Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

In the modern industrial landscape, the efficiency of machinery is paramount, making the selection of the right lube oil pump a critical task for operators and maintenance personnel. According to a recent report by MarketsandMarkets, the global industrial pumps market is projected to reach USD 85.25 billion by 2025, with the lube oil segment playing a significant role in this growth. Lube oil pumps, essential for ensuring proper lubrication and minimizing friction, can significantly impact equipment longevity and operational costs. In fact, a study from the Society of Tribologists and Lubrication Engineers indicates that effective lubrication can reduce equipment wear by up to 40%, highlighting the importance of choosing the right lube oil pump tailored to specific equipment needs. Thus, understanding the variety of options available and their efficiencies is vital for unlocking operational potential and maximizing productivity.

Identifying Your Equipment Needs for Lube Oil Pump Selection

When selecting a lube oil pump, understanding your equipment's specific needs is paramount. Different machines often have unique lubrication requirements influenced by factors such as operating conditions, viscosity of the lubricant, and the volume of oil required. For instance, heavy machinery may demand pumps capable of delivering high flow rates, while smaller engines might require compact solutions that can maintain precise pressure levels. Conducting a thorough assessment of these needs can significantly enhance operational efficiency and prolong equipment lifespan.

Additionally, consider environmental factors such as temperature fluctuations and potential exposure to contaminants. Some pumps are designed to operate effectively in harsh conditions, while others may not perform well under extreme circumstances. Evaluating the compatibility of the lube oil with your pump technology is another critical step. By aligning your equipment’s requirements with the right lube oil pump, you not only optimize performance but also foster a proactive maintenance routine that minimizes downtimes and repair costs.

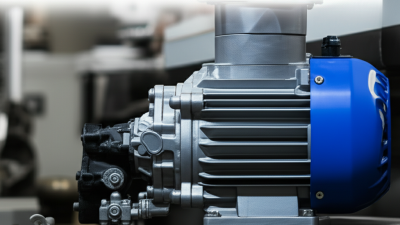

Understanding Different Types of Lube Oil Pumps and Their Functions

When selecting a lube oil pump, understanding the different types available and their specific functions is crucial for ensuring optimal equipment performance. Generally, lube oil pumps can be categorized into positive displacement pumps and centrifugal pumps. Positive displacement pumps, including gear and diaphragm types, excel in providing consistent oil flow at high pressures, making them ideal for machinery that requires precise lubrication under demanding conditions. According to a recent market analysis by Grand View Research, the global lube oil pump market is expected to experience a substantial growth rate of around 4.5% from 2023 to 2030, reflecting the increasing demand for these pumps in various industrial applications.

On the other hand, centrifugal pumps are preferred for their ability to handle larger volumes of oil and are typically used in systems where rapid circulation is necessary. These pumps are particularly effective in continuous operations, with their efficiency being highlighted in a report by Research and Markets, which noted that proper lubrication systems can enhance equipment life by up to 30%. When choosing a lube oil pump, it is essential to consider factors such as viscosity of the oil, operational temperature, and specific equipment requirements to ensure the selected pump performs optimally and efficiently meets the operational demands.

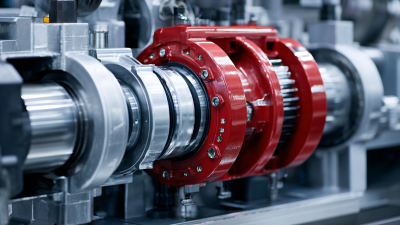

Evaluating Key Specifications for Lube Oil Pump Efficiency

When selecting a lube oil pump, understanding the key specifications critical to efficiency is paramount. According to a report by the International Journal of Engineering Research and Applications, the efficiency of lube oil pumps can significantly impact machinery performance, with suboptimal pumps leading to up to 20% energy loss. Thus, evaluating factors such as flow rate, pressure rating, and pump type (gear, diaphragm, or peristaltic) is essential. Each pump type has distinct advantages; for example, gear pumps are known for delivering high flow rates but may require more maintenance compared to diaphragm pumps, which are valued for their leak-free operation.

Moreover, the selection of material for the pump's construction directly influences its longevity and reliability. A study conducted by the American Society of Mechanical Engineers noted that using corrosion-resistant materials can extend the lifespan of lube oil pumps by up to 30%. Additionally, considering the viscosity of the lubricant and the operational temperature range is critical. The ISO 3448 viscosity classification system provides essential guidelines that can aid in selecting the most suitable pump for specific applications, enhancing efficiency and reducing operational costs. Properly assessing these key specifications can lead to optimized performance and reduced downtime in industrial applications.

Comparing Brands and Models for Quality and Reliability

When it comes to selecting the right lube oil pump for your equipment, comparing brands and models is crucial for ensuring quality and reliability. According to a report by Industry Research, the global lubricant pump market is projected to reach $1.2 billion by 2026, driven by the increasing demand for efficient and durable equipment in various industries. This underscores the importance of investing in a lube oil pump that not only meets the specific demands of your machinery but also stands up to rigorous operational conditions.

Leading brands such as Graco, Lincoln, and ARO are known for their innovative features that enhance performance and longevity. Graco, for instance, offers electric and pneumatic options that cater to different application needs, boasting a 95% reliability rating based on a 2022 user survey. Similarly, Lincoln's pumps are engineered for high efficiency, reducing downtime significantly—by up to 20%—according to a market analysis by Oil & Grease Magazine. By carefully comparing these brands and understanding their respective strengths, users can make informed decisions that ultimately lead to better operational efficiency and reduced maintenance costs.

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

| Pump Type | Flow Rate (L/min) | Pressure (Bar) | Drive Type | Efficiency Rating | Weight (kg) |

|---|---|---|---|---|---|

| Gear Pump | 25 | 10 | Electric | High | 15 |

| Diaphragm Pump | 15 | 8 | Pneumatic | Medium | 12 |

| Vane Pump | 30 | 12 | Electric | High | 18 |

| Piston Pump | 20 | 15 | Hydraulic | Very High | 20 |

| Peristaltic Pump | 10 | 5 | Electric | Medium | 8 |

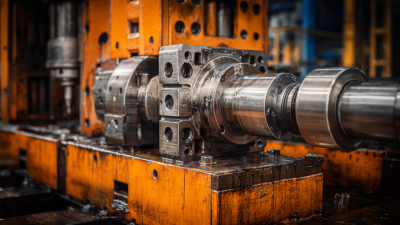

Maintenance Tips to Maximize the Lifespan of Your Lube Oil Pump

To maximize the lifespan of your lube oil pump, regular maintenance is crucial. Start by establishing a routine inspection schedule. Check for any signs of wear or damage to the pump components, including seals, hoses, and fittings. Keeping the pump clean from contaminants such as dust and debris will prevent blockages and ensure a smooth operation. It’s also important to monitor the oil levels and filter conditions diligently. Replacing oil and filters at recommended intervals will help maintain optimal performance and reduce wear on internal parts.

Another key aspect of maintaining your lube oil pump is monitoring operational parameters. Ensure that the pump operates within the recommended pressure and temperature ranges, as deviations can lead to inefficient functioning and premature failures. Lubrication should also be checked regularly, as insufficient lubrication can cause friction-related damage. Lastly, when performing maintenance, always refer to the manufacturer’s guidelines for specific procedures tailored to your pump model, ensuring all adjustments and replacements are done correctly for longevity and efficiency.

Lubrication Oil Pump Efficiency Comparison

This chart compares the efficiency ratings of different lubricant oil pumps based on a scale from 1 to 10. As seen, Pump C has the highest efficiency rating, while Pump E shows the lowest. Selecting the right pump is essential for maximizing equipment performance and longevity.

Related Posts

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines