Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

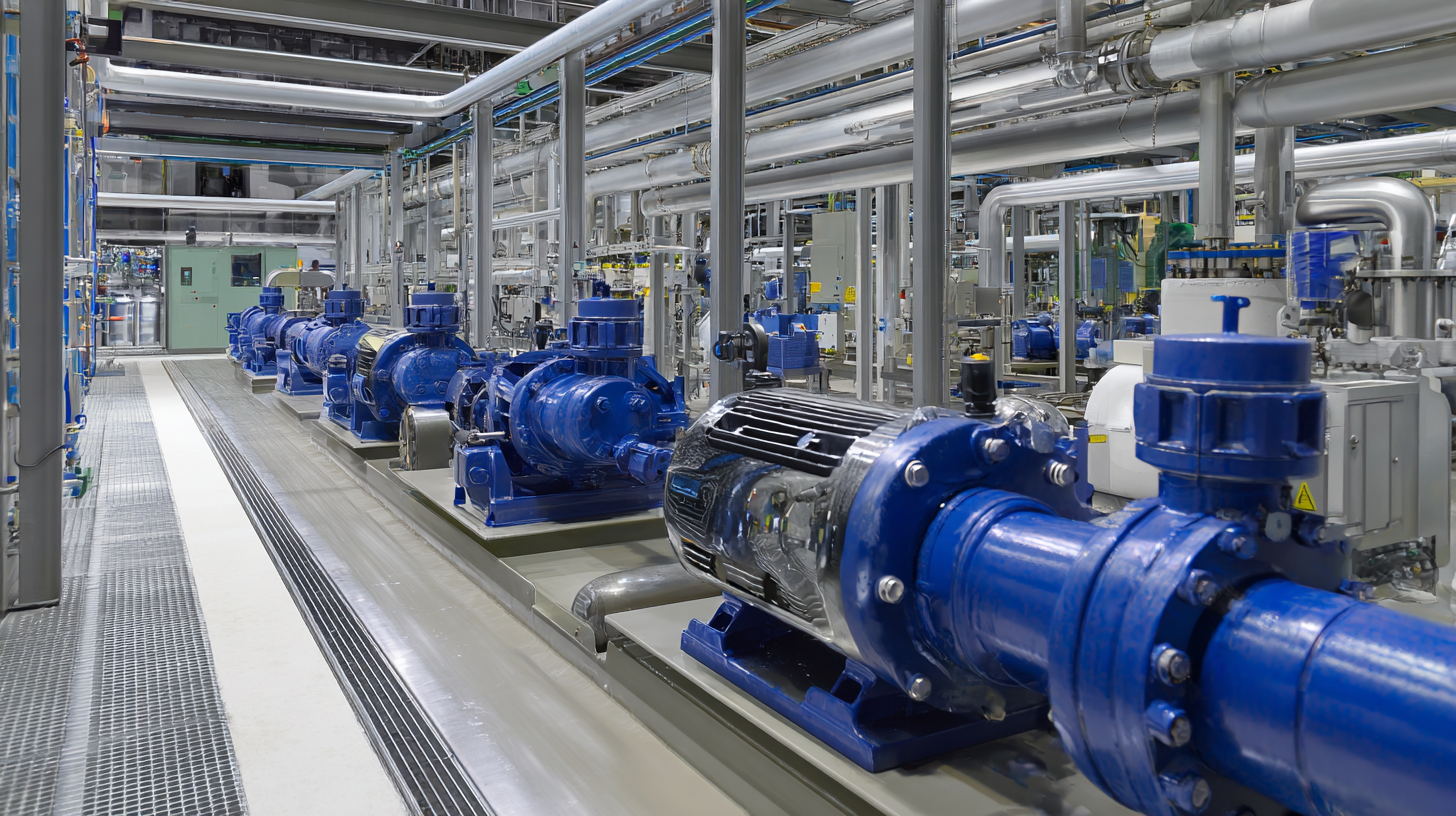

Displacement pumps play a critical role in various industrial applications, offering precise fluid management solutions that enhance operational efficiency. According to a report by the Global Market Insights, the displacement pumps market is projected to reach over $11 billion by 2026, driven by the demand for reliable and efficient fluid transfer systems across sectors such as oil and gas, chemical processing, and water treatment. These pumps are renowned for their ability to maintain a constant flow rate, which is essential for processes that require consistent fluid delivery.

Displacement pumps play a critical role in various industrial applications, offering precise fluid management solutions that enhance operational efficiency. According to a report by the Global Market Insights, the displacement pumps market is projected to reach over $11 billion by 2026, driven by the demand for reliable and efficient fluid transfer systems across sectors such as oil and gas, chemical processing, and water treatment. These pumps are renowned for their ability to maintain a constant flow rate, which is essential for processes that require consistent fluid delivery.

With advancements in pump technology and materials, manufacturers are developing more robust displacement pumps that can withstand challenging environments while improving energy efficiency. As industries strive for sustainability and cost-effectiveness, understanding the operational efficiencies of displacement pumps becomes paramount in optimizing fluid management practices and achieving greater productivity.

Understanding Displacement Pumps: Key Features and Benefits for Industry Applications

Displacement pumps play a crucial role in various industrial applications, primarily due to their unique ability to move fluids efficiently and uniformly. Key features of these pumps include their design, which allows for the precise management of flow rates and pressures. According to a report by the Equipment Manufacturers Association, displacement pumps can achieve efficiency rates up to 90% in specific applications, significantly reducing energy consumption and operational costs. This efficiency stems from their positive displacement mechanism, which ensures that the same volume of fluid is delivered with each cycle, making them ideal for handling viscous fluids and slurries commonly found in industries like oil and gas and wastewater treatment.

In addition to their impressive efficiency, displacement pumps offer several benefits that enhance their appeal for industrial use. They can operate effectively under varying pressure conditions, which is crucial for processes that demand consistent flow rates despite changes in system pressure. An analysis published by the International Pump Industry Association indicates that displacement pumps are essential in sectors such as chemical processing and pharmaceuticals, where precise fluid management is paramount. Furthermore, the durability and reliability of these pumps reduce maintenance needs, allowing companies to focus on productivity rather than equipment downtime. This combination of efficiency, consistency, and low maintenance positions displacement pumps as vital components in modern industrial fluid management systems.

Calculating Pump Efficiency: Essential Metrics for Optimal Performance

When managing fluid systems in industrial applications, the efficiency of displacement pumps is paramount. Key metrics such as pump efficiency, volumetric efficiency, and mechanical efficiency provide a comprehensive understanding of performance. According to a recent report by the Hydraulic Institute, the average efficiency of modern displacement pumps ranges from 75% to 90%, thereby significantly affecting operational costs and system productivity.

Calculating pump efficiency involves analyzing both the input power and the useful work output. Pump efficiency (η) can be defined as the ratio of the hydraulic power output to the mechanical power input. For example, if a pump has an input power of 100 kW, and the hydraulic power output is 85 kW, the efficiency is 85%. Understanding these metrics not only helps in selecting the right pump for a specific application but also facilitates optimization strategies. The American Society of Mechanical Engineers (ASME) emphasizes utilizing performance curves and efficiency ratings to evaluate and improve the efficiency of displacement pumps. Adjustments such as resizing the pump or altering operational parameters can lead to considerable energy savings and enhanced performance in industrial fluid management.

Top Tips for Selecting the Right Displacement Pump for Your Fluid Management Needs

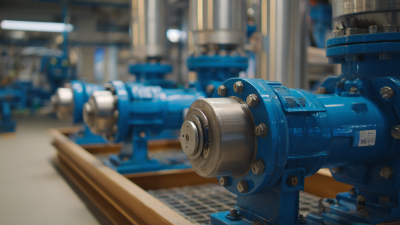

When selecting the right displacement pump for your fluid management needs, it's essential to consider several key factors to ensure optimal efficiency. First, evaluate the type of fluid you will be handling. Different displacement pumps are designed for specific viscosities and chemical compositions, so understanding the characteristics of your fluid will help narrow down your options.

Another important tip is to consider the required flow rate and pressure range for your application. Displacement pumps come in various designs, including gear, diaphragm, and peristaltic pumps, each suitable for different performance requirements. Analyzing your fluid transfer demands will guide you in selecting a pump that maintains consistent performance without frequent adjustments.

Lastly, assess the pump's maintenance requirements and overall durability. Opt for pumps that offer easy access to components for servicing and those constructed from materials that withstand corrosion and wear. Investing in a reliable displacement pump not only enhances efficiency but also prolongs the lifespan of your fluid management system, ensuring your operations run smoothly.

Best Practices for Maintenance: Ensuring Longevity and Efficiency of Displacement Pumps

Displacement pumps are vital components in various industries, providing consistent and reliable fluid management. To ensure their longevity and efficiency, regular maintenance practices are essential. According to a report by the Hydraulic Institute, pump wear can increase operational costs by up to 30% when maintenance is neglected. Regular inspections and timely replacements of worn-out parts significantly enhance performance and prevent costly downtime.

Tips for maintaining displacement pumps include regularly checking the seals and gaskets for leaks, as well as monitoring fluid viscosity and temperature. For instance, maintaining optimal temperatures can prevent fluid degradation, which is crucial for hydraulic applications. Furthermore, adhering to the manufacturer’s recommended maintenance schedule can help identify potential issues before they escalate. A study conducted by the American Society of Mechanical Engineers indicates that a systematic maintenance approach can extend pump life by up to 50%.

Another vital practice is the use of high-quality fluids tailored for specific applications. Selecting the appropriate fluid not only improves pump efficiency but also reduces wear. Regularly replacing fluids based on the operating conditions can enhance performance metrics and contribute to overall energy savings, which, according to a report by the Energy Conservation Program, can be up to 20% in some applications.

Innovative Technologies in Displacement Pump Design: Enhancing Performance and Reducing Costs

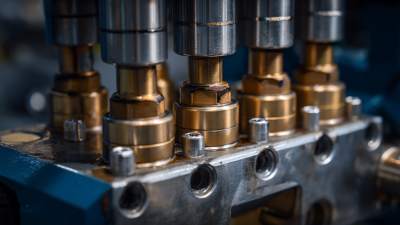

Innovative technologies in displacement pump design are revolutionizing fluid management in various industries, enhancing both performance and cost-effectiveness. One of the prominent advancements is the incorporation of smart sensor technology, which allows for real-time monitoring and adjustments. This capability not only improves operational efficiency but also extends the life of the pump by minimizing wear and tear. By employing predictive maintenance strategies, industries can significantly reduce downtime and associated costs.

Moreover, the integration of advanced materials and manufacturing techniques is contributing to more resilient and efficient displacement pumps. Lightweight materials, for instance, reduce energy consumption during operation while maintaining durability. Alongside this, 3D printing technologies enable the production of complex geometries that optimize fluid flow dynamics. These innovations lead to performance enhancements that facilitate lower operational costs and improved environmental sustainability. As industries continue to embrace these technologies, the future of displacement pumps looks promising, with increased emphasis on efficiency and eco-friendliness.

Exploring the Efficiency of Displacement Pumps

Related Posts

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity