Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data

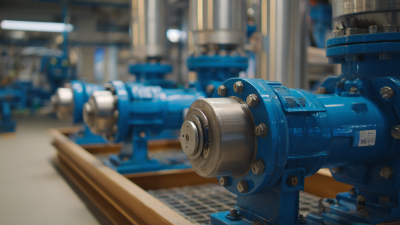

In the realm of industrial machinery, the significance of effective lubrication cannot be overstated. Oil lubrication pumps play a pivotal role in ensuring that equipment operates smoothly and efficiently, minimizing wear and tear that can lead to costly downtime. As noted by industry expert Dr. Michael Thompson, a leading authority in lubrication technology, "Proper oil management through the use of advanced oil lubrication pumps is essential to extending the lifespan of machinery." This underscores the vital connection between lubrication methods and equipment longevity.

Understanding the intricacies of oil lubrication pumps not only aids in selecting the right system but also enhances overall operational reliability. The integration of real-time monitoring and data analytics has revolutionized how industries approach lubrication, enabling proactive maintenance strategies that can prevent unexpected failures. By leveraging insights gained from these technologies, organizations can make informed decisions that optimize both productivity and equipment performance.

As we delve deeper into this discussion, we will explore key insights into the impact of oil lubrication pumps on machinery longevity. This analysis will be supported by data highlighting the tangible benefits of investing in high-quality lubrication systems, ultimately demonstrating that proactive management of oil lubrication not only safeguards asset integrity but also drives long-term profitability.

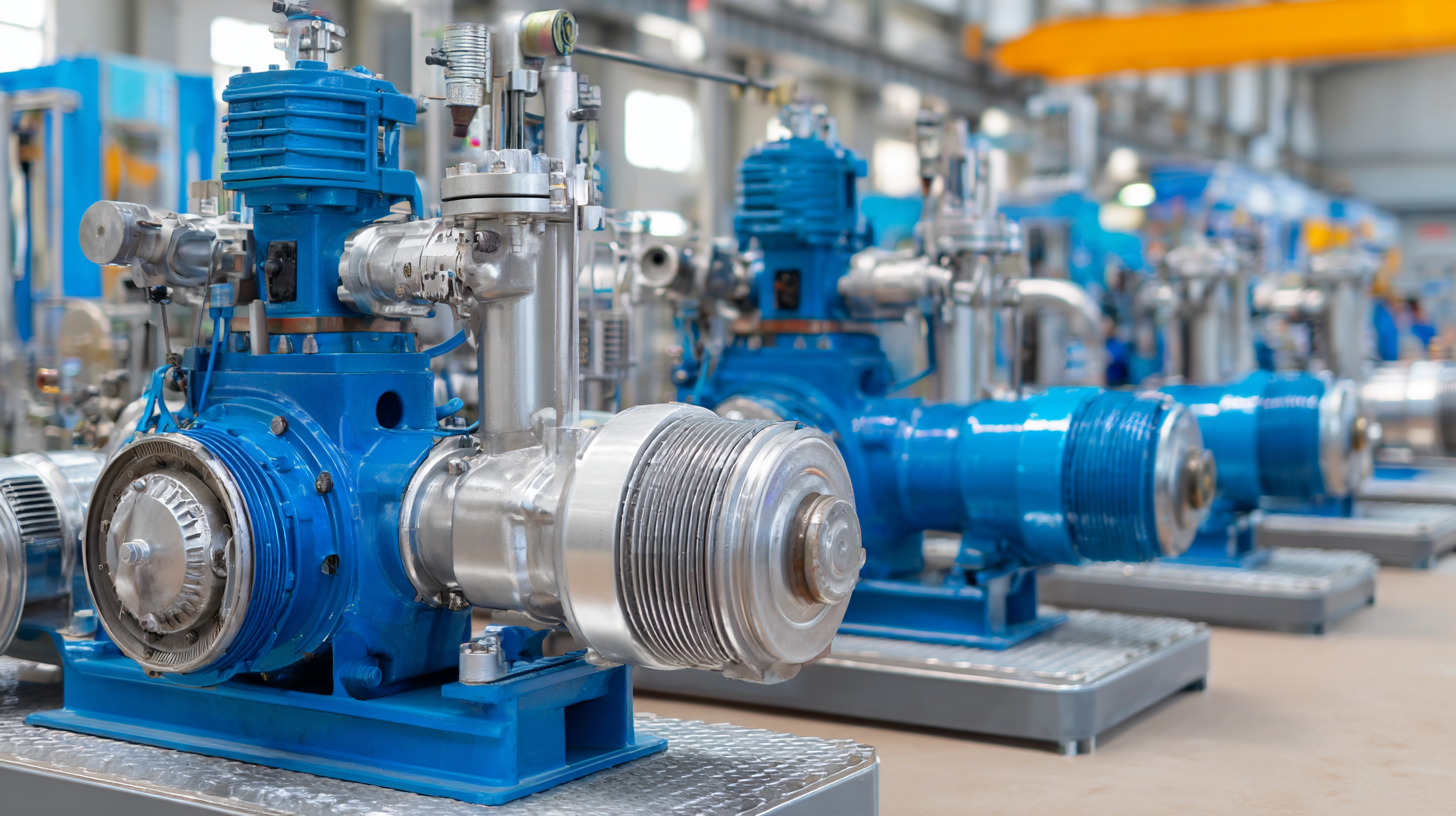

The Role of Oil Lubrication Pumps in Reducing Equipment Wear: A Technical Overview

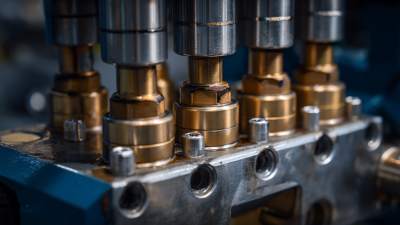

Oil lubrication pumps play a crucial role in the overall performance and longevity of machinery by significantly reducing equipment wear. By supplying a steady flow of high-quality lubricants, these pumps ensure that moving parts operate smoothly, minimizing metal-to-metal contact that often leads to premature deterioration. Recent advancements in lubricants integrate proprietary additives designed to enhance protection and reduce wear, which is essential for maintaining operational efficiency in both industrial and agricultural equipment.

Oil lubrication pumps play a crucial role in the overall performance and longevity of machinery by significantly reducing equipment wear. By supplying a steady flow of high-quality lubricants, these pumps ensure that moving parts operate smoothly, minimizing metal-to-metal contact that often leads to premature deterioration. Recent advancements in lubricants integrate proprietary additives designed to enhance protection and reduce wear, which is essential for maintaining operational efficiency in both industrial and agricultural equipment.

Moreover, the implementation of condition monitoring technologies, such as electrical impedance measurements, provides valuable insights into the state of lubricated components. This approach enables real-time analysis with improved data quality, facilitating timely maintenance actions that can prevent catastrophic failures. Overall, the strategic application of advanced lubrication systems and proactive monitoring not only boosts the reliability of machinery but also extends its service life, resulting in significant cost savings for industries reliant on heavy-duty performance.

Analyzing the Relationship Between Pump Efficiency and Machinery Lifespan Metrics

The efficiency of oil lubrication pumps plays a critical role in determining the lifespan of machinery. According to a report by the American Society of Mechanical Engineers (ASME), improving pump efficiency by just 5% can extend equipment life by up to 20%. This correlation is largely due to reduced friction and heat generation, which are significant contributors to wear and tear. Machinery operating with high-efficiency pumps benefit from consistent oil flow, ensuring optimal lubrication at all times, which is fundamental in minimizing component degradation.

Moreover, a study published in the Journal of Tribology indicated that equipment using inefficient lubrication systems experiences a 30% increase in maintenance costs and a significant decrease in operational reliability. It was found that machinery longevity is directly affected, with less efficient oil pumps leading to a higher rate of component failures. As industry standards continue to prioritize operational efficiency and equipment durability, investing in advanced lubrication technologies becomes crucial not only for optimal performance but also for maximizing the lifespan of critical machinery assets.

Evaluating Industry Statistics on Oil Pump Failures and Their Maintenance Costs

Oil lubrication pumps play a crucial role in maintaining the efficiency and longevity of industrial equipment. However, industry statistics reveal a concerning trend regarding oil pump failures. According to a recent study by the International Journal of Industrial Systems, nearly 30% of machinery failures can be attributed to lubrication system issues, with oil pumps being a significant component. The estimated maintenance costs associated with these failures can exceed 15% of total operational expenses for manufacturing facilities, highlighting the need for proactive maintenance and monitoring strategies.

To mitigate these costs, regular inspections and predictive maintenance are essential. Implementing condition monitoring can significantly reduce unplanned downtimes. For instance, the ASTM International reported that companies utilizing advanced diagnostic tools saw a 25% reduction in maintenance costs over a three-year period. By strategically scheduling maintenance based on the operational data of oil pumps rather than relying on standard time intervals, organizations can optimize their resources and extend the lifespan of their equipment.

**Tips:** Regularly check oil pump performance metrics to identify anomalies early. Consider investing in automated monitoring systems that provide real-time data, helping to predict failures before they occur. Additionally, ensure that all maintenance personnel are well-trained in lubrication best practices to enhance overall efficiency.

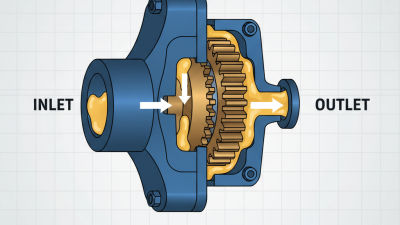

Comparative Study: Oil Lubrication vs. Other Lubrication Methods in Equipment Durability

The comparative analysis of oil lubrication and other lubrication methods reveals significant differences in their impact on equipment durability. Oil lubrication systems are designed to provide a consistent and effective barrier between moving parts, reducing friction and wear. This effectiveness can lead to increased equipment longevity, particularly in high-load and high-speed applications where other lubrication types might fail. By maintaining optimal operating conditions, oil lubrication can extend service intervals and reduce maintenance costs, ensuring that machinery runs more efficiently over time.

In contrast, alternatives such as grease or solid lubricants may excel in specific situations, yet they often fall short in fostering the same level of protection under extreme conditions. Grease, for instance, can lead to increased friction and overheating if not applied correctly. Additionally, while some modern lubes offer convenience, their performance in terms of durability may not meet the standards set by traditional oil lubricants, especially in heavy machinery and industrial applications. Therefore, understanding the nuances between these lubrication methods is crucial for industries aiming to maximize equipment longevity and operational efficiency.

Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data - Comparative Study: Oil Lubrication vs. Other Lubrication Methods in Equipment Durability

| Lubrication Method | Average Equipment Lifespan (Years) | Maintenance Frequency (Months) | Failure Rate (%) | Operational Efficiency (%) |

|---|---|---|---|---|

| Oil Lubrication | 12 | 6 | 5 | 92 |

| Grease Lubrication | 8 | 12 | 10 | 85 |

| Dry Lubrication | 6 | 18 | 15 | 78 |

| Fluid Film Lubrication | 10 | 9 | 8 | 90 |

| Solid Lubrication | 5 | 24 | 20 | 70 |

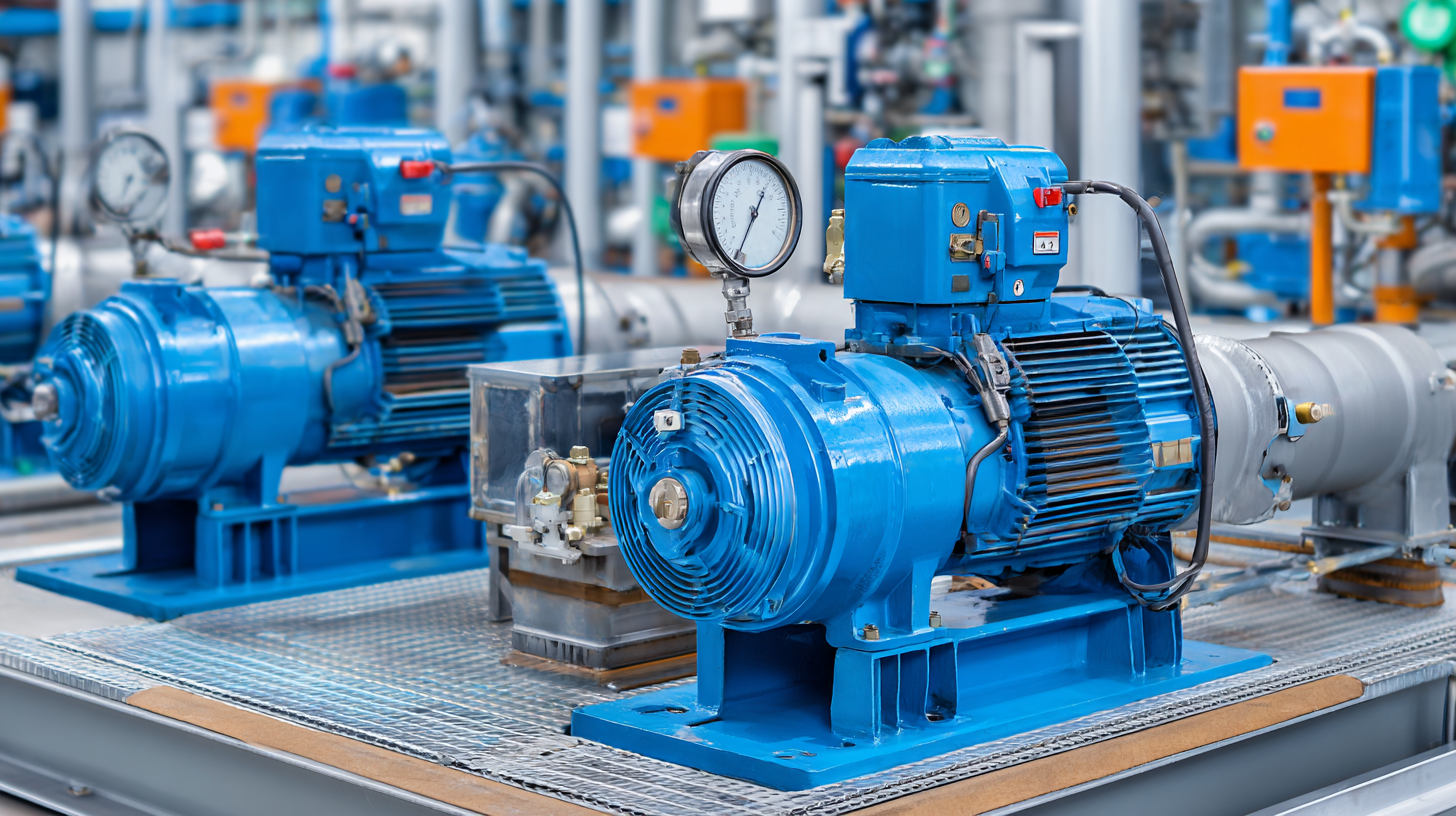

Best Practices for Oil Pump Maintenance to Maximize Operational Reliability and Longevity

Oil lubrication pumps play a crucial role in the longevity and operational reliability of industrial equipment. Effective maintenance practices for these pumps can significantly reduce downtime, enhance equipment performance, and extend their lifespan. According to a report by the Machinery Lubrication Association, regular maintenance can result in a 30% decrease in equipment failure rates, emphasizing the importance of proactive care. Key practices include routine inspection of the pump and its components, regular oil quality analysis, and adherence to manufacturer-recommended service intervals.

Additionally, implementing a condition-based monitoring system can provide early warnings of potential failures, allowing operators to address issues before they escalate. Research from the Society of Tribologists and Lubrication Engineers indicates that proactive maintenance strategies could improve pump reliability by up to 40%, effectively reducing overall maintenance costs and operational disruptions. By focusing on these best practices, organizations can ensure that their oil lubrication pumps function optimally, thereby enhancing the longevity and reliability of their equipment.

Impact of Oil Lubrication Pumps on Equipment Longevity

This chart illustrates the impact of oil lubrication pump maintenance quality on the longevity of equipment. Data shows that excellent maintenance can yield up to 15 years of operation, while poor maintenance significantly reduces longevity to just 2 years.

Related Posts

-

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

Understanding the Benefits of Screw Pumps in Modern Industrial Applications