Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

The oil pumping machine is a critical component in the petroleum industry, playing a vital role in the extraction and transportation of crude oil. Recent reports indicate that the global oil pumping machine market is projected to reach USD 3.2 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth is driven by the increasing demand for efficient extraction techniques and the deployment of advanced mechanical technologies. For instance, the adoption of electric submersible pumps (ESPs) is revolutionizing oil extraction, enhancing efficiency by up to 30% compared to traditional methods. Furthermore, the integration of IoT technology in modern oil pumping machines facilitates real-time monitoring and predictive maintenance, significantly reducing operational costs. As the industry focuses on innovation and sustainability, understanding the mechanics and advancements behind these machines becomes essential for maximizing productivity and ensuring environmental compliance.

The Evolution of Oil Pumping Technology: A Historical Perspective

The evolution of oil pumping technology has been dramatic, tracing its roots back to the early days of the oil industry in the mid-19th century. The first mechanical pumps allowed for the extraction of oil from deep underground, significantly increasing production capabilities. According to the U.S. Energy Information Administration, oil production in the United States grew from approximately 2 million barrels per year in 1860 to over 10 billion barrels by 1970, largely due to advancements in pumping technology. These early pumps paved the way for innovations, such as the introduction of electrical submersible pumps (ESPs) in the 1920s, which further enhanced the efficiency of oil extraction.

As we moved into the 21st century, the need for more efficient and sustainable technology has driven further innovations in oil pumping machines. Recent studies indicate that the use of advanced artificial lift techniques has improved oil recovery rates by up to 20%. Moreover, with the increasing focus on reducing environmental footprints, many companies are investing in automated and smart pumping systems that optimize energy use and reduce operational costs. Industry reports appraising these advancements suggest that the global market for oil pumping technologies is poised to reach $10 billion by 2026, underscoring the ongoing commitment to innovation in this essential sector.

