How to Choose the Right Cavity Pump for Your Application?

Choosing the right cavity pump is crucial for a successful application. According to Dr. Emily Collins, a leading expert in fluid dynamics, "Understanding your system’s needs vastly improves your cavity pump selection." Cavity pumps operate differently than other pumps, making knowledge about their functionality essential.

When selecting a cavity pump, consider factors like fluid characteristics, temperature, and viscosity. A wrong choice can lead to inefficiency or even pump failure. Dr. Collins emphasizes, “Each application has unique demands.” This aspect challenges many users who may not fully understand their operational environment.

Moreover, potential buyers often overlook maintenance requirements. Regular upkeep is vital for optimal performance. A well-chosen cavity pump can save time and reduce costs. However, it requires thoughtful consideration to ensure it meets the specific needs of your application.

Understanding Cavity Pumps and Their Applications

Cavity pumps are versatile tools used in many industries. They excel in transferring viscous fluids and slurries. These pumps operate using a unique rotor and stator mechanism. This design allows for consistent flow and reduces pulsation. Cavity pumps can handle a variety of applications, from food processing to wastewater management.

When selecting a cavity pump, consider the fluid characteristics. Analyze viscosity, temperature, and chemical composition. These factors play a crucial role in pump performance. Not all cavity pumps are suitable for every application. Improper selection can lead to inefficiency or breakdowns, causing costly downtime.

**Tip:** Always consult with an expert before making a choice. They can help evaluate your specific needs.

Additionally, think about maintenance requirements. Some pumps require more frequent servicing than others. A low-maintenance option may seem attractive, but can it handle your workload?

**Tip:** Keep a maintenance log. Recording service history helps you avoid unexpected failures. Regular checks ensure your pump operates smoothly.

Choosing the right cavity pump requires careful thought. Mistakes can lead to significant issues down the road. Reflect on your options to ensure the best fit for your application.

Key Factors to Consider When Choosing a Cavity Pump

Choosing the right cavity pump for your needs can be a complex decision. One key factor is the fluid type. Different fluids have varying viscosities and corrosive properties. For example, viscous fluids require pumps that can handle thicker materials without clogging. On the other hand, corrosive fluids demand materials that resist chemical reactions. Understanding your fluid’s characteristics is essential.

Another crucial consideration is the pump's flow rate. This dictates how quickly your system can operate. A pump with an insufficient flow rate may hinder productivity. Ideally, select a pump that meets your operational demands without being over or underpowered. Additionally, consider the application's pressure requirements. This affects not only the selection but also the longevity of the pump.

It’s also essential to think about maintenance. Some pumps require more upkeep than others. A pump that is hard to maintain may lead to unforeseen downtimes. As a result, it’s important to weigh initial costs against long-term maintenance. Balancing efficiency with practicality often involves trial and error. Each application may present unique challenges that need to be addressed.

Choosing the Right Cavity Pump: Key Factors

This chart illustrates various key factors to consider when selecting a cavity pump, along with their importance ratings based on typical application needs.

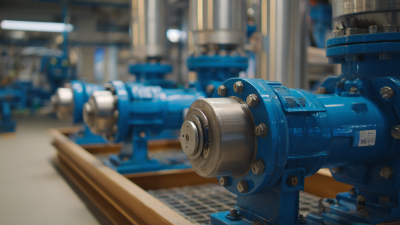

Comparing Different Types of Cavity Pumps

When selecting a cavity pump, understanding the different types is crucial. Cavity pumps can be categorized into progressive cavity pumps, twin screw pumps, and rotary lobe pumps. Each type has unique advantages depending on the application. For example, progressive cavity pumps handle high-viscosity fluids effectively, making them ideal for the oil and gas industry. In contrast, rotary lobe pumps excel in applications that require gentle handling of shear-sensitive materials, such as food processing.

A report from the Hydraulic Institute indicates that up to 30% of pumping issues arise from the selection of the wrong pump type. Misjudging the power required can lead to inefficiencies and operational failures. Cavity pumps can sometimes be overdesigned, resulting in higher energy costs. For instance, progressive cavity pumps can operate efficiently at lower speeds, which impacts performance and energy use.

Additionally, considering the material compatibility is vital. For aggressive fluids, the pump's materials must withstand corrosion. Yet, many users overlook this aspect, leading to frequent maintenance and replacements. In harsh environments, selecting the right shaft seals becomes essential to avoid leaks. Users often need to reevaluate their choices to ensure long-term operational efficiency and reliability.

Assessing Pump Performance and Specifications

When selecting a cavity pump, performance and specifications are crucial. Start by understanding the fluid characteristics. Consider viscosity and temperature. These factors influence pump efficiency. A pump must handle both without excessive wear. Ensure it maintains optimal flow rates. Poor flow can lead to operational issues.

Next, look at the pump's design and materials. Corrosion-resistant materials may be necessary for certain fluids. This choice can affect the lifespan of the pump. A mismatch here could result in frequent replacements. Evaluate the pump's energy efficiency as well. Higher efficiency can lead to cost savings over time.

Lastly, think about the application environment. Will the pump be used in a stable setting or one with frequent changes? Accessibility for maintenance is vital. Pumps placed in hard-to-reach areas pose challenges. Monitor performance regularly to catch any decline early. Sometimes, a pump that works well today might not suit future needs. Regular reassessment is key to long-term success.

Maintenance and Care for Cavity Pumps

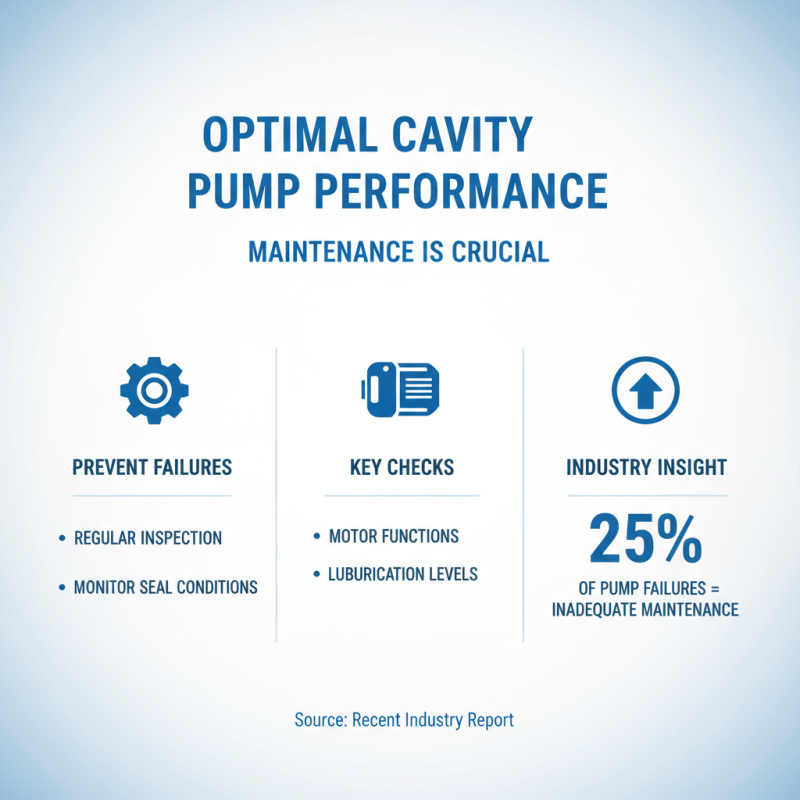

Maintaining cavity pumps is crucial for optimal performance. Regular inspection can prevent failures. It's recommended to monitor seal conditions, motor functions, and lubrication levels. A recent industry report showed that 25% of pump failures stem from inadequate maintenance.

Cleaning is also essential. Dirt can accumulate in the pump, affecting efficiency. Operators should schedule cleaning every three months. Many overlook this step. A clean pump can increase lifespan significantly. Reports indicate a well-maintained pump operates 15-20% more efficiently.

Operators should also pay attention to vibration analysis. Unusual vibrations can be an early warning sign. Research indicates that addressing these issues early can reduce costly repairs. Emphasizing timely maintenance checks leads to fewer breakdowns. Effective maintenance ultimately saves time and money.

Related Posts

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

Top Benefits of Double Screw Pumps for Efficient Fluid Handling

-

High Pressure Screw Pump Tips for Optimal Performance and Maintenance

-

Top Cavity Pumps for 2025 Applications and Benefits You Should Know

-

2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs