How to Choose the Right Screw Pumps for Your Needs?

Choosing the right screw pumps for your application is crucial. Industry expert Dr. John Matthews once said, "Selecting the correct screw pump can save time and costs significantly." This statement highlights the importance of making informed decisions.

Screw pumps are designed for various fluids, from water to viscous materials. Understanding your specific needs is essential. Consider factors like flow rate, pressure requirements, and fluid characteristics. Each application has different demands, and a poor selection can lead to inefficiencies.

Take time to research. Look into different models and materials. Evaluate how specific designs impact performance. Not all screw pumps are the same. Ensure that your choice aligns with your operational goals. As with any technology, there are no perfect solutions; you must find the best fit for your situation.

Understanding the Basics of Screw Pumps and Their Applications

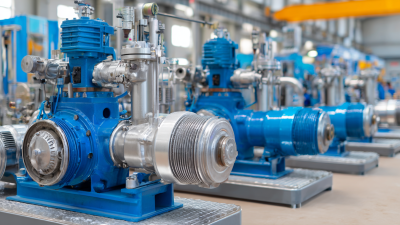

Screw pumps are widely used in various industries. They excel in transporting thick liquids and slurries. Their design features interlocking screws, which provide a smooth flow. This makes them suitable for food processing, chemicals, and wastewater. However, selecting the right screw pump can be challenging.

Consider your specific application before choosing a pump. Analyze the fluid characteristics, such as viscosity and temperature. These factors directly impact pump performance. Some pumps may not handle certain materials well, leading to premature wear. Smaller projects might benefit from a more compact model, while larger operations could need heavy-duty pumps.

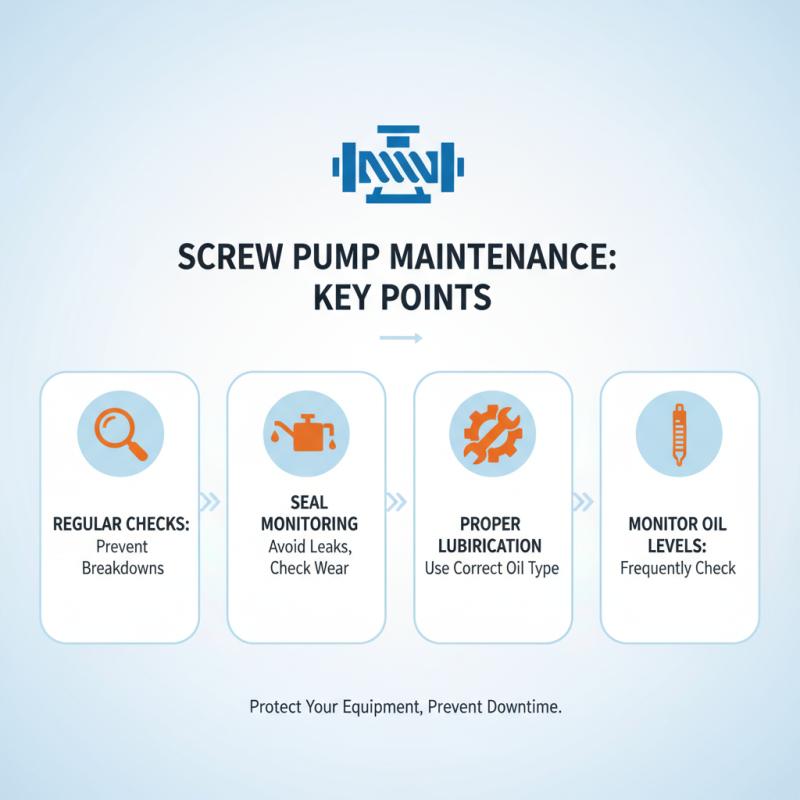

Maintenance is another critical aspect. Regular checks can prevent breakdowns and extend the pump's life. Think about the available space for installation and the ease of access for repairs. Sometimes, users overlook these dimensions, leading to future inconveniences. Balancing performance, size, and maintenance will help you make an informed decision.

How to Choose the Right Screw Pumps for Your Needs?

| Pump Type | Flow Rate (m³/h) | Pressure Range (bar) | Viscosity Limit (cP) | Optimal Applications |

|---|---|---|---|---|

| Single Screw Pump | 5 - 150 | 1 - 8 | 1 - 1000 | Food, Chemicals |

| Twin Screw Pump | 10 - 200 | 2 - 10 | 1 - 5000 | Petroleum, Polymer |

| Triple Screw Pump | 20 - 300 | 3 - 12 | 1 - 10000 | Lube Oil, Fuel |

| Progressive Cavity Pump | 5 - 100 | 0.5 - 8 | 1 - 300000 | Waste Sludge, Food Products |

Factors to Consider When Selecting a Screw Pump for Your System

Choosing the right screw pump is crucial for efficient operation. There are various factors to consider for your specific application. The viscosity of the fluid is one of the primary concerns. Higher viscosity fluids require pumps designed for such conditions. You might think all pumps can handle everything, but that’s a common misconception.

Another factor is the flow rate. You need to estimate the required flow rate accurately. If underestimated, you may face issues with insufficient output. If overestimated, it can lead to excessive energy consumption. A balance is essential. The operating pressure of your system also plays a vital role. Not all pumps can deal with high pressures, and selecting the wrong one may cause failures.

Additionally, consider the materials used in the pump’s construction. Corrosive fluids need pumps made from resistant materials. If you ignore material compatibility, you could end up with a pump that deteriorates quickly. Availability of spare parts and service support cannot be overlooked either. Inadequate support can lead to prolonged downtimes. Taking the time to assess these factors can help you avoid costly mistakes.

Comparison of Screw Pump Efficiency Based on Application

This bar chart illustrates the efficiency of screw pumps in various applications, highlighting key factors to consider when selecting a screw pump for your system. Each application demonstrates varying efficiency levels, essential for determining the best pump for your needs.

Comparing Different Types of Screw Pumps for Specific Needs

When selecting a screw pump, it's essential to consider the specific needs of your application. Screw pumps come in various designs, each tailored for different fluids and operating conditions. For instance, a single-screw pump works well for low-viscosity substances, while a twin-screw pump is better suited for handling high-viscosity liquids. Understanding these distinctions is critical for optimal performance.

Different industries require different pumping solutions. In the oil and gas industry, for example, twin-screw pumps are often preferred for their efficiency and ability to handle challenging fluids. Conversely, in the food and beverage sector, positive displacement screw pumps are popular for their hygienic properties. However, matching the pump type with the application is not always straightforward. Decisions can be clouded by brand influence or costs, leading to potential pitfalls.

Moreover, installation and maintenance play key roles in longevity and efficiency. A poorly installed pump may underperform, resulting in downtime or increased costs. Routine maintenance practices may also vary based on pump type. Therefore, investing time in understanding these dynamics can yield significant benefits. Selecting the right screw pump requires careful analysis and a willingness to adapt based on specific needs.

Maintenance and Performance Factors for Long-lasting Screw Pumps

When it comes to screw pumps, maintenance is key. Regular checks can prevent major breakdowns. Pay attention to the seals; they wear out over time. If a seal fails, it can lead to leaks. This issue can damage both the pump and the surrounding area. Proper lubrication is also essential. Use the right type of oil, and monitor levels frequently.

Performance factors play a significant role in durability. The pump should be sized correctly for the application. Oversized pumps may run inefficiently. Under-sized pumps can lead to overworking, which causes early failures. Temperature and pressure conditions also matter. Extreme conditions stress the material, leading to cracks.

Operational habits impact longevity. Train staff to operate pumps correctly. Misuse can lead to unnecessary wear and tear. Keeping a log of performance can identify patterns. If something seems off, investigate it. Ignoring small issues can escalate them into larger problems. Make sure to review maintenance logs regularly.

Cost vs. Efficiency: Making the Right Investment in Screw Pumps

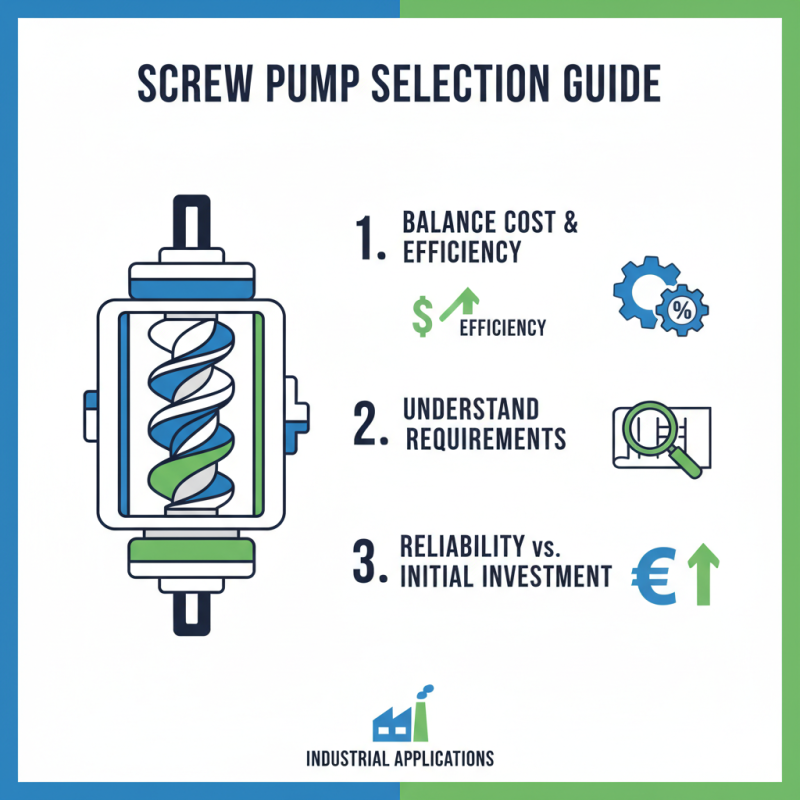

Choosing screw pumps involves balancing cost and efficiency. Understanding your requirements is vital. Many industries use screw pumps for their reliability. However, the initial investment can be significant.

According to the Fluid Pumps Market Report, screw pumps can be 20% more efficient than traditional pumps. This efficiency often translates to lower energy costs over time. A study from the American Society of Mechanical Engineers highlighted that maintenance costs can be higher for less efficient systems. This is an important consideration when evaluating long-term costs.

Investing in high-quality screw pumps may seem costly upfront. Yet, their durability often leads to fewer replacements. The lifespan of a screw pump can reach over 20 years. But, if you choose a cheaper model, unexpected failures may arise. In some cases, lower efficiency models can lead to 30% more energy usage. This can significantly increase operational costs. Always analyze total cost of ownership before making a decision. Balancing initial costs against lifetime savings is essential.

Related Posts

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

Understanding the Benefits of Screw Pumps in Modern Industrial Applications

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

10 Best Screw Pumps for Efficient Fluids Management in 2026?

-

Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer