Top 10 Crude Oil Pumps for Efficient Energy Production?

In the energy sector, crude oil pumps play a crucial role in efficient energy production. According to a recent report by Global Energy Insights, the oil and gas sector relies heavily on these pumps. They are vital for extracting crude oil and ensuring a steady flow to refineries. Industry expert Dr. William J. Morrison states, "The performance of crude oil pumps can dictate the efficiency of production processes."

The demand for advanced pumping solutions is ever-growing. Experts suggest that better technology can significantly reduce production costs. However, not all pumps are created equal. Some may fail to perform under specific conditions, leading to inefficiencies. Maintenance remains a crucial factor in pump longevity. Investing in high-quality crude oil pumps can yield better returns in the long run.

As companies strive for sustainability, choosing the right pumps becomes critical. There will always be room for improvements in pump technology. Finding the optimal solution can be challenging. Nonetheless, the focus on efficient energy production through crude oil pumps is evident. As the industry evolves, so will the technology behind these essential tools.

Overview of Crude Oil Pumps and Their Importance in Energy Production

Crude oil pumps play a crucial role in energy production, facilitating the extraction and transportation of oil efficiently. These pumps are essential in maintaining the flow of crude oil from reservoirs to refineries. According to the International Energy Agency (IEA), global oil production is expected to reach 100 million barrels per day by 2025. As demand rises, having reliable and efficient pumps becomes increasingly important.

Efficiency in pumping systems can significantly affect production costs. Studies show that energy consumption in pumping can account for up to 25% of operational costs in oil extraction. Investing in high-efficiency pumps may lower these expenses. However, not all pumps will meet these efficiency standards. Operators often face challenges in selecting the right equipment for varying conditions.

Tips: Regular maintenance is vital for maximizing pump performance. Scheduled inspections can prevent costly breakdowns. Additionally, consider using advanced monitoring systems. These systems can provide real-time data on pump performance, allowing for timely adjustments.

In the pursuit of efficiency, it’s important to recognize the environmental impact of crude oil extraction. Some methods, while effective, can be detrimental to ecosystems. Exploring alternative energy sources should remain a focus for the industry. Balancing economic demand with environmental responsibility is crucial for sustainable energy production.

Top 10 Crude Oil Pumps for Efficient Energy Production

| Rank | Pump Type | Flow Rate (m³/h) | Pressure (bar) | Efficiency (%) |

|---|---|---|---|---|

| 1 | Centrifugal Pump | 100 | 10 | 85 |

| 2 | Positive Displacement Pump | 70 | 20 | 90 |

| 3 | Gear Pump | 60 | 15 | 82 |

| 4 | Diaphragm Pump | 50 | 12 | 88 |

| 5 | Submersible Pump | 80 | 18 | 83 |

| 6 | Rotary Vane Pump | 40 | 8 | 85 |

| 7 | Screw Pump | 90 | 14 | 89 |

| 8 | Peristaltic Pump | 35 | 6 | 81 |

| 9 | Progressive Cavity Pump | 45 | 9 | 84 |

| 10 | Vacuum Pump | 30 | 5 | 80 |

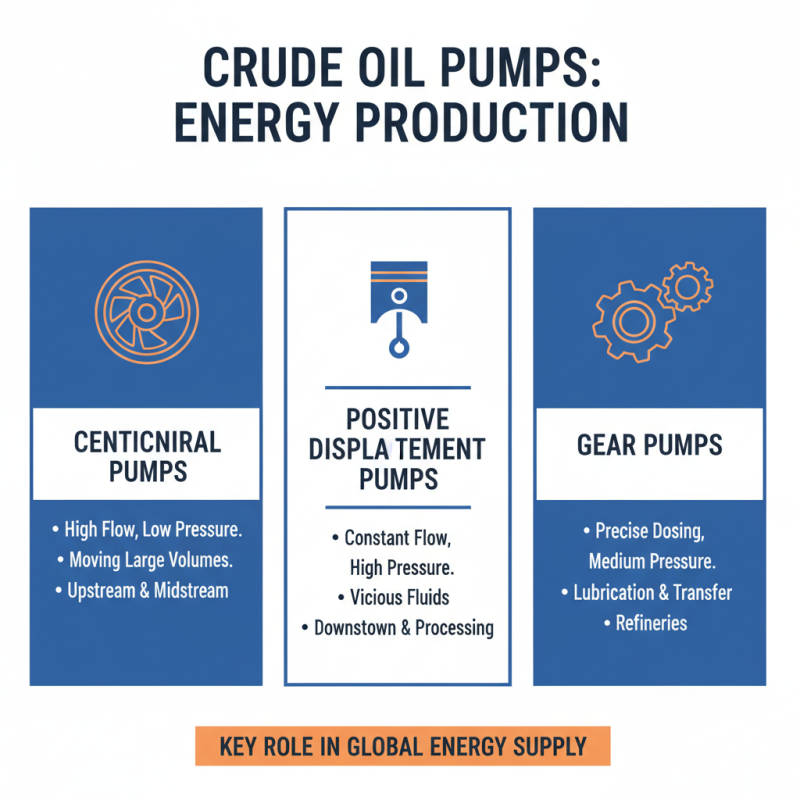

Types of Crude Oil Pumps Used in the Industry and Their Applications

Crude oil pumps play a crucial role in energy production. Different types of pumps are used based on the specific requirements of the industry. The most common types include centrifugal pumps, positive displacement pumps, and gear pumps. Each type has unique benefits and applications.

Centrifugal pumps are ideal for large volumes of liquid. They're efficient and simple to operate. However, they may struggle with viscous fluids. Positive displacement pumps excel in handling thick or viscous crude oil. They ensure a steady flow but can be more complex to maintain. Gear pumps, on the other hand, offer compact designs and reliability.

Tips: Always consider the viscosity of crude oil when selecting a pump. Higher viscosity may require a specialized pump type. Regular maintenance is essential to ensure efficiency. Neglecting it can lead to performance issues and costly repairs. Monitor pump performance continuously for optimal results. Reactive maintenance often comes too late.

Key Features to Consider When Selecting Crude Oil Pumps for Efficiency

Selecting the right crude oil pump is crucial for efficient energy production. Understanding key features can enhance overall performance. Look for pumps with high efficiency ratings. A pump's design and materials directly impact its durability. Corrosion resistance is vital since crude oil can be harsh.

Consider the pump's flow rate. It must match your production needs. An oversized pump can lead to energy wastage. On the other hand, undersized pumps can cause bottlenecks.

Tips: Always evaluate the maintenance requirements. Pumps that are easy to service can save time and money. Regular maintenance can prevent costly failures. Also, assess the noise levels. Quiet operation can be beneficial in reducing environmental impact. Balance efficiency with practicality for the best results.

Top 10 Crude Oil Pumps: Performance Comparisons and Specifications

When selecting a crude oil pump, performance and specifications play a crucial role. There are various types of pumps available, each suited to different operational needs. Some pumps excel at high pressure, while others focus on flow rate. Understanding these specifications can help operators make informed decisions.

For instance, a pump’s efficiency often relates to its design and materials. Pumps made from corrosion-resistant materials tend to last longer. Additionally, maintenance schedules are essential. Regularly maintaining pumps can prevent unexpected failures and enhance efficiency.

While comparing performance metrics, it’s vital to consider energy consumption. Some pumps may use less energy but compromise on output. Finding that balance can be challenging. Operators should also reflect on their unique situations. Each oil field may present different challenges. Choosing the right pump is not just about specifications; it's about the real-world application and adaptability to ever-changing environments.

Top 10 Crude Oil Pumps: Performance Comparisons

This chart illustrates the efficiency of the top 10 crude oil pumps, measured in liters per minute (L/min). Each pump's performance can significantly impact energy production efficiency.

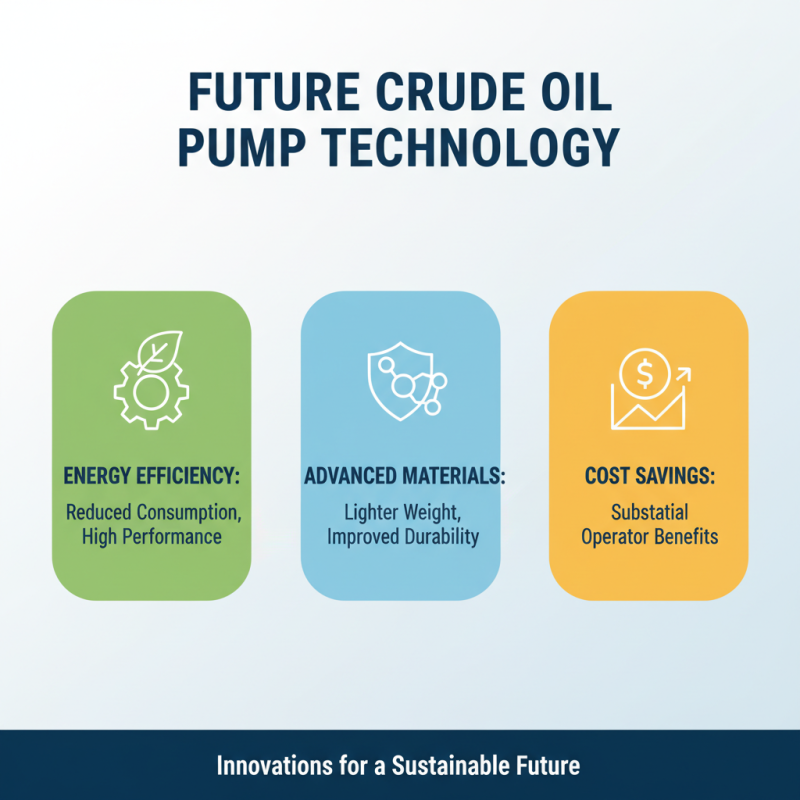

Future Trends in Crude Oil Pump Technology and Energy Efficiency

The future of crude oil pump technology is focusing on energy efficiency. New designs aim to reduce energy consumption while maintaining high performance. Advanced materials are helping to lower weight and improve durability. These innovations can lead to substantial cost savings for operators.

Moreover, automation is becoming essential. Smart pumps equipped with sensors can monitor performance in real-time. They can optimize flow rates and detect issues early. This reduces downtime and enhances reliability. However, there are gaps in existing technology that need addressing. Some operators may resist changes due to initial costs or complexity.

Sustainability is also a pressing concern. As the world shifts towards greener energy sources, crude oil pumps may face scrutiny. There's a need for dialogue within the industry about adapting. What works efficiently today might not be viable tomorrow. Balancing current practices with future demands will require careful consideration.

Related Posts

-

What is a Crude Oil Pump and How Does It Work?

-

Top 10 Essential Pumps for Oil: Your Ultimate Buying Guide

-

Why You Should Choose Air Oil Pumps for Your Industrial Needs Today

-

Top 10 Pumps for Oil to Maximize Efficiency and Performance

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency