Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

The evolution of lube oil systems is poised to dramatically enhance engine performance and efficiency in the coming years. Recent studies indicate that optimizing lube oil viscosity and formulation can lead to a reduction in friction losses by up to 10%, resulting in significant fuel savings and lower emissions.

According to Market Research Future, the global lube oil market is anticipated to grow at a CAGR of 3.5% from 2021 to 2026, which underscores the increasing focus on advanced lubrication technologies. Innovations such as synthetic oil blends and intelligent lube oil monitoring systems are reshaping how engines operate, providing precise feedback for maintaining optimal lubrication under varying conditions.

As industry standards evolve and manufacturers seek sustainable practices, the lube oil system will play a critical role in achieving not only enhanced engine longevity but also contributing to greener automotive solutions.

The evolution of lube oil systems is poised to dramatically enhance engine performance and efficiency in the coming years. Recent studies indicate that optimizing lube oil viscosity and formulation can lead to a reduction in friction losses by up to 10%, resulting in significant fuel savings and lower emissions.

According to Market Research Future, the global lube oil market is anticipated to grow at a CAGR of 3.5% from 2021 to 2026, which underscores the increasing focus on advanced lubrication technologies. Innovations such as synthetic oil blends and intelligent lube oil monitoring systems are reshaping how engines operate, providing precise feedback for maintaining optimal lubrication under varying conditions.

As industry standards evolve and manufacturers seek sustainable practices, the lube oil system will play a critical role in achieving not only enhanced engine longevity but also contributing to greener automotive solutions.

Exploring Advanced Technologies in Lube Oil Systems for Enhanced Engine Performance

The evolution of lube oil systems is critical to enhancing engine performance and efficiency. Recent studies indicate that advanced lubrication technologies can reduce engine wear by up to 50%, leading to prolonged engine life and improved operational reliability. Innovations such as synthetic oils and advanced additives are revolutionizing the industry, offering superior thermal stability and oxidation resistance compared to conventional oils. According to a report by the American Society of Mechanical Engineers (ASME), adopting high-performance lubricants could yield fuel economy improvements of approximately 2-5%.

Furthermore, the integration of smart technologies, such as real-time monitoring systems, is transforming how lube oil systems operate. These technologies enable precise tracking of oil condition and performance metrics, facilitating predictive maintenance and minimizing unintended failures. A recent market analysis by Grand View Research highlights that the global smart lubrication market is projected to grow at a compound annual growth rate (CAGR) of 7% from 2022 to 2030. These advancements signify a paradigm shift in engine care, emphasizing the critical nature of lubrication in maximizing efficiency and performance for modern engines.

Key Benefits of Smart Lube Oil Management Systems for Efficiency

The advancement of Smart Lube Oil Management Systems marks a significant transformation in engine performance and efficiency. By leveraging Internet of Things (IoT) technologies, these systems enable real-time monitoring of oil quality and engine conditions. This proactive approach allows for predictive maintenance, ensuring that potential issues are identified and addressed before they result in costly breakdowns. The integration of smart sensors and analytics provides insights that help in maintaining optimal lubrication, enhancing engine longevity, and improving overall efficiency.

In addition to predictive maintenance, Smart Lube Oil Management Systems contribute to environmental sustainability. By optimizing oil usage and reducing wastage, these systems play a vital role in minimizing the ecological footprint of machinery. Furthermore, as industries increasingly focus on digital transformation, the ability to analyze and interpret data on lube oil performance can lead to smarter operational decisions, significantly boosting productivity. As we move towards a future where efficiency is paramount, embracing intelligent lubrication management will be key to achieving exceptional engine performance while aligning with sustainable practices.

Innovative Lubricants: How They Transform Engine Longevity and Functionality

Innovative lubricants play a crucial role in transforming engine longevity and functionality. As engines become more advanced, traditional lubricants are often unable to meet the rigorous demands of modern performance standards. Cutting-edge formulations, incorporating synthetic materials and advanced additives, have emerged to enhance the protective qualities of engine oils. These innovative lubricants minimize wear and tear, reduce friction, and improve heat dissipation, ultimately extending the life of vital engine components.

Moreover, the impact of these new lubricants extends beyond mere protection. They facilitate improved fuel efficiency by ensuring that engines run smoothly and efficiently under various operating conditions. Enhanced lubrication reduces the energy lost to friction, allowing engines to perform at optimal levels with less fuel consumption. As manufacturers continue to innovate in the field of lubricant technology, the future of engine performance looks brighter, with significant implications for both sustainability and operational costs in the automotive industry.

Real-Time Monitoring: The Role of IoT in Optimizing Lube Oil Performance

The integration of the Internet of Things (IoT) in lube oil systems is transforming engine performance and operational efficiency. As reported by the International Energy Agency (IEA), the adoption of IoT technology in the automotive sector can lead to a 10-15% improvement in fuel efficiency and performance optimization. Real-time monitoring of lube oil conditions, such as viscosity, temperature, and contamination levels, enables predictive maintenance, reducing downtime and maintenance costs. For instance, routine oil changes may be unnecessary when oil condition is continuously assessed, potentially saving operators up to 30% on maintenance expenditures, according to a report by McKinsey & Company.

Moreover, IoT sensors can communicate critical data to fleet managers or operators instantaneously. A study by the Society of Automotive Engineers (SAE) highlights that such connectivity results in a 25% reduction in failure rates of engine components, as timely interventions can be made based on the data collected. By enhancing lube oil management through IoT, companies can not only prolong the lifespan of their engines but also comply with increasingly stringent environmental regulations by minimizing lubricant waste and emissions. The future of engine performance lies in leveraging these innovative technologies to achieve both efficiency and sustainability.

Sustainability in Lube Oil Systems: Driving Efficiency and Environmental Impact

Sustainability in lube oil systems is increasingly vital as industries seek to reduce their environmental impact while enhancing performance. The regeneration of lubricating oil, particularly when combined with waste cooking oil biodiesel and nano additives, presents a promising avenue for improving diesel engine efficiency. The incorporation of nano-additives such as Cerium oxide, Zinc oxide, and Titanium oxide has been shown to optimize fuel characteristics, leading to reduced emissions and superior engine performance. This innovative approach not only addresses fuel sustainability but also promotes the circular economy by utilizing waste materials.

Biodegradable lubricants also play a crucial role in sustainable construction, challenging outdated perceptions regarding their performance and cost-effectiveness. By offering a viable alternative to traditional lubricants, these environmentally friendly options help to minimize ecological footprints while supporting the efficiency of construction operations. Furthermore, the adoption of rigorous environmental and safety management systems, such as ISO standards, enhances the overall sustainability performance of industries, demonstrating that economic growth and environmental stewardship can coexist harmoniously.

Related Posts

-

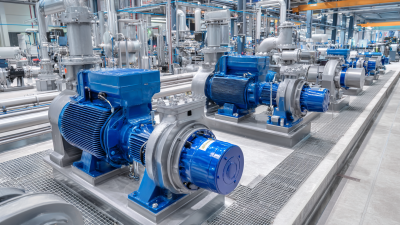

How to Choose the Right Type of Industrial Pump for Your Application

-

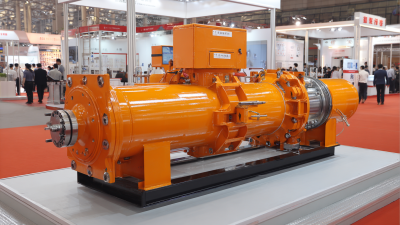

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

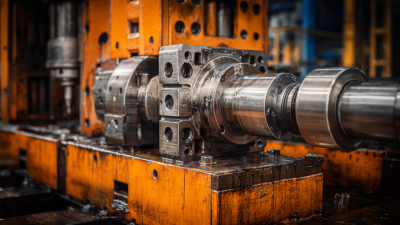

How to Choose the Right Screw Pump for Your Industrial Needs

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China