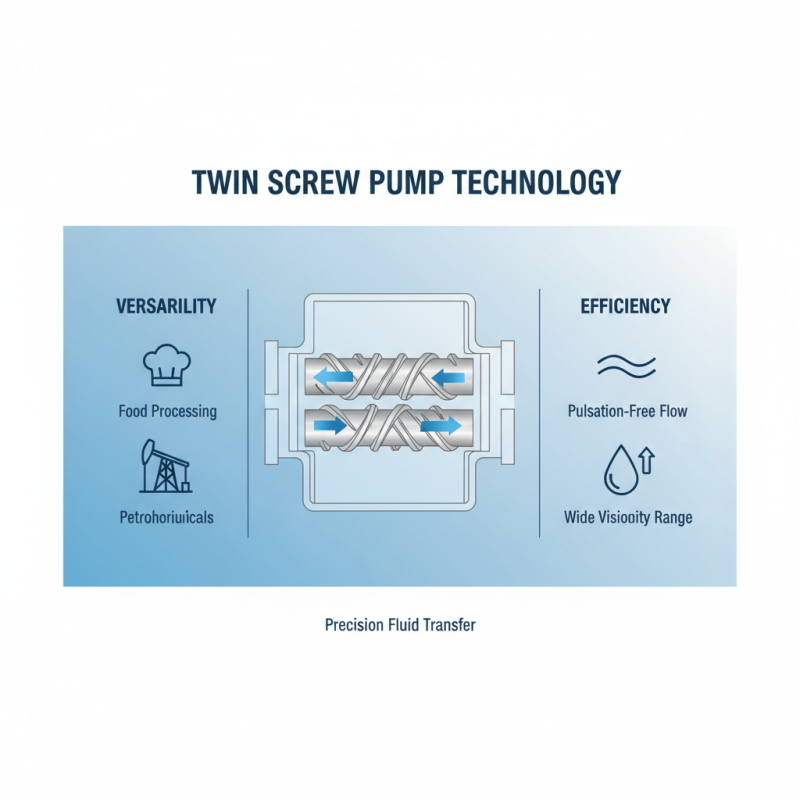

Overview of Twin Screw Pumps and Their Applications

Twin screw pumps have gained popularity in various industries due to their versatility and efficiency. These pumps work by utilizing two intermeshing screws to move fluids with precision. They can handle a wide range of viscosities, making them ideal for applications in food processing, petrochemicals, and pharmaceuticals. In these environments, consistent flow without pulsation is crucial.

Moreover, twin screw pumps are well-suited for handling abrasive and shear-sensitive materials. They can easily transport thick slurries, oils, and even sensitive biological fluids without damaging them. Their design allows for easy maintenance and cleaning, which is often essential in industries with strict hygiene standards. However, some users find the initial installation complex, and improper setup can lead to issues.

The efficiency of twin screw pumps also means that they can help reduce energy costs. However, achieving optimal performance often requires careful monitoring and adjustments. While these pumps have many advantages, there can be challenges in finding the right configuration for specific processes. Exploring the balance between performance and durability remains a point for further consideration.

Criteria for Evaluating Top Twin Screw Pump Manufacturers in 2026

When assessing the top twin screw pump manufacturers in 2026, several key criteria come into play. Quality is paramount. High-quality pumps enhance reliability. Customers look for longevity and efficiency in performance. Manufacturers must use durable materials and advanced technology.

Next, customer service plays a critical role. A responsive support team builds trust. Manufacturers should offer timely assistance and spare parts. Feedback from existing customers provides insight. Are they satisfied? Are their needs met?

Lastly, innovation matters. The industry evolves quickly. Companies need to adapt and introduce new features. Energy efficiency and smart technology integration are essential. However, not all innovations are successful. Some may overpromise and underdeliver. Continual improvement is necessary in this competitive market.

Leading Twin Screw Pump Manufacturers: Profiles and Key Products

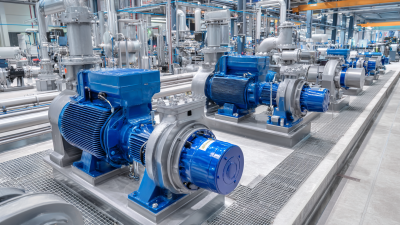

The twin screw pump market is evolving rapidly. By 2026, leading manufacturers are expected to show significant growth. Understanding the profiles of these key players helps in making informed decisions.

Many manufacturers focus on efficiency and reliability. Their pumps are widely used in various industries, including pharmaceuticals, food processing, and chemicals. A market report indicates that the demand for twin screw pumps is projected to grow at a CAGR of over 5% from 2021 to 2026. This growth highlights the importance of quality and technical innovation.

Tips: Always assess pump specifications. Functionality varies significantly between models. Prioritize energy efficiency in your selection process.

The evolution of technology also plays a crucial role. Several companies are investing in advanced materials and design improvements. However, some manufacturers still lag in adapting to new methodologies. This gap can impact performance and reliability in demanding applications.

Tips: Consider long-term maintenance costs. A pump's upfront price might be misleading. Quality can save you money over time.

Market Trends Influencing Twin Screw Pump Manufacturing in 2026

The twin screw pump market is evolving. By 2026, several trends will reshape manufacturing methodologies. Industry reports indicate a significant shift toward efficiency and sustainability. Manufacturers are expected to focus on reducing energy consumption by over 15%. This change aligns with global efforts for greener practices.

Technological advancements play a key role in this transformation. Data suggests that the implementation of smart technologies can improve operational performance by around 20%. However, companies face challenges. Not all enterprises can afford these upgrades. The gap between high-tech and traditional manufacturers may widen, affecting competition.

Customers now demand higher quality and reliability. Studies show that 70% of users will choose suppliers who ensure robust after-sales support. This puts pressure on manufacturers to innovate constantly. Yet, many still rely on outdated processes. It's a wake-up call for the industry. Addressing this issue will be crucial in the coming years.

Top Twin Screw Pump Manufacturers in 2026: Market Trends Influencing Twin Screw Pump Manufacturing in 2026

| Manufacturer Type | Annual Production Volume | Market Share (%) | Major Applications | Emerging Trends |

|---|---|---|---|---|

| Industrial Pumps | 15,000 units | 30% | Oil & Gas, Water Treatment | Automation Integration |

| Food Processing | 10,000 units | 25% | Dairy, Beverage Production | Sustainability Practices |

| Chemical Processing | 8,500 units | 20% | Pharmaceuticals, Petrochemicals | Advanced Materials |

| Marine Applications | 5,000 units | 15% | Ballast Systems, Cargo | Decarbonization Efforts |

| Mining Industry | 4,000 units | 10% | Slurry Transport, Hydro Processing | Efficiency Optimization |

Future Innovations in Twin Screw Pump Technology and Design

Twin screw pumps are evolving rapidly. Future innovations in their technology and design promise substantial improvements. One key development area is energy efficiency. New designs aim to reduce power consumption while maintaining high flow rates. This would benefit industries focused on cost savings and environmental responsibility.

Another exciting trend is the use of advanced materials. These materials can withstand higher pressures and corrosive environments. This development might extend the lifespan of pumps, offering companies more reliable equipment. However, switching to new materials can present challenges. Companies must ensure that their workforce is trained to handle these changes effectively.

Smart technology integration is on the rise too. Sensors and IoT can provide real-time data on pump performance. This innovation could lead to predictive maintenance, reducing downtime significantly. Yet, integrating these technologies requires significant investment. Not all companies may be ready or able to make this leap. Adapting to these changes may require time and careful planning.

Related Posts

-

Top Twin Screw Pump Manufacturers You Should Know About in 2023

-

How to Choose the Right Type of Industrial Pump for Your Application

-

Why Choose a Screw Vacuum Pump for Your Industrial Applications

-

2026 Best Oil Lubrication Pump for Enhanced Machinery Performance?

-

Top Lube Pump Types for Efficient Fluid Transfer Solutions?

-

Top Benefits of Positive Displacement Water Pumps and Their Uses