Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

The 138th Canton Fair in China, scheduled for 2025, is set to showcase groundbreaking advancements in the oil pumping machine industry. As the global demand for efficient energy solutions continues to rise, the oil and gas sector must adapt to changing market dynamics. According to a report by Research and Markets, the oil pumping machine market is projected to grow at a CAGR of 5.6% from 2021 to 2026, driven by increasing exploration activities and technological innovations. This trade fair presents a unique platform for industry leaders and innovators to exhibit their latest technologies, focusing on enhancing operational efficiency and sustainability. With the integration of AI and IoT in oil pumping machines, manufacturers are not only improving productivity but also reducing environmental impact. Thus, the innovations showcased at the Canton Fair are expected to set new benchmarks and steer the future landscape of the oil pumping industry, making it a pivotal event for stakeholders.

Innovative Technologies Showcased in Oil Pumping Machines at Canton Fair 2025

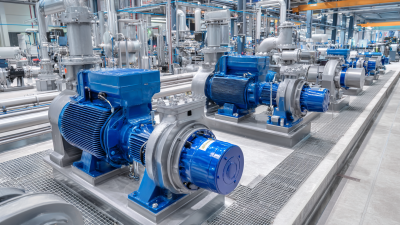

At the 138th Canton Fair 2025, the landscape of oil pumping machines is being transformed with groundbreaking innovations that are set to redefine efficiency and sustainability in the industry. Among the highlighted technologies, advancements in automation, such as AI-driven monitoring systems, are optimizing operational efficiency. According to a recent industry report, automating oil extraction processes can increase productivity by up to 30%, significantly enhancing the bottom line for operators. In addition, the integration of IoT technology enables real-time data analytics, allowing for predictive maintenance and reducing downtime by as much as 25%.

Moreover, exhibitors are showcasing eco-friendly pumping solutions that utilize renewable energy sources. Companies are now developing oil pumps that operate on solar and wind energy, contributing to a decline in carbon emissions. A study by the International Energy Agency (IEA) indicates that transitioning to sustainable technologies in the oil industry could potentially reduce greenhouse gas emissions by 15% by 2030. As these innovations take center stage at the fair, industry stakeholders are keen to explore their potential impacts on future operations.

Tips: When evaluating oil pumping technologies, consider not just the initial investment but also long-term operational savings and environmental impact. Staying updated on regulatory changes related to energy and emissions can help align your investments with future industry standards. Additionally, engaging with technology providers at events like the Canton Fair can provide insights into the latest trends and best practices.

Sustainability and Environmental Impact of Modern Oil Pumping Solutions

At the 138th Canton Fair in 2025, significant advancements in oil pumping machines were showcased, with a clear emphasis on sustainability and environmental impact. Modern oil pumping solutions are increasingly integrating eco-friendly technologies to minimize their carbon footprint. According to a report by the International Energy Agency (IEA), the oil and gas sector is responsible for approximately 20% of global greenhouse gas emissions. The introduction of electric and hybrid electric oil pumps at the fair represents a crucial step towards reducing these emissions, as they not only enhance efficiency but also lower operational costs.

At the 138th Canton Fair in 2025, significant advancements in oil pumping machines were showcased, with a clear emphasis on sustainability and environmental impact. Modern oil pumping solutions are increasingly integrating eco-friendly technologies to minimize their carbon footprint. According to a report by the International Energy Agency (IEA), the oil and gas sector is responsible for approximately 20% of global greenhouse gas emissions. The introduction of electric and hybrid electric oil pumps at the fair represents a crucial step towards reducing these emissions, as they not only enhance efficiency but also lower operational costs.

Moreover, the push for sustainable practices is reflected in the growing adoption of smart pumping systems that utilize artificial intelligence and IoT technologies. A recent study by Markets and Markets predicts that the smart oil field market will reach USD 30 billion by 2026, driven by the need for real-time monitoring and optimization of oil extraction processes. These innovations not only reduce the environmental impact of oil extraction but also ensure compliance with increasingly strict environmental regulations, aligning with global efforts to combat climate change. Thus, the innovations displayed at the Canton Fair underscore a significant shift towards greener practices in the oil sector, promising a more sustainable future.

Key Industry Players and Their Contributions to Oil Pumping Innovations

At the 138th Canton Fair in 2025, industry leaders are showcasing groundbreaking innovations in oil pumping technologies. Key players such as Schlumberger and Halliburton are introducing advanced pumping machines that integrate AI and IoT for enhanced efficiency. According to a report by ResearchAndMarkets, the global oil pumping equipment market is expected to grow at a CAGR of 4.5% from 2023 to 2028, reflecting the ongoing demand for innovative solutions in this sector.

Companies like Weatherford are also making significant contributions with their new designs focusing on energy conservation and reduced operational costs. Their latest oil pumping machine model boasts a 20% increase in energy efficiency, which not only lowers costs but also meets stringent environmental regulations. Industry analysts are noting that these advancements are crucial as the sector seeks sustainable practices amidst rising global energy demands.

The discussions and exhibits at the Canton Fair exemplify how collaboration among these industry leaders is driving innovation and setting new benchmarks for performance and sustainability in oil pumping technologies.

Emerging Trends in Automation for Oil Pumping Equipment

At the 138th Canton Fair in 2025, the spotlight is set to shine on the innovative trends in automation for oil pumping equipment. The oil and gas sector is undergoing a significant transformation, particularly driven by advancements in automation technologies. Reports indicate a stark discrepancy in fossil fuel jobs, where production soared by 47% despite a 17% drop in employment. This emphasizes the critical need for automation to enhance efficiency and productivity in oil pumping operations. The integration of AI into oil and gas projects promises to maximize performance and address sustainability challenges, propelling the industry toward a more automated future.

Moreover, the emergence of IoT and Industry 4.0 technologies is reshaping the landscape of oil pumping machines, allowing for real-time monitoring and predictive maintenance. These innovations promise not only improved operational efficiency but also reduced costs and enhanced safety in oil extraction processes. As companies increasingly adopt these technologies, the potential for automated systems to streamline operations and optimize resource management becomes evident, paving the way for a new era in oil pumping machinery. With a focus on sustainability and enhanced performance, the future of oil pumping equipment is poised for remarkable growth through automation.

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

Future Prospects and Market Opportunities for Oil Pumping Machines Post-2025

The 138th Canton Fair in 2025 showcased a plethora of innovative trends in oil pumping machines, setting the stage for significant market advancements post-2025. As global demand for efficient energy solutions rises, manufacturers are increasingly focused on integrating smart technologies with traditional pumping systems. This not only enhances operational efficiency but also minimizes energy consumption, catering to the growing emphasis on sustainability in the oil industry.

Looking forward, the potential market opportunities for oil pumping machines appear promising. Emerging economies in Asia and Africa present lucrative prospects as they expand their energy infrastructures. Furthermore, advancements in automation and AI are expected to drive the development of more intelligent and adaptable pumping systems. Companies that can leverage these innovations while maintaining cost-effectiveness will likely dominate the market in the coming years, positioning themselves as leaders in this evolving industry landscape.

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

| Feature | Current Trends | Future Prospects | Market Opportunities |

|---|---|---|---|

| Smart Technology Integration | Use of IoT for remote monitoring and control | Enhanced automation and predictive maintenance | Increased investments in smart oilfield solutions |

| Eco-friendly Solutions | Development of electric and hybrid pumps | Regulations favoring sustainable technologies | Growth in markets prioritizing sustainability |

| Increased Efficiency | Optimization of pump designs for energy savings | Higher performance standards and regulations | Partnerships for technology enhancements |

| Data Analytics | Implementation of big data for operational insights | Predictive analytics for resource management | Opportunities in data-driven decision making |

| Modular Design | Flexibility in configurations for various applications | Adaptability to shifting market demands | Access to diverse market segments |