How to Choose the Right Screw Pump for Your Industrial Needs

When it comes to selecting the appropriate equipment for industrial applications, the importance of choosing the right screw pumps cannot be overstated. These versatile and efficient pumps are designed to handle a variety of fluids, ranging from low-viscosity liquids to more challenging slurries and high-viscosity substances. However, with the many models and configurations available on the market, making an informed decision can be daunting. This guide aims to simplify the selection process by highlighting key factors to consider, such as flow rate requirements, fluid properties, and operational conditions. By understanding the specific needs of your application and comparing the features of different screw pumps, you can ensure optimal performance, reliability, and cost-efficiency in your industrial processes.

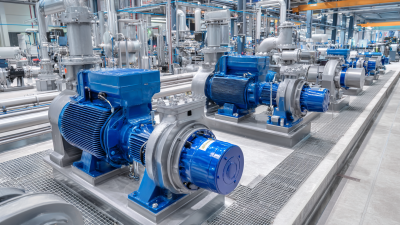

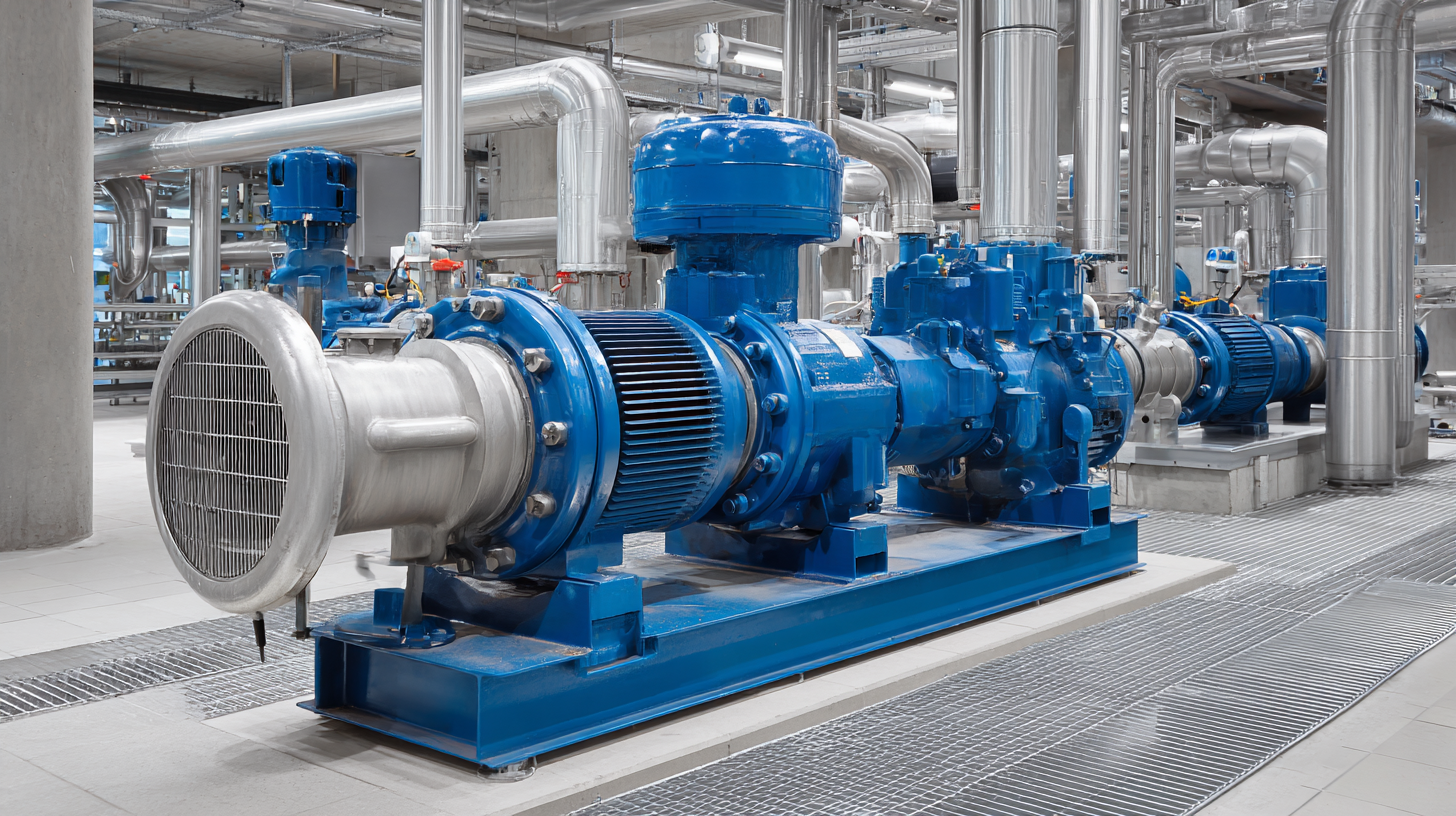

Understanding Different Types of Screw Pumps for Industrial Applications

Choosing the right screw pump for industrial applications requires a thorough understanding of the different types available and their respective functionalities. Screw pumps are renowned for their efficiency in transferring viscous fluids, making them ideal for industries like petrochemicals, wastewater treatment, and food processing. According to a recent market research report by MarketsandMarkets, the global screw pump market is projected to reach $2.09 billion by 2026, highlighting their growing adoption across various sectors.

There are primarily two types of screw pumps: single-screw and twin-screw pumps. Single-screw pumps, often referred to as progressive cavity pumps, excel in handling non-homogeneous fluids, providing a smooth and continuous flow. They are particularly effective for applications involving slurries and polymers. Conversely, twin-screw pumps are designed to manage higher flow rates and are typically employed in situations requiring precise metering of viscous liquids, such as lubricants and adhesives. A report from Research and Markets indicates that twin-screw pumps hold a significant market share due to their versatility in handling diverse fluids, alongside their ability to maintain a high level of efficiency and low shear rate during operation.

