Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity

Effective pump lubrication is critical to ensuring the efficiency and longevity of industrial pumps, as substantiated by recent data from the International Pump Users Symposium, which reveals that improper lubrication can lead to an increase in operational costs by up to 30% and significantly reduce the lifespan of pumping equipment. In the competitive landscape of manufacturing and processing, optimizing pump lubrication practices not only improves equipment reliability but also enhances overall productivity, translating to better profit margins. The American Society of Mechanical Engineers (ASME) reports that regular and proper lubrication can decrease wear and tear, thereby cutting down downtime and maintenance expenses by 20%. This guide aims to provide essential insights into best practices for pump lubrication, empowering operators and maintenance personnel to implement strategies that maximize efficiency and promote the durability of their pumping systems.

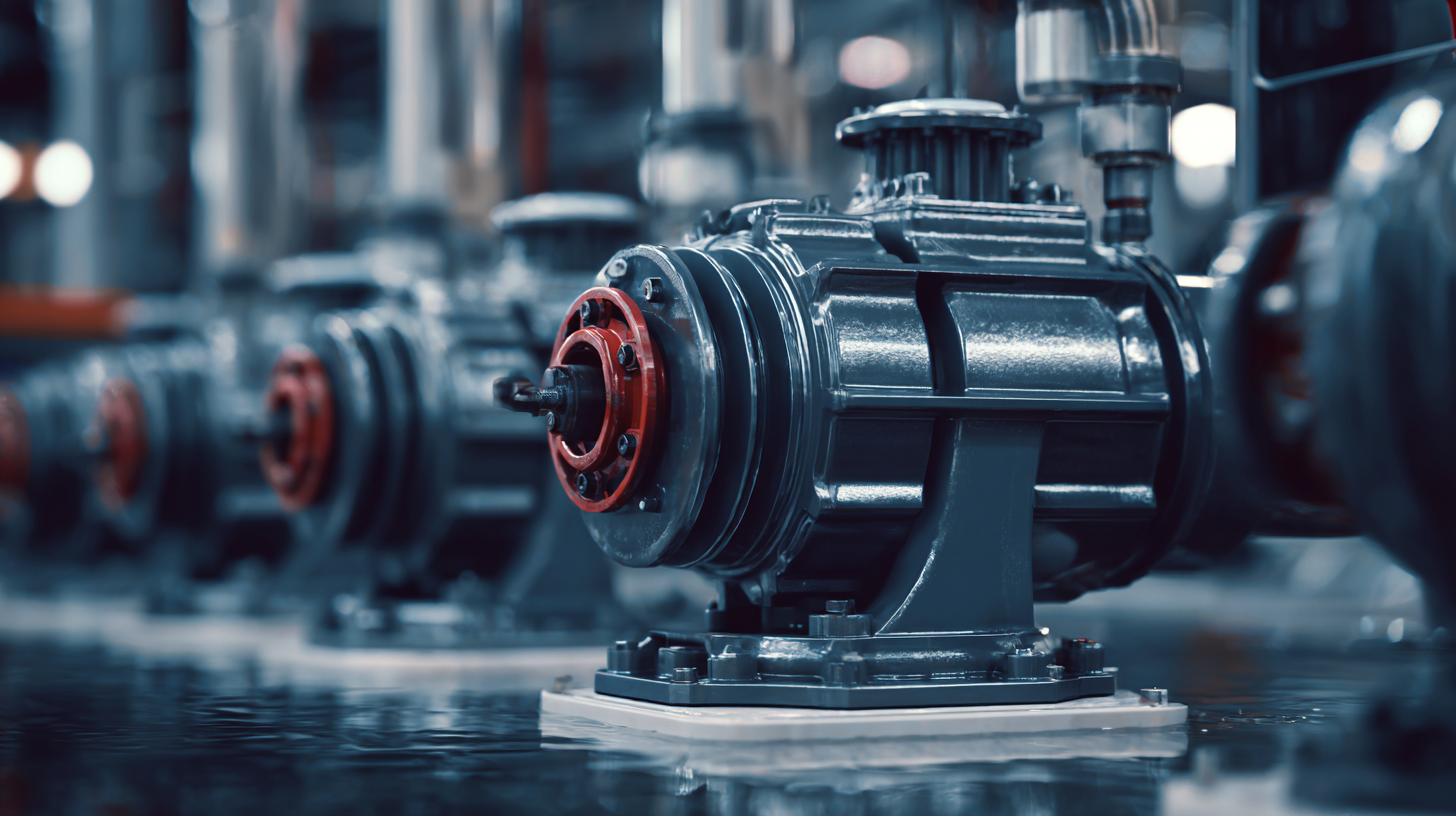

Understanding the Importance of Proper Pump Lubrication

Proper pump lubrication is critical for ensuring the efficient operation and longevity of pumping equipment. Lubrication not only reduces friction between moving parts but also minimizes wear and tear, ultimately leading to better performance and reduced downtime. When pumps operate with adequate lubrication, they can achieve optimal temperatures and function with greater efficiency, which is essential in various industrial applications.

Proper pump lubrication is critical for ensuring the efficient operation and longevity of pumping equipment. Lubrication not only reduces friction between moving parts but also minimizes wear and tear, ultimately leading to better performance and reduced downtime. When pumps operate with adequate lubrication, they can achieve optimal temperatures and function with greater efficiency, which is essential in various industrial applications.

Tips for Effective Pump Lubrication:

- Regularly check and maintain lubrication levels to avoid dry running conditions.

- Use the right type of lubricant that is compatible with your pump’s materials and operating environment to prevent chemical degradation.

- Implement a lubrication schedule based on pump operating hours and workload to ensure consistent application of lubricant.

Understanding the importance of this maintenance routine can significantly reduce the risk of unexpected failures. By prioritizing proper lubrication practices, you not only enhance the functionality of your pumps but also facilitate a safer and more reliable work environment.

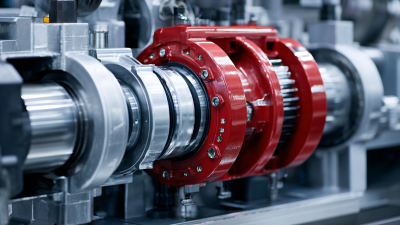

Key Factors Influencing Pump Lubrication Efficiency

Proper pump lubrication is crucial for maximizing operational efficiency and prolonging equipment life. Several key factors influence the effectiveness of lubrication systems, starting with the choice of lubricant. The viscosity of the lubricant is essential; it must be compatible with the pump’s operational temperature and pressure ranges. A lubricant with an inappropriate viscosity can either lead to excessive friction or inadequate lubrication, both of which can result in increased wear and reduced efficiency.

Another significant factor is the lubrication method employed. Whether using oil mist, grease, or automated lubrication systems, each method has its advantages and shortcomings. For example, oil mist lubrication can provide continuous and even coverage, reducing the chances of oil starvation in critical areas. Additionally, regular monitoring and maintenance of lubrication systems are vital. Ensuring that the lubricant remains clean and free from contaminants prevents the buildup of debris that can damage pump internals. These elements combined create a robust lubrication strategy that directly enhances the efficiency and longevity of pump operations.

Common Lubrication Mistakes and Their Impacts on Performance

Proper lubrication is crucial for the efficient operation of pumps. However, many operators fall into common lubrication mistakes that can severely impact performance. One key mistake is using the wrong type or viscosity of lubricant. Each pump has specific lubrication requirements, and failure to adhere to these can lead to increased friction, heat, and ultimately, mechanical failure. Always consult the manufacturer's specifications to ensure you’re using the appropriate lubricant for your pump’s unique conditions.

Another frequent error is neglecting the lubrication schedule. Over-lubricating or under-lubricating a pump can both cause problems. Over-lubrication can lead to excess heat and foaming, while under-lubrication can result in insufficient protection against wear. To avoid these pitfalls, it's essential to establish a consistent lubrication schedule based on operating conditions and the manufacturer's recommendations.

**Tips:** Regularly check lubricant levels and refresh them as needed. Consider implementing a monitoring system that alerts you when lubrication is due. Lastly, maintain a clean lubrication environment to prevent contamination, which can significantly degrade lubricant performance.

Essential Guide to Optimal Pump Lubrication: Performance Impact of Common Mistakes

This chart demonstrates the impact of common lubrication mistakes on pump efficiency and longevity. The data reflects various types of mistakes and their corresponding effect on performance, measured in percentage loss of efficiency.

Best Practices for Maintaining Optimal Lubrication Levels

Proper lubrication is vital for maintaining optimal performance in pumps, directly impacting their efficiency and longevity. According to a report by the American Society of Mechanical Engineers (ASME), ineffective lubrication can lead to a 40% reduction in pump efficiency due to increased friction and wear. Therefore, adhering to best practices for lubrication maintenance is essential for sustainable operations.

Regular monitoring of lubrication levels is crucial; research published in the Journal of Mechanical Engineering shows that pumps operating with inadequate lubrication can experience up to 70% more failures. Operators should establish a routine check on oil levels, contamination, and viscosity, ideally leveraging automated monitoring systems to ensure timely interventions. Furthermore, selecting the right lubricant type is equally important. A study from the Society of Tribologists and Lubrication Engineers (STLE) highlights that synthetic lubricants can extend the life of pump components by up to 50% compared to conventional oils.

Incorporating these best practices into a maintenance schedule not only enhances pump performance but also reduces downtime and repair costs. Implementing a comprehensive lubrication management program can lead to significant improvements in operational efficiency and extend the lifecycle of industrial pumps.

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity - Best Practices for Maintaining Optimal Lubrication Levels

| Lubrication Type | Viscosity Grade | Temperature Range (°C) | Change Interval (Months) | Common Applications |

|---|---|---|---|---|

| Mineral Oil | ISO 68 | -10 to 60 | 6 | Industrial Pumps |

| Synthetic Oil | ISO 32 | -20 to 70 | 12 | High-Temperature Applications |

| Biodegradable Oil | ISO 46 | -15 to 50 | 3 | Environmentally Sensitive Areas |

| Grease | NLGI 2 | -20 to 40 | 12 | Bearing Lubrication |

| Water-based Lubricants | N/A | 0 to 40 | 6 | Food Processing Machines |

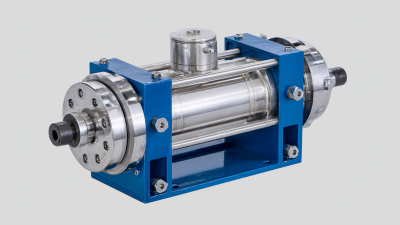

Innovative Lubrication Technologies for Enhanced Pump Longevity

Innovative lubrication technologies play a crucial role in enhancing the longevity and efficiency of pumps in various industrial applications. With advancements in synthetic lubricants and smart lubrication systems, the way pumps are maintained and operated has significantly evolved. These modern solutions not only reduce friction and wear but also optimize the performance of pumps under varying operational conditions. For instance, synthetic lubricants can withstand extreme temperatures and pressures, providing a stable environment that extends the life of essential components.

Moreover, the integration of IoT and real-time monitoring systems in lubrication processes allows for precise tracking of lubricant conditions and pump performance. This proactive approach to lubrication ensures that pumps receive the right type and amount of lubricant at the right time, minimizing downtime and maintenance costs. As industries strive for greater efficiency and sustainability, adopting these innovative lubrication technologies will be vital for maximizing pump longevity and operational success.

Related Posts

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency