The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

In industrial operations, the effective functioning of machinery is paramount, with lubrication systems playing a critical role in ensuring optimal performance and longevity. Lubrication pumps are integral to this process, providing consistent and precise distribution of lubricant to critical components, thereby reducing friction and wear. According to a report by MarketsandMarkets, the global lubrication systems market is projected to reach USD 27.45 billion by 2025, highlighting the increasing recognition of the importance of proper lubrication in machinery maintenance. Furthermore, the U.S. Department of Energy emphasizes that effective lubrication can improve equipment efficiency by up to 30%, demonstrating the profound impact lubrication pumps have on operational sustainability and cost-effectiveness.

By investing in high-quality lubrication pumps, industries can enhance equipment lifespan, minimize downtime, and optimize production efficiency, underscoring their essential role in today’s competitive landscape.

Understanding the Purpose of Lubrication Pumps in Industrial Applications

Lubrication pumps serve a critical function in numerous industrial applications, primarily by facilitating the efficient distribution of lubricants to machinery components. These pumps ensure that the right amount of lubricant reaches areas that require protection against friction and wear. By maintaining an optimal lubricating film, lubrication pumps not only enhance the performance of equipment but also reduce the likelihood of costly breakdowns.

Moreover, the strategic use of lubrication pumps contributes significantly to energy efficiency. Equipment that operates with proper lubrication experiences less resistance, which translates into lower energy consumption. This not only leads to cost savings for industries but also promotes sustainability by minimizing waste. Understanding the purpose and function of lubrication pumps is essential for maintaining the longevity and reliability of industrial machinery.