There are primarily two types of screw pumps: single-screw and twin-screw pumps. Single-screw pumps, often referred to as progressive cavity pumps, excel in handling non-homogeneous fluids, providing a smooth and continuous flow. They are particularly effective for applications involving slurries and polymers. Conversely, twin-screw pumps are designed to manage higher flow rates and are typically employed in situations requiring precise metering of viscous liquids, such as lubricants and adhesives. A report from Research and Markets indicates that twin-screw pumps hold a significant market share due to their versatility in handling diverse fluids, alongside their ability to maintain a high level of efficiency and low shear rate during operation.

Understanding these distinctions is crucial for industrial decision-makers aiming to enhance operational efficiency and equipment longevity. When selecting a screw pump, consider the specifics of the application, including fluid characteristics, desired flow rate, and operational conditions to ensure optimal performance.

Key Performance Metrics: Flow Rate, Viscosity, and Temperature Compatibility

When choosing the right screw pump for industrial applications, three key performance metrics should be carefully evaluated: flow rate, viscosity, and temperature compatibility. Flow rate, typically measured in liters per minute (L/min), is crucial as it determines the volume of fluid a pump can handle efficiently. For instance, recent studies suggest that optimizing flow rates can significantly enhance the efficiency of heat transfer systems, particularly in refrigeration contexts.

Viscosity also plays a vital role, especially in industries dealing with high-viscosity fluids. The melt viscosity, which is a critical quality indicator, can greatly affect the performance of pumps in processes like polymer extrusion. Leveraging machine learning techniques to predict melt viscosity has shown promising outcomes, making it easier to select pumps that maintain the desired performance standards under varying conditions.

Temperature compatibility is essential when operating in extreme environments. The development of pumping systems that can withstand ultra-high temperatures, similar to those found in deep oil and gas reservoirs, is increasingly important. Selecting a screw pump with suitable materials and design can ensure reliable operation even under challenging thermal conditions.

