Unlock the Power of High Pressure Screw Pumps: Applications and Benefits Explained

The utilization of high pressure screw pumps is transforming various industries, enabling enhanced efficiency and reliability in fluid transfer applications. As industry expert Dr. Emily Sanders, a recognized leader in pump technology, aptly puts it, “High pressure screw pumps are not just a solution; they represent a significant advancement in how we manage fluid dynamics under demanding conditions.” This innovation caters to a wide array of sectors, from petrochemicals to food processing, where consistent pressure and flow rate are critical.

In the upcoming years, the demand for high pressure screw pumps is set to soar, driven by the increasing need for effective and sustainable solutions in manufacturing processes. Their robust design and versatility make them ideal for applications that require the transport of viscous fluids and slurries under high pressure. By adopting high pressure screw pumps, industries can leverage their operational potential, leading to cost savings and improved system performance.

As we delve into the top ten benefits and applications of high pressure screw pumps in 2025, it becomes evident that embracing this technology will not only streamline operations but also pave the way for innovation in fluid handling systems. Understanding their capabilities is crucial for businesses aiming to stay ahead in their respective fields.

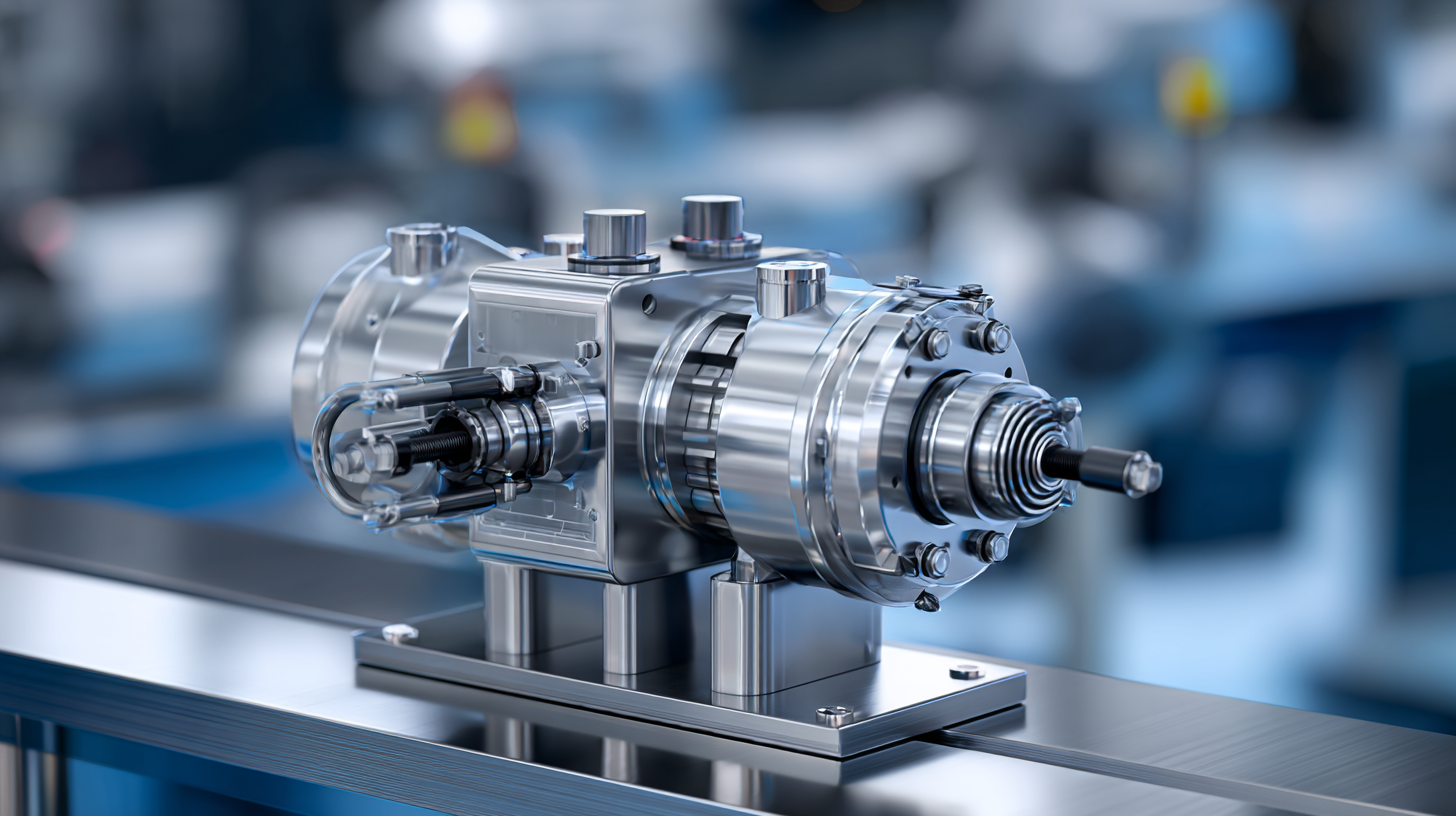

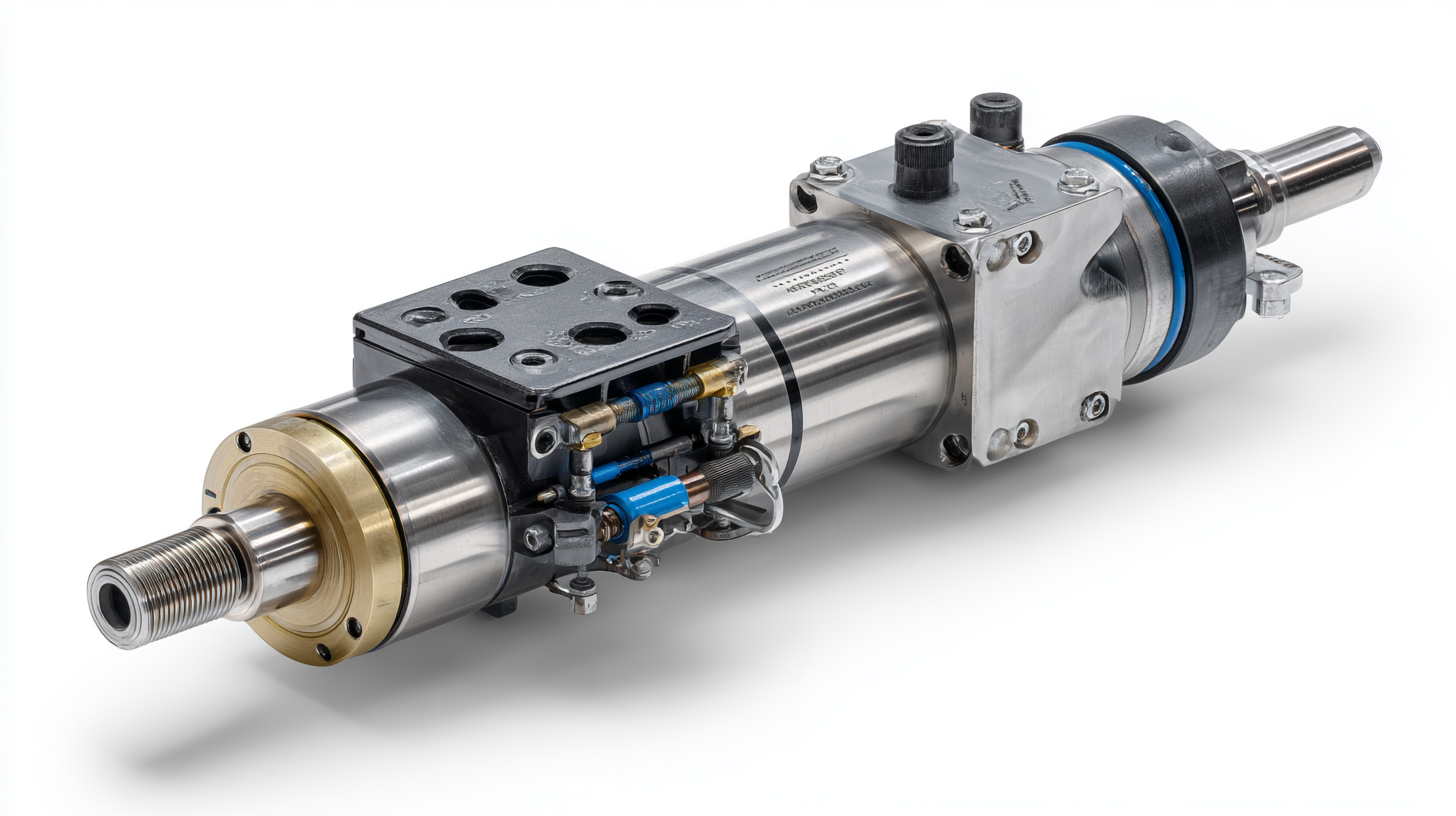

Exploring the Basics of High Pressure Screw Pumps and Their Design Innovations

High pressure screw pumps are becoming increasingly vital in various industrial applications due to their unique design and operational advantages. These pumps feature a helical screw mechanism that allows for smooth and continuous fluid transfer, making them ideal for handling viscous liquids and high-pressure applications. Recent innovations in pump design have focused on enhancing efficiency, reducing maintenance costs, and improving reliability. According to industry reports, the global pump market is expected to reach approximately $90 billion by 2025, with screw pumps playing a significant role in this growth due to their high performance and flexibility in various sectors including oil and gas, chemical processing, and water treatment.

Furthermore, as trends in hydropower evolve, the integration of advanced technologies into high-pressure systems is paramount. Modernized pumped storage solutions, which make use of high-pressure screw pumps, have shown to improve operational efficiency by up to 30%. The shift towards smart technologies in this domain, driven by Industry 4.0 and machine learning applications, not only optimizes performance but also enhances system monitoring and predictive maintenance capabilities. These innovations not only streamline operations but also contribute to reduced downtime and overall increased productivity, reflecting the growing demand for reliability within the energy and industrial sectors.

Applications and Benefits of High Pressure Screw Pumps

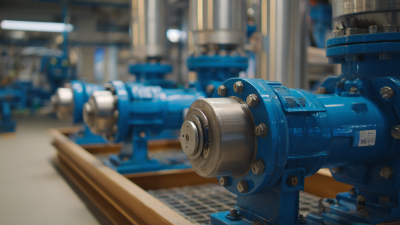

Key Applications of High Pressure Screw Pumps Across Various Industries

High pressure screw pumps are increasingly important in various industries due to their efficiency and versatility. These pumps are capable of handling viscous fluids and providing a consistent flow rate under high pressure, making them ideal for applications in sectors such as oil and gas, food processing, and chemical manufacturing. According to a recent industry report, the demand for high-pressure screw pumps is projected to grow at a CAGR of over 5% in the next five years, driven by the need for more efficient fluid transport solutions.

One key application of high pressure screw pumps is in the oil and gas industry, where they are used for transporting crude oil from production sites to refineries. Their ability to maintain high pressure over long distances minimizes energy loss and enhances operational efficiency. In the food processing industry, these pumps ensure the safe and hygienic movement of edible oils and other viscous materials, meeting stringent health regulations while maintaining product integrity.

**Tips:** When selecting a high pressure screw pump, consider the viscosity of the fluid and the specific pressure requirements of your application. Regular maintenance of the pump can prolong its lifespan and enhance performance. Ensure that your pump is compatible with the fluids being handled to avoid material degradation and leakage issues.

Benefits of Using High Pressure Screw Pumps: Efficiency and Reliability

High pressure screw pumps have emerged as pivotal components in various industrial applications, especially where efficiency and reliability are paramount. These pumps are known for their ability to handle high viscosity fluids and provide consistent flow rates under varying pressure conditions.

According to a report by Research and Markets, the global screw pump market is expected to reach $4.5 billion by 2025, signifying an increasing reliance on these systems in sectors such as oil and gas, chemical processing, and maritime industries.

One of the primary benefits of high pressure screw pumps is their operational efficiency. They are designed to minimize energy consumption while maximizing output, with some models achieving efficiencies upwards of 90%.

This not only reduces operational costs but also supports environmental sustainability initiatives by decreasing the carbon footprint of pumping operations.

Furthermore, high pressure screw pumps exhibit a longer lifespan and lower maintenance needs compared to traditional pumps, which translates to higher reliability and reduced downtime.

Data from the Hydraulic Institute states that maintenance costs can be reduced by up to 30% when using advanced screw pump technologies, further enhancing their appeal to industries focused on optimizing productivity and operational performance.

Comparative Analysis: High Pressure Screw Pumps vs. Other Pump Types

High pressure screw pumps have gained considerable attention in various industrial applications due to their unique operational characteristics. When comparing them to other pump types, such as centrifugal and positive displacement pumps, several advantages emerge. Screw pumps excel in handling highly viscous fluids and can maintain a consistent flow rate regardless of pressure variations, making them ideal for applications that require reliability, such as in the oil and gas industry.

High pressure screw pumps have gained considerable attention in various industrial applications due to their unique operational characteristics. When comparing them to other pump types, such as centrifugal and positive displacement pumps, several advantages emerge. Screw pumps excel in handling highly viscous fluids and can maintain a consistent flow rate regardless of pressure variations, making them ideal for applications that require reliability, such as in the oil and gas industry.

In contrast, centrifugal pumps may struggle with viscous fluids and can suffer from a drop in efficiency at high pressures. Positive displacement pumps, while effective for similar applications, often have more complex maintenance requirements. The design of screw pumps, featuring fewer moving parts, allows for smoother operation and decreased wear over time, translating to lower maintenance costs. Furthermore, their ability to manage a wide range of flow rates and pressures makes them a versatile choice in sectors ranging from chemical processing to food production.

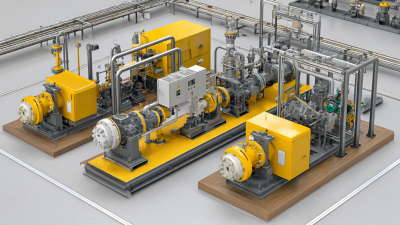

Future Trends and Developments in High Pressure Screw Pump Technology

The future of high pressure screw pump technology is poised for significant advancements, driven by the increasing demand for efficiency and sustainability across numerous industrial applications. According to a recent report by MarketsandMarkets, the global screw pump market is projected to reach USD 3.6 billion by 2026, growing at a CAGR of approximately 4.5%. This growth is attributed to the rising adoption of these pumps in sectors such as oil and gas, chemical processing, and water treatment, where their ability to handle viscous fluids at high pressures is highly valued.

Innovations in materials and design are also influencing the evolution of high pressure screw pumps. The development of advanced composites and coatings is enhancing the durability and performance of these pumps, making them more resistant to wear and corrosion. Furthermore, the integration of IoT technologies is enabling real-time monitoring and diagnostics, which can significantly reduce downtime and maintenance costs. According to a study by ResearchAndMarkets, implementing smart technologies in pump systems could increase operational efficiency by up to 30%. As industries continue to embrace digital transformation, high pressure screw pumps will undoubtedly play a pivotal role in achieving operational excellence and environmental sustainability.

Unlock the Power of High Pressure Screw Pumps: Applications and Benefits Explained - Future Trends and Developments in High Pressure Screw Pump Technology

| Application Area | Benefits | Future Trends | Recent Developments |

|---|---|---|---|

| Oil and Gas | Efficient fluid handling, reduced maintenance costs | Increased automation and IoT integration | Advancements in materials for improved durability |

| Water Treatment | Enhanced reliability and energy efficiency | Focus on sustainable practices and recycling | Development of smart pump systems |

| Chemical Processing | Consistent flow rates and reduced shear stress | Adoption of more corrosion-resistant materials | Innovations in pump design for high-viscosity fluids |

| Food and Beverage | Safe and hygienic handling of products | Increasing focus on hygiene and food safety | Implementation of traceability technologies |

| Mining and Minerals | Robust handling of abrasive materials | Shift towards remote monitoring and control | Enhanced performance in extreme conditions |

Related Posts

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China