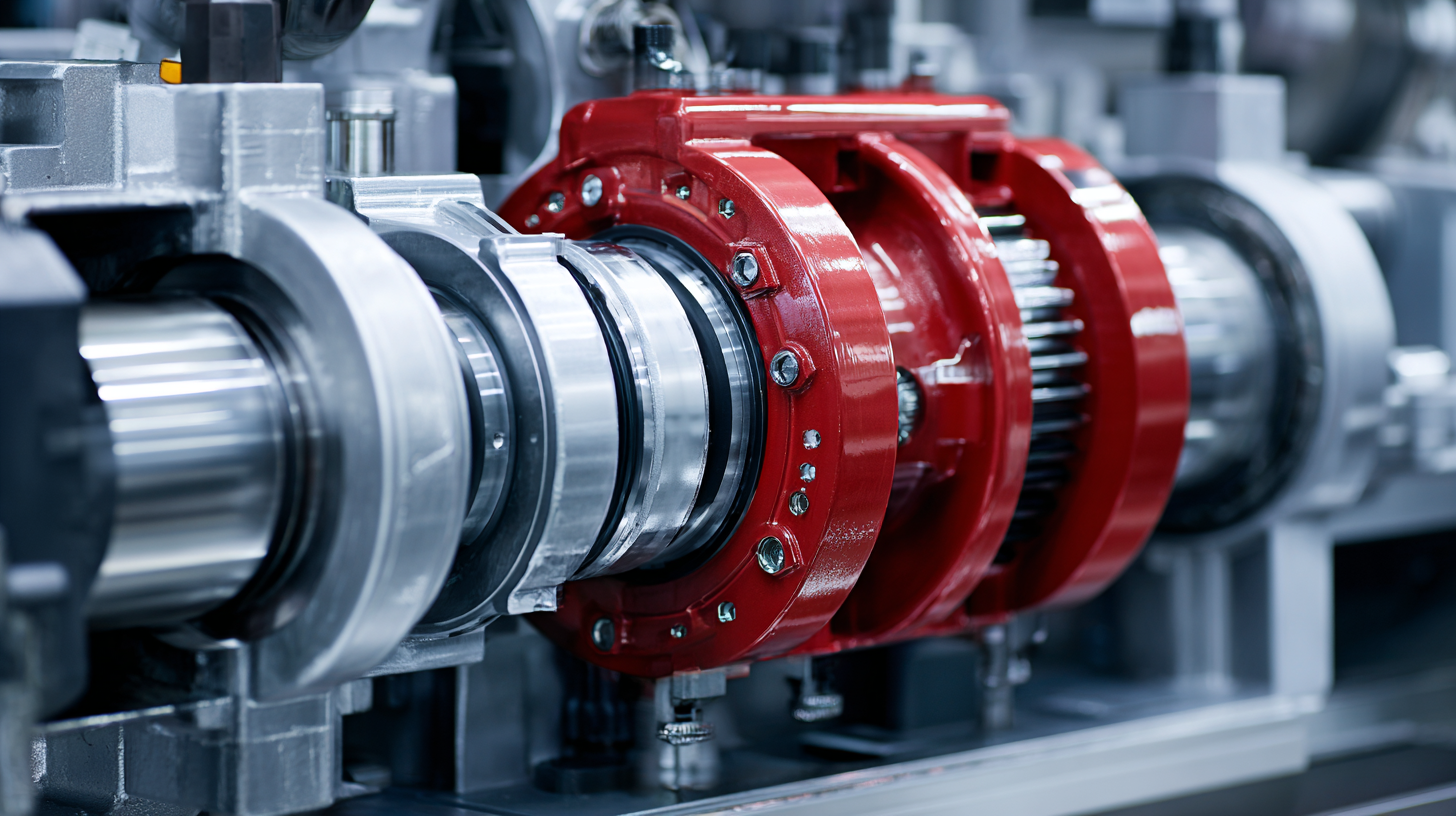

Key Types of Lubrication Pumps and Their Functions

Lubrication pumps play a crucial role in maintaining the efficiency and longevity of equipment across various industries. Understanding the different types of lubrication pumps can help in selecting the right one for specific applications. Common types include gear pumps, diaphragm pumps, and progressive cavity pumps. Gear pumps are favored for their ability to move high-viscosity fluids, making them ideal for heavy machinery. Diaphragm pumps, on the other hand, are perfect for applications requiring precise flow control due to their ability to handle varying volumes without mechanical wear.

Tips: When selecting a lubrication pump, consider the viscosity of the lubricant and the specific pressure requirements of your equipment. Regular maintenance, such as checking for leaks and ensuring proper alignment, can significantly enhance pump performance.

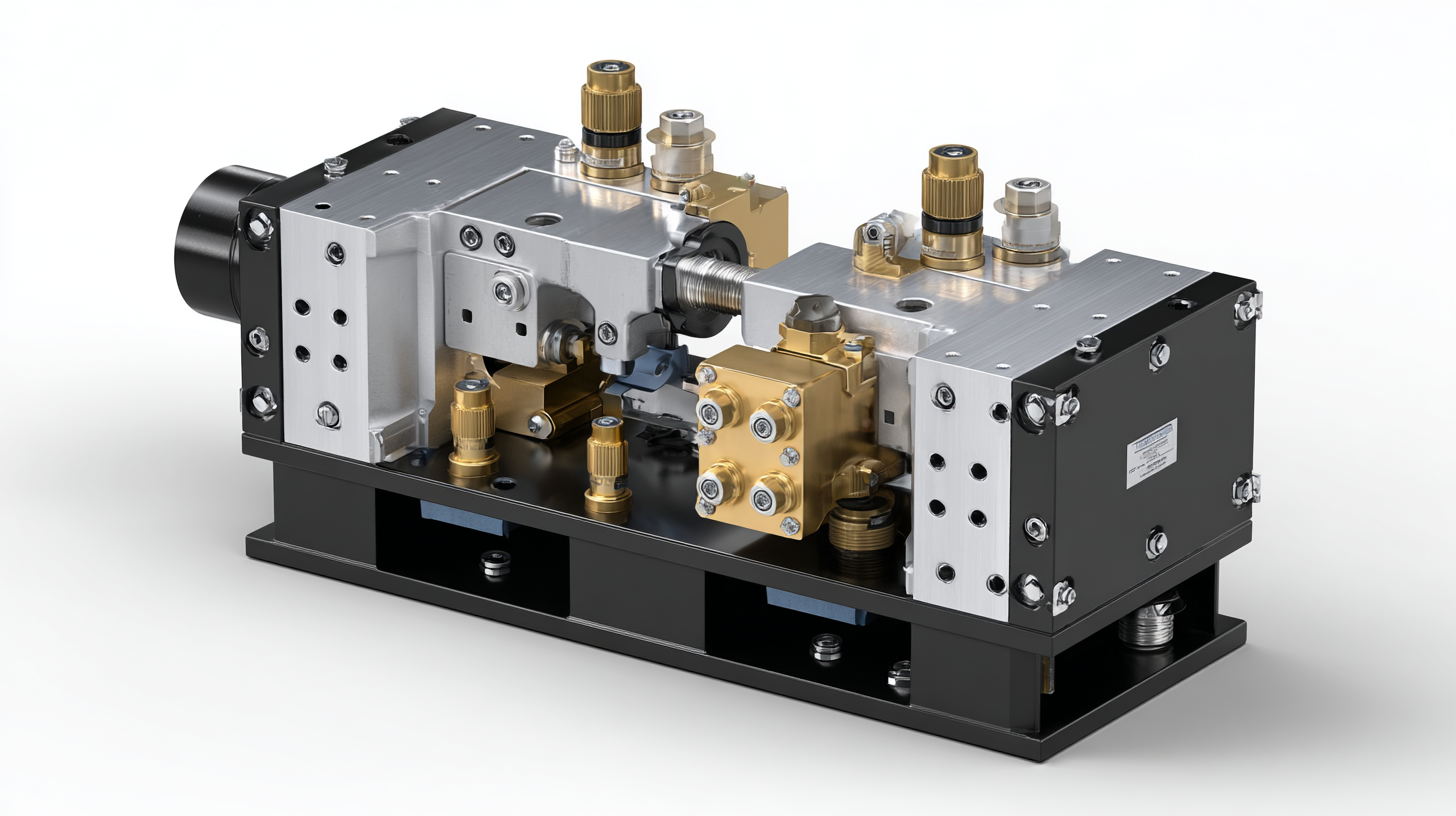

In addition to conventional pump types, progressive lubrication systems are gaining popularity in automated environments. These systems allow for precise delivery of lubricants to multiple points, reducing waste and ensuring optimal lubrication. Understanding the intended application will assist in choosing the right system and achieving maximum efficiency.

Tips: Implement a routine inspection schedule to catch any potential issues early. Properly leveraging the capabilities of your lubrication pump can help streamline your operations and extend the life of your machinery.

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

The Impact of Lubrication on Equipment Performance and Longevity

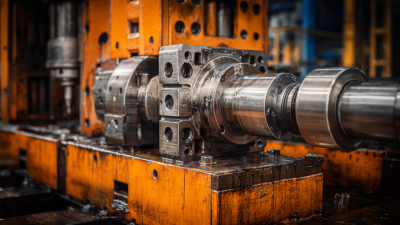

Lubrication plays a crucial role in the performance and longevity of industrial equipment. Proper lubrication minimizes friction between moving parts, reducing wear and tear, which are common culprits behind equipment failure. By ensuring that all components operate smoothly, lubrication not only enhances operational efficiency but also prevents overheating, thereby extending the lifespan of machinery. Regularly maintained lubrication systems help in maintaining the optimal viscosity of lubricants, which is essential for effective protective measures against corrosion and degradation.

Moreover, the positive impacts of lubrication extend beyond mere mechanical function. Consistent application of high-quality lubricants contributes to cleaner running environments, which is vital for sensitive equipment. It also aids in maintaining energy efficiency, as well-lubricated machinery requires less power to operate, leading to significant cost savings over time. Consequently, investing in effective lubrication pumps and systems is not just a maintenance measure; it is a strategic decision that bolsters overall equipment health and ensures sustained productivity in the long run.

Maintenance Best Practices for Lubrication Pumps

Lubrication pumps are crucial in maximizing both the longevity and operational efficiency of machinery. Regular maintenance of these pumps is essential to ensure their effectiveness. Following best practices as outlined in the ICML 55.1 standard can significantly enhance lubricated asset management. It’s not just about ensuring the pumps are working; it’s about embedding a maintenance mindset within the team. This involves proper training and adherence to safety protocols, ensuring that every mobile lube technician is equipped with the necessary knowledge and tools to perform their tasks safely and effectively.

**Tips:**

1. Regularly check for contamination in your lubrication systems, as air and water can substantially degrade lubricants, leading to unexpected equipment failures.

2. Consider conducting routine assessments and audits of your lubrication practices to identify areas for improvement and adherence to industry standards.

3. Make it a habit to inspect lubrication pumps for wear and ensure they are correctly calibrated to maintain optimal performance.

By instilling these practices, organizations can foster a culture that prioritizes maintenance, ultimately enhancing equipment reliability and performance.

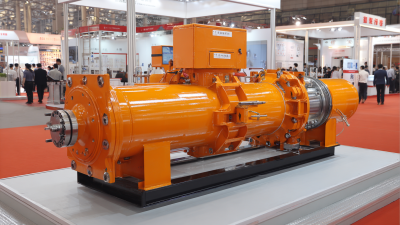

Innovations in Lubrication Pump Technology for Enhanced Efficiency

Advancements in lubrication pump technology have significantly transformed the landscape of industrial efficiency. Modern lubrication pumps are designed to deliver precise amounts of lubricant, ensuring optimal performance of machinery. With innovations such as advanced sensor integration and automatic monitoring systems, these pumps can adapt to fluctuating operational conditions in real-time, reducing waste and improving energy efficiency. This technological evolution minimizes the risk of equipment failure, allowing for longer maintenance intervals and extending the overall lifespan of machinery.

Furthermore, the development of smart lubrication systems has revolutionized how industries approach maintenance scheduling. By utilizing data analytics and IoT connectivity, these systems can predict when equipment requires lubrication based on usage patterns and wear indicators. This proactive approach not only enhances operational efficiency but also supports sustainable practices by minimizing the consumption of lubricants. As industries continue to prioritize efficiency and sustainability, the essential role of innovative lubrication pump technology will only become more pronounced, driving improved productivity and reduced environmental impact.

Related Posts

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines