The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

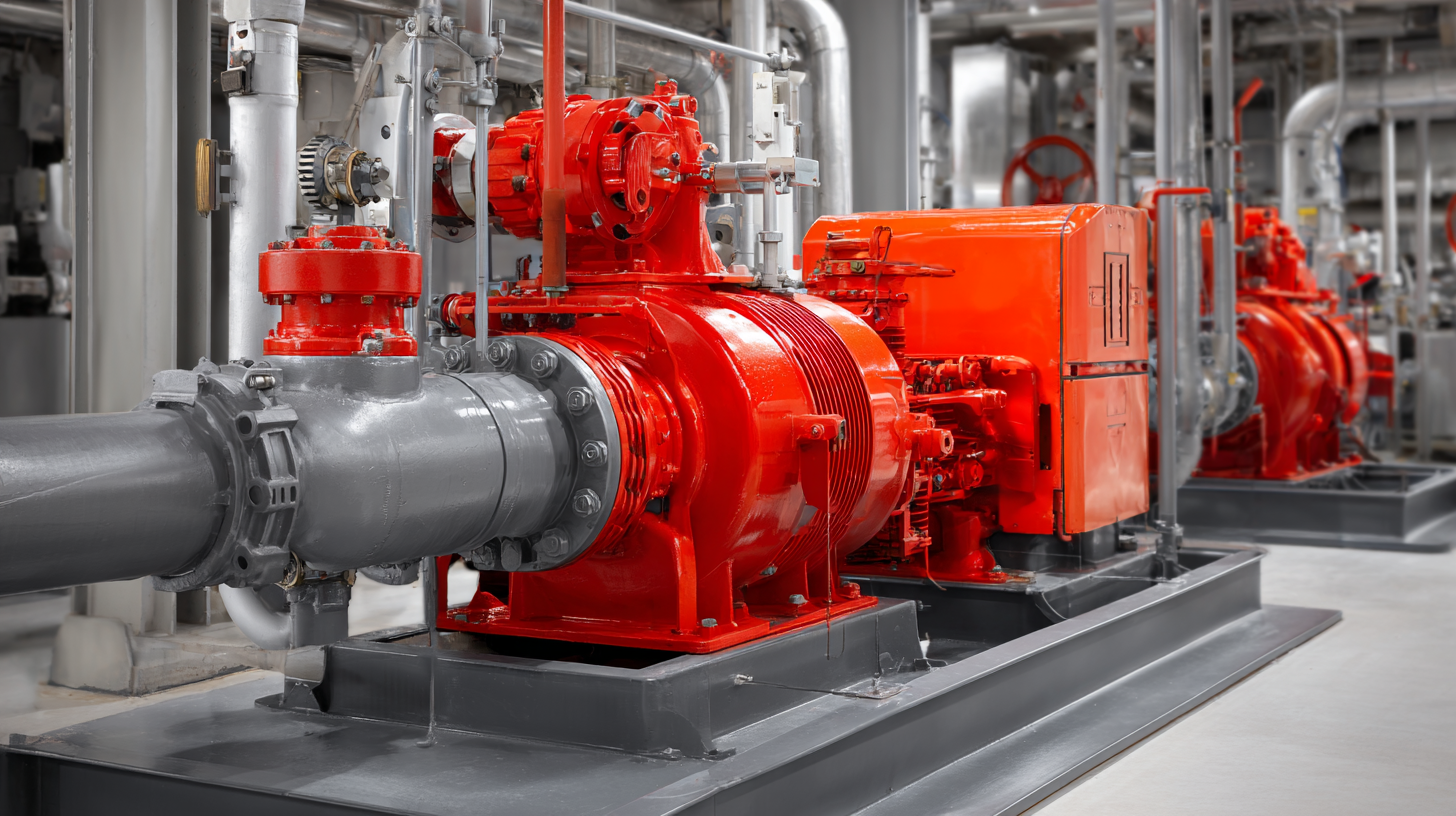

In the world of industrial operations, pump lubrication plays a crucial role in ensuring the efficiency and longevity of equipment. According to recent industry reports, approximately 80% of mechanical failures can be traced back to inadequate lubrication practices. Proper pump lubrication not only reduces friction and wear but also significantly lowers maintenance costs, with studies indicating that effective lubrication can extend equipment life by as much as 50%. Moreover, the improper selection of lubricants and maintenance intervals can lead to inefficient operations, resulting in energy losses that can account for up to 10% of a facility’s total operational costs. This essential guide to pump lubrication will provide you with valuable tips and strategies to enhance the performance of your pumps, ensuring both productivity gains and cost savings in the long run.

Choosing the Right Type of Lubricant for Pump Applications

Choosing the right type of lubricant for pump applications is critical to maximizing operational efficiency and extending equipment life. According to a report by the Machinery Lubrication Association, improper lubrication can lead to a 30% decrease in pump efficiency and a 50% reduction in lifespan. This emphasizes the importance of selecting lubricants that not only reduce friction but also withstand the specific conditions of the pumping environment.

When determining the ideal lubricant, factors such as temperature, pressure, and fluid compatibility must be considered. For instance, synthetic lubricants are often preferred for high-temperature applications due to their superior thermal stability, while biodegradable options are becoming increasingly popular in environmentally sensitive installations. The National Lubricating Grease Institute notes that proper viscosity is crucial; using lubricants with a viscosity that aligns with the pump manufacturer’s specifications can greatly reduce wear and tear, increasing reliability. By prioritizing these factors, operators can significantly improve their pump systems’ performance and longevity.

The Essential Guide to Pump Lubrication: Efficiency by Lubricant Type

This chart illustrates the efficiency ratings of different types of lubricants used in pump applications. The data shows how various lubricants contribute to the overall performance and longevity of pumps.

Understanding Lubrication Frequency: How Often to Lubricate Your Pump

When it comes to the operation of pumps, lubrication frequency plays a crucial role in maximizing both efficiency and longevity. Industry standards suggest that lubrication intervals can vary significantly depending on the pump type, operating conditions, and lubrication used. According to a report by the American Society of Mechanical Engineers (ASME), properly lubricated pumps can improve performance by up to 10% and extend service life by 25% or more.

For most applications, a general rule of thumb for lubrication frequency is to check and lubricate pumps every 500 operating hours. However, in harsher environments or with heavier loads, lubrication may be required more frequently, potentially every 250 hours. The National Lubricating Grease Institute (NLGI) emphasizes that monitoring the pump's operating temperature and vibration levels can provide additional insights into when lubrication is necessary. This proactive approach not only prevents failures but also ensures that the pump operates at optimal performance levels, leading to enhanced productivity in industrial settings.

Additionally, the choice of lubricant significantly influences lubrication frequency. High-quality synthetic oils, for instance, can often last longer and protect better than traditional mineral oils, allowing for extended intervals between applications. A study published in the Journal of Tribology found that using advanced lubricants can reduce wear by nearly 30%, demonstrating the importance of both lubrication frequency and lubricant quality in pump maintenance.

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

| Pump Type | Lubrication Frequency (Hours of Operation) | Recommended Lubricant | Expected Longevity (Years) |

|---|---|---|---|

| Centrifugal Pump | 500 | NLGI Grade 2 Lithium Grease | 10 |

| Positive Displacement Pump | 300 | Multi-purpose Grease | 8 |

| Gear Pump | 200 | ISO VG 32 Oil | 5 |

| Diaphragm Pump | 600 | Synthetic Oil | 12 |

Top 5 Common Pump Lubrication Mistakes and How to Avoid Them

Proper lubrication is crucial for maintaining pump efficiency and extending lifespan. However, many operators fall into common traps that can lead to costly mistakes. One prevalent error is using the wrong type of lubricant. Each pump model may require specific lubrication that matches its components and operating environment. Using an incorrect lubricant can result in inadequate protection or even damage, so it is vital to consult the manufacturer’s recommendations.

Another frequent mistake is neglecting to monitor lubricant levels regularly. Low lubricant levels can lead to overheating, increased friction, and eventual pump failure. Establishing a routine maintenance schedule that includes checking lubricant levels can prevent these issues. Additionally, operators often overlook the importance of cleaning the lubrication system before applying new lubricant. Contaminants can compromise lubricant effectiveness, so thorough cleaning should be a part of the lubrication process.

By being aware of these pitfalls, operators can enhance the reliability and efficiency of their pumps.

3 Key Indicators of Proper Lubrication in Pump Systems

Proper lubrication is crucial for maintaining the efficiency and longevity of pump systems. To ensure optimal performance, there are three key indicators that can help identify whether lubrication is being effectively managed.

Firstly, monitoring temperature is essential; excessive heat can signal insufficient lubrication or inappropriate lubricant choice. A consistent and appropriate operating temperature typically indicates that lubrication is being handled correctly, protecting the pump from wear and tear.

Secondly, assessing vibration levels can provide insight into the health of the pump’s lubrication system. Increased vibration can point to issues like misalignment or imbalance but may also indicate that lubrication is not adequately reducing friction between moving parts. Regular vibration analysis can help detect these changes early, allowing for timely maintenance before serious damage occurs.

Lastly, observing the condition of the lubricant itself is vital. Contaminants in the lubricant, such as dirt or water, can severely compromise lubrication efficacy. Regularly inspecting and sampling lubricants for contamination or degradation ensures the pump system operates smoothly, thereby extending its service life and enhancing reliability. By focusing on these indicators, operators can significantly improve pump performance and durability.

The Impact of Temperature on Pump Lubrication Efficiency

Temperature plays a critical role in the efficiency of pump lubrication, significantly impacting both the performance of the lubricant and the operational lifespan of the pump. High temperatures can cause lubricants to degrade faster, leading to reduced viscosity and, consequently, diminished protective qualities. This degradation results in increased friction and wear between moving parts, which can ultimately lead to pump failure if not managed properly. Maintaining optimal operating temperatures is essential to ensure that lubricants can effectively perform their functions and provide the necessary protection for the pump components.

Conversely, excessively low temperatures can also hinder lubrication effectiveness. Cold conditions can cause certain lubricants to become too viscous, making it difficult for them to flow and provide adequate coverage and protection to the pump's moving parts. In both extremes of temperature, operators must carefully select the appropriate lubricant that can withstand varying thermal conditions and maintain its properties throughout the operating range. By understanding the relationship between temperature and lubrication efficiency, plant managers can implement strategies that optimize pump performance and extend the longevity of their pumping systems.

Related Posts

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China