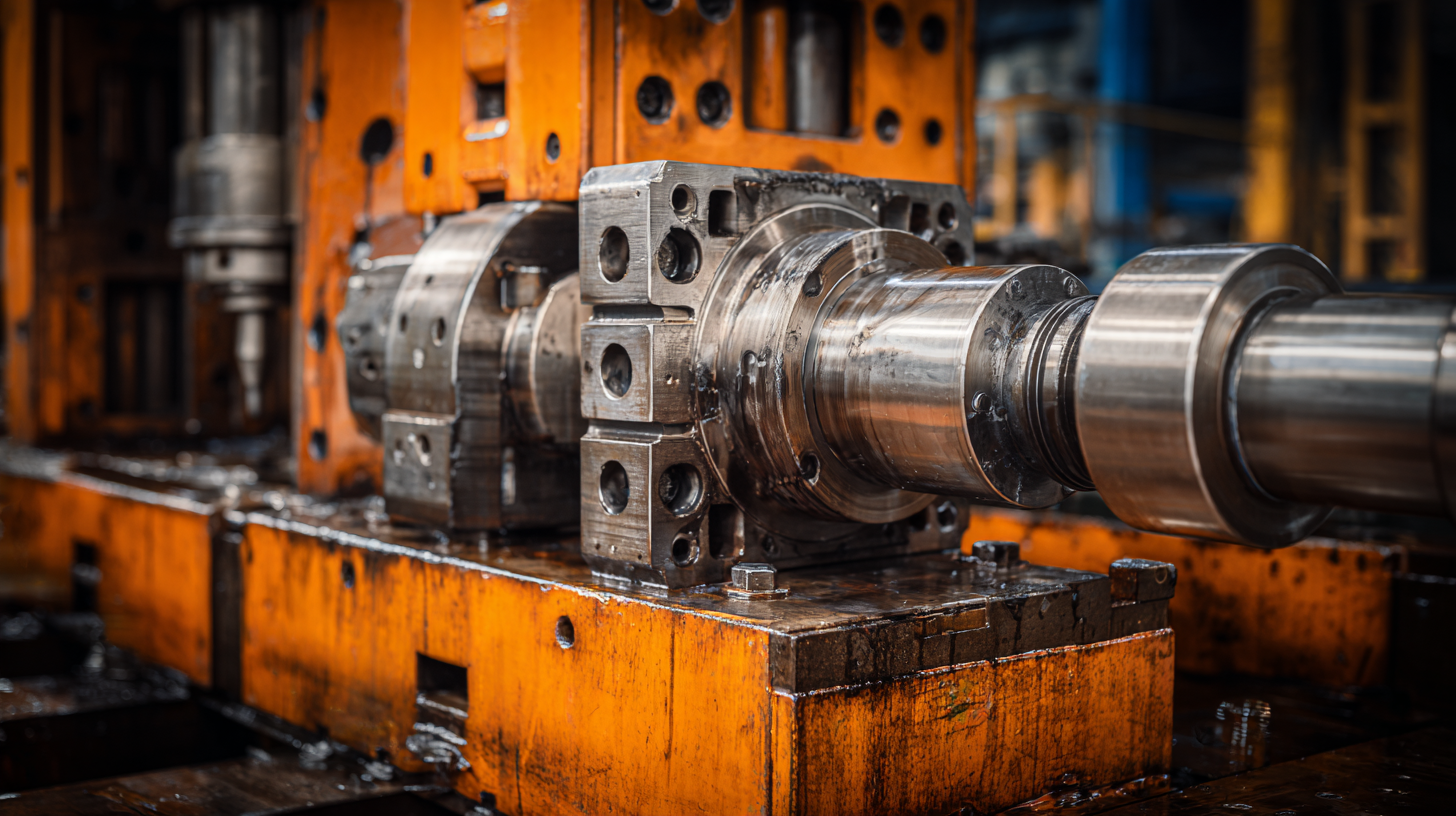

Key Components of Modern Oil Pumping Machines and Their Functions

Modern oil pumping machines are intricate systems designed to enhance efficiency and innovation in the oil extraction process. At the core of these machines are several key components, each playing a vital role in their operation. One of the primary components is the pump itself, which can be of various types, including centrifugal and positive displacement pumps. These pumps are engineered to handle large volumes of oil while maintaining optimal pressure levels, ensuring a steady flow to processing facilities.

Another essential component is the drive system, which powers the pump. This may include electric motors or hydraulic systems that convert different forms of energy into mechanical power. Coupled with sensors and control systems, the drive system allows for precise monitoring and adjustments, enhancing the machine's responsiveness to varying operational demands. Additionally, safety devices are integrated into modern oil pumping machines to prevent overpressure and overheating, ensuring both operational efficiency and worker safety. Overall, the synergy of these components contributes significantly to the effectiveness of modern oil pumping technologies.

Innovative Features Enhancing Efficiency in Oil Extraction Processes

Modern oil pumping machines are at the forefront of enhancing efficiency in oil extraction processes, with innovative features that significantly improve output. As underwater oil reserves have become increasingly vital, accounting for a substantial percentage of global oil and gas supply, the design and materials used in these machines are evolving. Recent advancements in materials science have contributed to this evolution, enabling the development of new technologies that address challenges such as hydrate formation in deep-water environments.

Moreover, the integration of high-performance materials into oil pumping systems has led to breakthroughs in durability and efficiency. These materials not only improve the machines' operational lifespan but also enhance their adaptability to complex underwater conditions. This dual focus on innovative machinery and advanced materials is essential for the oil industry, allowing it to meet the growing demand for oil while navigating the challenges posed by deep-water exploration. The synergy between cutting-edge technologies and new material applications is driving the next wave of innovation in oil extraction processes.

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

| Feature | Description | Efficiency Gain (%) | Innovation Type |

|---|---|---|---|

| Variable Frequency Drive (VFD) | Optimizes motor speed based on demand | 15 | Automation |

| Smart Sensors | Monitor pressure and flow rates in real-time | 20 | IoT |

| Recycling Systems | Recovers and reuses drilling fluids | 30 | Resource Recovery |

| Enhanced Fluid Dynamics | Improved design for better flow efficiency | 25 | Engineering |

| Predictive Maintenance | Uses analytics to predict equipment failures | 10 | Data Analytics |

Digital Transformation in Oil Pumping: Automation and Remote Monitoring

The digital transformation of oil pumping operations has ushered in a new era of efficiency and effectiveness through the integration of automation and remote monitoring technologies. Automation minimizes human intervention in the pumping process, allowing for precision control and eliminating the potential for human error. Advanced algorithms can optimize pumping schedules and streamline operations, leading to significant cost reductions and improved resource management. This shift not only enhances productivity but also ensures that environmental regulations are met more consistently.

Remote monitoring systems play a crucial role in this transformation, enabling operators to track the performance of pumping machines in real-time. With the use of Internet of Things (IoT) sensors, data is gathered on various parameters such as pressure, flow rates, and equipment health. This data can be analyzed to predict maintenance needs, reducing downtime and preemptively addressing potential issues before they escalate. Furthermore, the ability to monitor systems remotely empowers companies to operate across vast distances, making it easier to manage multiple sites efficiently. As the industry embraces these digital advancements, the future of oil pumping looks not only more efficient but also more sustainable.

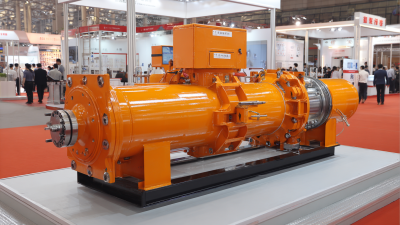

Future Trends: Sustainability and Smart Technology in Oil Pumping Systems

The oil and gas pumping industry is undergoing a significant transformation driven by sustainability and smart technology. As market demands evolve, innovative solutions are being implemented to enhance efficiency and reduce environmental impact. The global market for oil and gas pumps is expected to experience steady growth, reaching an estimated value of $125.7 billion by 2032, reflecting a compound annual growth rate of 4.54%. This growth is largely attributed to the rise of automated systems and intelligent technologies designed to optimize pumping processes.

Tips: To stay ahead in the industry, companies should invest in R&D for smart pumping technologies that utilize real-time data monitoring and advanced process controls. Embracing automation not only improves operational efficiency but also aids in achieving sustainability goals.

The recent Sustainable Development Forum highlighted collaborative innovation as a means to a sustainable future, engaging numerous leading global enterprises to discuss the petrochemical sector's evolution. By integrating innovative practices and smart technologies, the oil pumping sector can align itself with future sustainability trends, ensuring a competitive edge in an increasingly eco-conscious market.

Modern Oil Pumping Machines Efficiency and Innovation

Related Posts

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

How to Choose the Right Screw Pump for Your Industrial Needs