How to Maximize Efficiency with Screw Pumps in Industrial Applications

Screw pumps have become a vital component in various industrial applications due to their high efficiency and reliability. According to a report by the International Pump Industry Association, the global screw pump market is expected to grow at a CAGR of 5.1% from 2022 to 2030, driven by the increasing demand for reliable pumping solutions in sectors such as oil and gas, chemical processing, and wastewater management. These pumps are particularly favored for their ability to handle viscous fluids, deliver a steady flow rate, and require less maintenance compared to traditional pump types.

In this article, we will explore strategies to maximize efficiency with screw pumps, focusing on optimization techniques, proper installation practices, and maintenance routines that can enhance performance and reduce operational costs in industrial settings.

Understanding the Basics of Screw Pumps in Industrial Settings

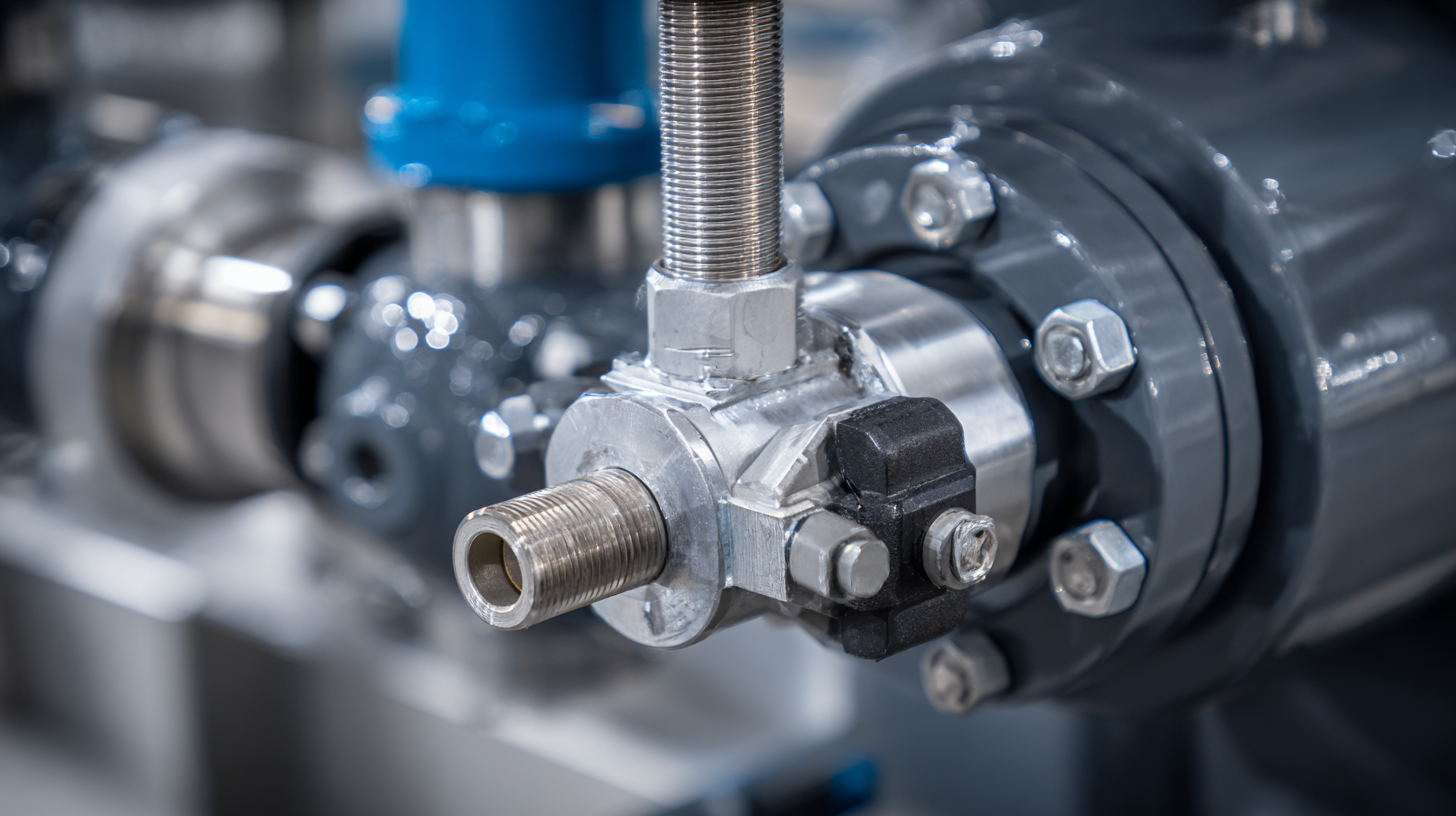

Screw pumps are widely used in various industrial applications due to their efficient handling of viscous fluids and pulsation-free flow. Understanding the fundamentals of how these pumps work is crucial for optimizing their performance and ensuring they meet the demands of specific tasks. Unlike traditional centrifugal pumps, screw pumps utilize a pair of helical screws that interlock to transport fluids through the pump casing, making them ideal for pumping thick liquids and sludges.

**Tip 1:** Regular maintenance is vital for screw pumps to function at their best. Schedule routine inspections to check for wear and tear, ensuring that the screws are properly aligned and lubricated. This preventive measure can significantly extend the lifespan of your equipment.

Moreover, screw pumps are versatile and can handle a wide range of fluids, including those with solid particles. This adaptability makes them an excellent choice for industries like oil and gas, food processing, and wastewater treatment.

**Tip 2:** Implementing flow meters in conjunction with screw pumps can help monitor fluid flow rates accurately. This data allows for better control of the pumping process and helps in identifying any inefficiencies that may arise.

Efficiency of Screw Pumps in Various Industrial Applications

This chart illustrates the efficiency percentage of screw pumps across different industrial applications. The data shows that the food processing industry has the highest efficiency, followed by chemical processing and oil extraction. This highlights the versatility and effectiveness of screw pumps in diverse environments.

Identifying Key Performance Metrics for Screw Pump Efficiency

To maximize efficiency in industrial applications using screw pumps, it is essential to identify and monitor key performance metrics that directly influence their operation. Among these metrics, pump efficiency, energy consumption, and flow rate stand out as critical indicators.

Pump efficiency, often expressed as a percentage, measures how well the pump converts input energy into hydraulic energy, which is crucial for reducing operational costs and improving overall system performance. Regular evaluation of this metric helps identify any deviations from optimal performance and allows for timely maintenance or adjustments.

Energy consumption is another pivotal metric, as it significantly impacts the operational budget. By monitoring energy usage in relation to flow rates, operators can assess the effectiveness of the screw pump while identifying opportunities for energy savings. Moreover, flow rate is essential to understanding the pump's capacity to move fluids under various conditions. Maintaining the desired flow rate while minimizing energy consumption is a key goal, as it ensures that the system remains efficient and responsive to production demands.

Tracking these performance metrics provides valuable insights that enable operators to optimize screw pump usage, enhance reliability, and achieve long-term efficiency in their industrial applications.

Implementing Regular Maintenance Practices to Enhance Screw Pump Longevity

Regular maintenance practices are essential for enhancing the longevity and efficiency of screw pumps in industrial applications. These pumps, known for their reliability and ability to handle viscous fluids, require attention to detail to ensure optimal performance. Scheduled inspections should include checking for leaks, monitoring the integrity of the seals, and ensuring that the rotating elements are well-lubricated. This proactive approach helps in identifying potential issues before they escalate into costly breakdowns.

Moreover, cleaning the pump and its components on a routine basis significantly contributes to its durability. Accumulation of debris and contaminants can lead to abrasion and wear, negatively impacting the pump's efficiency. Implementing a structured maintenance plan that outlines cleaning schedules, lubrication routines, and part replacements, when necessary, will not only enhance the pump's operational lifespan but also improve the overall productivity of the industrial system. By adhering to these best practices, industries can ensure their screw pumps operate smoothly and efficiently for years to come.

How to Maximize Efficiency with Screw Pumps in Industrial Applications

| Parameter | Value | Impact on Efficiency |

|---|---|---|

| Pump Speed (RPM) | 1500 | Optimized flow rate and reduced wear |

| Fluid Viscosity (cP) | 300 | Direct correlation with energy consumption |

| Maintenance Frequency (months) | 3 | Prevents unexpected downtime |

| Operating Temperature (°C) | 60 | Maintains pump integrity and efficiency |

| Seal Condition (% Good) | 85 | Critical for preventing leaks and maintaining flow |

| Power Consumption (kW) | 15 | Lower power usage improves operational costs |

Optimizing Operational Parameters for Maximum Efficiency in Screw Pumps

Screw pumps are essential in numerous industrial applications, and maximizing their efficiency requires a focused approach to operational parameters. An effective strategy involves understanding the nuanced interplay between flow rates, pressure differentials, and the physical characteristics of the materials being pumped. By optimizing these parameters, facilities can significantly enhance the performance and longevity of screw pumps.

Tips for maximizing efficiency include regularly monitoring operational conditions and maintaining an optimal fluid viscosity. Adjusting the pump speed to match the system's needs can prevent unnecessary wear and tear on pump components. Additionally, employing advanced modeling techniques, such as those used in the optimization of ground source heat pumps and positive displacement machines, can provide valuable insights into performance improvements.

Another effective approach is to explore innovations in mechanical design—such as lobe rotor geometry or screw geometry enhancements—that directly influence hydraulic performance. Integrating machine learning algorithms to predict and adjust for isentropic efficiency could lead to further advancements, ensuring that the screw pumps operate at their highest potential in various industrial scenarios.

Integrating Advanced Technologies to Monitor and Improve Screw Pump Performance

In today's industrial landscape, maximizing efficiency in screw pump applications hinges significantly on the integration of advanced monitoring technologies. Recent studies from the Hydraulic Institute indicate that implementing real-time performance tracking can enhance operational efficiency by up to 20%. By utilizing IoT sensors and predictive analytics, operators can proactively monitor key parameters such as flow rate, pressure, and temperature, which enables quick responses to any deviations from optimal performance standards.

In addition, adopting machine learning algorithms to analyze historical performance data allows for the identification of patterns and anomalies. According to a report by Global Industry Analysts, integrating such technologies can lead to a reduction in unscheduled downtime by approximately 15%, translating into substantial cost savings and improved productivity. With the ability to fine-tune screw pump operations based on data-driven insights, industries can not only ensure the longevity of their equipment but also contribute to a more sustainable manufacturing process.