**Tips:**

1. Ensure your pump is rated for the viscosity range of your fluids, optimizing productivity and longevity.

2. Regularly monitor the operational temperature; choosing the right materials can prevent performance degradation.

3. Assess flow rate requirements based on system demands, aiming for peak efficiency while eliminating cavitation risks.

Material Selection: Evaluating Corrosion Resistance and Durability for Long-term Use

When selecting a screw pump for industrial applications, one of the primary considerations should be the material selection, particularly its corrosion resistance and durability. Industries that handle corrosive materials, such as chemicals and wastewater, require pumps made from highly resilient materials. According to a report by the Industrial Pump Market, over 30% of pump failures can be attributed to material degradation caused by corrosion. This emphasizes the importance of choosing the right materials to ensure not only functionality but also longevity of the equipment.

Stainless steel is often a go-to choice for many applications due to its excellent resistance to rust and corrosion. However, for extremely aggressive fluids, options like duplex and super duplex stainless steels can provide enhanced performance. These materials can withstand higher levels of pitting and stress corrosion cracking. The Global Corrosion Resistance Materials Market Report indicates that the demand for materials that can endure harsh environmental conditions is expected to grow by 4.5% annually, demonstrating the critical need for durability in pump systems. Understanding these material properties is essential for ensuring a screw pump operates efficiently over its intended lifespan while minimizing maintenance costs and downtime.

Cost Analysis: Total Cost of Ownership vs. Initial Investment in Screw Pumps

When evaluating screw pumps for industrial applications, understanding the total cost of ownership (TCO) is essential, particularly in relation to the initial investment. According to a recent report by the National Pump Manufacturers Association, while the upfront cost of screw pumps often exceeds that of centrifugal pumps by approximately 20-30%, the long-term savings in maintenance and operational efficiency can be significant. TCO analysis reveals that screw pumps may reduce overall maintenance costs by up to 40% due to their robust design and lower wear rates, making them a more strategic investment over time.

Moreover, the energy efficiency of screw pumps cannot be overlooked. A study published by the Energy Efficiency Industrial Program indicates that these pumps can deliver a 10-15% improvement in energy consumption compared to other pumping technologies, further enhancing their economic appeal. When factoring in reduced downtime and enhanced performance life, the initial investment in screw pumps can lead to a more favorable TCO, positioning them as a sound choice for industries focused on cost-effective and efficient fluid handling solutions.

Manufacturer Reputation and Industry Certifications: Ensuring Quality and Reliability

When selecting a screw pump for industrial applications, the reputation of the manufacturer plays a vital role in ensuring quality and reliability. Established manufacturers with a long-standing history in the industry often have a track record of producing durable and efficient screw pumps. Their experience can be indicative of not only the quality of their products but also their ability to provide effective customer support and after-sales services. Researching online reviews, testimonials, and case studies can help gauge a manufacturer’s reliability and customer satisfaction.

In addition to reputation, industry certifications should also be a key consideration. Certifications from recognized organizations demonstrate that the manufacturer adheres to strict quality standards and regulations. These certifications, such as ISO 9001 or API standards, can guide buyers in evaluating the performance and safety of the pumps. A certified manufacturer is more likely to implement rigorous testing and quality control processes, ensuring that the screw pumps will operate efficiently and reliably in various industrial environments. Therefore, it is crucial to verify these credentials before making a purchase to ensure a sound investment.

How to Choose the Right Screw Pump for Your Industrial Needs

| Dimension | Value | Importance |

|---|---|---|

| Manufacturer Reputation | High | Ensures trust and reliability |

| Industry Certifications | ISO 9001, API 676 | Verifies quality management systems |

| Customer Reviews | Positive | Reflects user satisfaction |

| Technical Support | Available 24/7 | Critical for operational efficiency |

| Warranty Period | 5 Years | Provides assurance and protection |

| Customization Options | Yes | Tailors to specific needs |