What is a Screw Vacuum Pump and How Does It Work?

A screw vacuum pump is a vital tool in various industrial applications. This equipment efficiently creates a vacuum by using two rotating screws. Experts like Dr. Emily Hart, a leading authority in vacuum technology, emphasize its importance: "Screw vacuum pumps optimize performance and reduce energy consumption."

In today's fast-paced manufacturing environment, the screw vacuum pump plays a crucial role. It offers reliable performance for processes like packaging and material handling. However, the technology does have its challenges. Companies must ensure proper maintenance to avoid performance issues. Failing to do so can lead to unexpected downtime.

Understanding the mechanics of a screw vacuum pump is essential for maximizing its effectiveness. Each component must work in harmony. Any deviations from optimal performance require reflection and adjustments. As the industry evolves, embracing these innovations is vital for future success.

Understanding the Basics of Screw Vacuum Pumps: An Overview

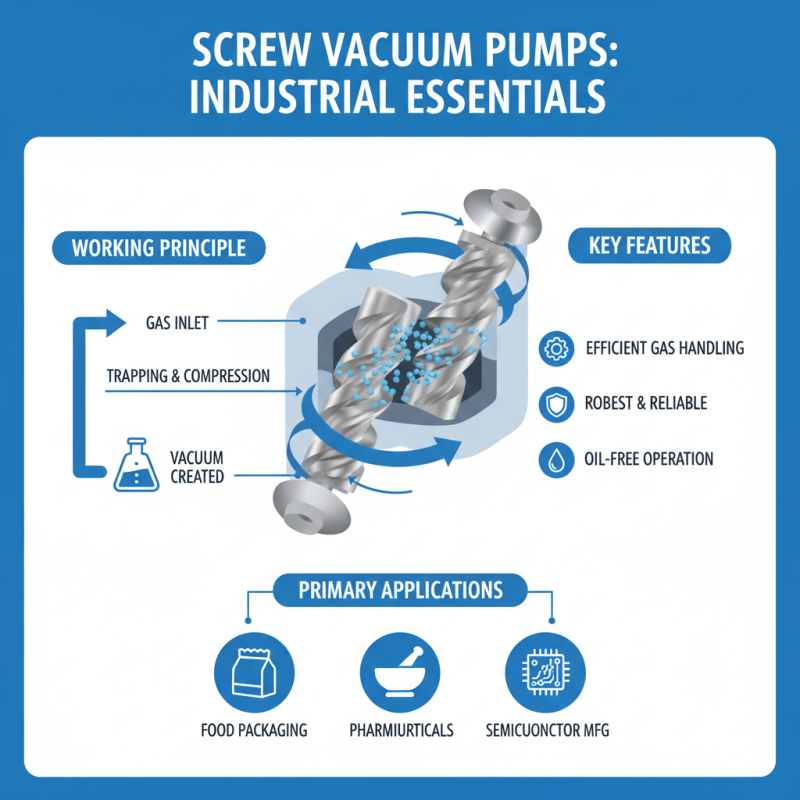

Screw vacuum pumps are essential tools in various industrial applications. These pumps operate on a simple principle: they utilize two intermeshing screws to trap and compress gas, creating a vacuum. This mechanism allows for efficient gas handling, making screw vacuum pumps popular in sectors like food packaging, pharmaceuticals, and semiconductor manufacturing.

According to a recent industry report by MarketsandMarkets, the global vacuum pump market is expected to reach USD 4.7 billion by 2025. This growth reflects the rising demand for efficient vacuum solutions. Screw vacuum pumps, known for their reliability and low maintenance, hold a significant share of this market. Their ability to maintain a continuous vacuum level is crucial in processes where contamination must be avoided.

Despite their advantages, screw vacuum pumps are not without challenges. Users often face issues with noise and vibrations, which can affect overall system performance. Additionally, the initial investment can be substantial, leading some companies to hesitate in their adoption. The ongoing evolution of technology may address these concerns, but users must remain adaptable and open to innovation.

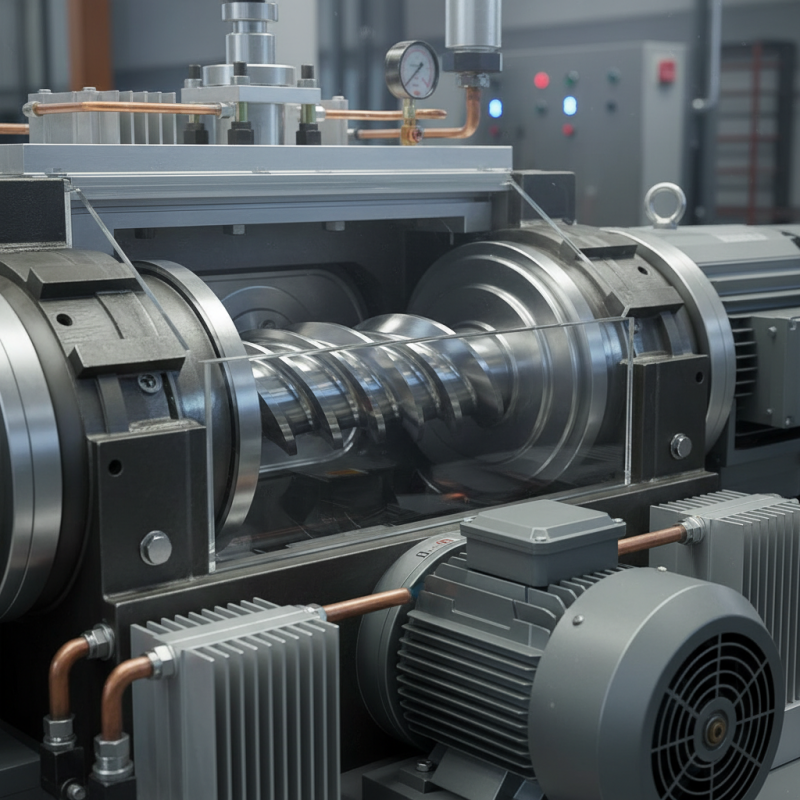

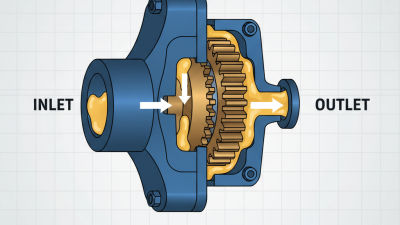

Key Components of a Screw Vacuum Pump and Their Functions

A screw vacuum pump operates based on two interlocking screws. These screws rotate in opposite directions. This motion creates a vacuum by drawing in air and expelling it. The design minimizes internal leakage, maximizing efficiency. Reports indicate that the efficiency of screw vacuum pumps can reach up to 90% under optimal conditions.

Key components include the rotor and housing. The rotor consists of twin screws, which are precisely machined. This precision is crucial for effective air compression and reduced wear. The housing contains the lubrication system, which helps maintain smooth operation. Moreover, temperature control is essential. Overheating can reduce efficiency and damage components. Industry studies highlight that consistent temperature monitoring can prolong pump lifespan by 30%.

Another important component is the inlet and outlet system. It requires proper sizing to avoid flow restrictions. Inadequate sizing may lead to increased energy consumption. Experts note that an ideal inlet size can reduce operational costs by up to 20%. Regular maintenance is necessary to ensure all these components function optimally. Neglecting maintenance can result in performance drops and costly repairs. Understanding these key components helps in making informed decisions in industrial applications.

The Operating Principle of Screw Vacuum Pumps Explained

Screw vacuum pumps are essential in various industries, from food packaging to pharmaceutical production. Their design promotes energy efficiency, producing a consistent vacuum without emitting oils or contaminants. This feature is beneficial in processes where purity is crucial. Reports indicate that the global vacuum pump market is expected to grow significantly, reaching a value of over $4 billion by 2026. This surge highlights the demand for reliable vacuum solutions.

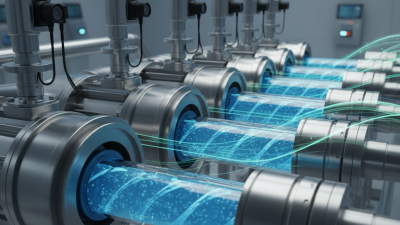

The operating principle of screw vacuum pumps relies on the rotation of two interlocking screws. As these screws turn, they trap air and compress it. The design minimizes the risk of wear due to the absence of contact between screws. This contactless mechanism often enhances the lifespan of the pump. However, if not maintained properly, even the best-designed pumps can experience issues like overheating or loss of efficiency. Operators must regularly examine seals and lubrication.

Moreover, parameters like the pump's speed and operating pressure greatly influence performance. Operating outside of optimal ranges can lead to pressure deficiencies and reduced output. Data suggests that proper system integration can improve efficacy by up to 30%. In some cases, training personnel on these nuances can enhance operational reliability. Industrial vacuum solutions require precision. Every detail counts; minor oversights can lead to significant inefficiencies.

Screw Vacuum Pump Performance Data

Performance Metrics: Efficiency and Pumping Speed of Screw Vacuum Pumps

Screw vacuum pumps are known for their efficiency and reliability. Performance metrics are crucial in evaluating these pumps. Two key metrics are efficiency and pumping speed. Efficiency indicates how much energy is converted into useful work. Pumping speed, measured in cubic meters per hour, shows how quickly a pump can remove gas from a chamber.

In various industry reports, the efficiency of screw vacuum pumps often ranges from 60% to 90%. These numbers vary based on design and operating conditions. High-efficiency models can significantly reduce operational costs over time. Also, pumping speeds can reach between 50 to 500 m³/h. These parameters reveal their suitability for applications like food packaging or semiconductor manufacturing.

However, not every application benefits equally. The actual performance may differ due to contamination or varying gas compositions. These factors can lower efficiency, creating challenges that require troubleshooting. Users often find it hard to maintain consistent performance across different environments. Regular performance assessments are needed for optimal operation. In some cases, users may have to reconsider their choice of pump based on performance metrics.

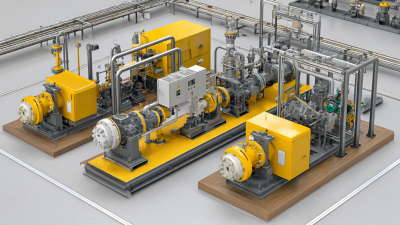

Applications of Screw Vacuum Pumps in Various Industries

Screw vacuum pumps are essential in various industries. They efficiently remove air and gases from sealed environments. These pumps create a vacuum essential for many applications. Their use is widespread in food processing, pharmaceuticals, and semiconductor manufacturing.

In food processing, screw vacuum pumps help in packaging. They keep products fresh by removing air from the packaging. This extends the shelf life of food items. In the pharmaceutical industry, these pumps enable precise control over processes. They ensure that products are created in a contamination-free environment.

Another significant application is in the semiconductor industry. Here, screw vacuum pumps assist in creating the ideal conditions for manufacturing microchips. They maintain a clean and controlled atmosphere. This is critical for high-quality production. However, users sometimes report issues with maintenance and efficiency. Users may overlook these aspects, leading to potential operational challenges.

Related Posts

-

Why Choose a Screw Vacuum Pump for Your Industrial Applications

-

10 Best Screw Pumps for Efficient Fluids Management in 2026?

-

What is a High Pressure Positive Displacement Pump and How It Works in Industrial Applications

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Top 10 Crude Oil Pumps for Efficient Energy Production?

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry