How to Choose the Right Pumps for Oil Based on Your Specific Needs

Choosing the right pumps for oil is essential for ensuring efficient and effective operations in various sectors, including industrial, commercial, and even residential applications.

With a plethora of options available in the market, it can be challenging to determine which pump type best suits your specific needs.

Factors such as the viscosity of the oil, the temperature at which it will be transferred, and the required flow rate must all be carefully considered.

Additionally, understanding the different types of pumps for oil—such as centrifugal, positive displacement, and diaphragm pumps—can help narrow down your choice.

This guide aims to shed light on the critical factors you should consider when selecting pumps for oil to optimize performance and minimize costs, ensuring that you find the perfect match for your unique applications and operational challenges.

Choosing the right pumps for oil is essential for ensuring efficient and effective operations in various sectors, including industrial, commercial, and even residential applications.

With a plethora of options available in the market, it can be challenging to determine which pump type best suits your specific needs.

Factors such as the viscosity of the oil, the temperature at which it will be transferred, and the required flow rate must all be carefully considered.

Additionally, understanding the different types of pumps for oil—such as centrifugal, positive displacement, and diaphragm pumps—can help narrow down your choice.

This guide aims to shed light on the critical factors you should consider when selecting pumps for oil to optimize performance and minimize costs, ensuring that you find the perfect match for your unique applications and operational challenges.

Understanding the Different Types of Oil Pumps Available in the Market

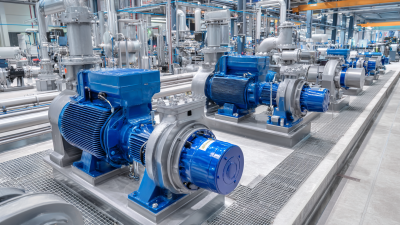

When selecting the right pump for oil applications, it's vital to understand the various types available in the market. Oil pumps can be categorized primarily into positive displacement pumps and centrifugal pumps. Positive displacement pumps are well-suited for viscous fluids, offering consistent flow regardless of pressure changes. They are ideal for transporting heavy oils and fluids with high viscosity. On the other hand, centrifugal pumps are commonly utilized for lower-viscosity oils and are great for high flow rates. They operate efficiently in applications where constant pressure is necessary.

Tips: When choosing an oil pump, consider the viscosity of the oil you'll be handling. This will significantly impact the pump's performance and efficiency. Additionally, think about the maximum flow rate required for your operations. It's also important to take into account the environment where the pump will be used—whether it’s indoors or outdoors, since this influences the pump's material and design.

Another crucial factor is the pump's compatibility with the specific type of oil being processed, as certain materials may react negatively with specific oil types, leading to degradation over time. Prioritize pumps that offer durability and resistance to wear for long-lasting performance. Therefore, understanding these types and their features ensures that you make an informed decision tailored to your operational needs.

Evaluating the Viscosity and Temperature Requirements for Oil Pump Selection

When selecting pumps for oil transfer, understanding the viscosity of the oil is crucial. The viscosity, a measure of a fluid's resistance to flow, significantly influences the type and design of pump that will perform effectively. For example, oils with a viscosity of 100 cP or less may suit centrifugal pumps, while those beyond 1,000 cP typically necessitate positive displacement pumps. According to the Hydraulic Institute, oil viscosity can vary widely depending on temperature and composition, making it essential to refer to specific data for each oil type you handle.

Temperature is another critical factor influencing pump performance. The viscosity of oils generally decreases as temperature increases, which can lead to significant changes in flow characteristics. For instance, at typical operational temperatures around 40°C, the viscosity of certain lubricating oils can drop by as much as 30%, leading to potential inadequacies in pump selection if not accounted for. The American Petroleum Institute notes that when handling heated oils, it’s vital to ensure that the selected pump can withstand both the operational and ambient temperatures to avoid failures or inefficiencies. Properly evaluating these parameters will lead to enhanced performance and longevity of the pumping system.

Assessing the Operational Environment and Its Impact on Pump Performance

When selecting pumps for oil, it’s essential to assess the operational environment, as it significantly influences pump performance. Factors such as temperature, pressure, and the presence of abrasive materials play a crucial role in determining the type of pump necessary for effective operation. For instance, high-temperature environments may require pumps constructed from specialized materials to prevent degradation, while systems that handle corrosive substances necessitate components that can withstand such conditions without compromising safety or efficiency.

Moreover, the layout of the installation site impacts the pump's operation and maintenance access. In cramped spaces, compact pump designs may be necessary, while large-scale operations might benefit from more robust models that can handle significant flow rates and pressures. Additionally, environmental considerations, such as the potential for spills or leaks in sensitive areas, must be factored in, influencing the choice of sealing mechanisms and containment systems. Adapting to these operational realities ensures optimal pump performance and longevity, aligning with the specific needs of oil management tasks.

Determining the Right Pump Capacity and Flow Rate for Your Application

When selecting the right pump for oil applications, it's vital to focus on capacity and flow rate based on your specific needs. Understanding the nature of the fluid being pumped, its viscosity, and temperature can help in determining the optimal pump. Oil can vary greatly in its characteristics, and a thorough assessment of these variables is essential for efficient operation.

When considering capacity, evaluate the total volume of oil you need to handle within a given timeframe. This will help you select a pump with a suitable flow rate, which is crucial for maintaining system efficiency. For applications requiring precise flow control, look for pumps that offer variable speed options.

**Tips:**

1. Always consult with manufacturers to match pump specifications with the oil type and application requirements.

2. Pay attention to the pump's efficiency ratings to minimize operational costs over time.

3. Think about maintenance requirements; choose a pump design that allows for easy access to components for routine checks and repairs.

With the global pump market projected to grow steadily, investing in the right technology is more important than ever. Ensuring that the chosen pump meets your flow rate needs will not only enhance performance but also contribute to long-term reliability and cost-effectiveness.

Choosing the Right Pumps for Oil Based on Your Specific Needs

Maintenance Considerations for Long-Term Operation of Oil Pumps

When selecting oil pumps, maintenance considerations play a crucial role in ensuring long-term operational efficiency and reliability. Regular inspection and servicing are vital to detect potential issues before they escalate. This includes checking for wear and tear on seals, couplings, and other moving parts. Keeping a maintenance log can help in tracking the performance patterns and understanding the pump’s health over time.

Proper lubrication and fluid management are essential for maintaining oil pumps, as they help in reducing friction and heat generation. It’s important to follow the manufacturer’s guidelines regarding the type of lubricants used and the frequency of oil changes. Additionally, ensuring that filters are replaced at recommended intervals can significantly enhance pump longevity. By prioritizing these maintenance practices, operators can minimize downtime, extend the life of the pump, and optimize its efficiency in handling oil-based fluids.

How to Choose the Right Pumps for Oil Based on Your Specific Needs - Maintenance Considerations for Long-Term Operation of Oil Pumps

| Pump Type | Max Flow Rate (GPM) | Operating Pressure (PSI) | Maintenance Frequency (Months) | Common Applications |

|---|---|---|---|---|

| Centrifugal Pump | 50 | 100 | 6 | Crude Oil Transfer |

| Positive Displacement Pump | 30 | 150 | 12 | Viscous Oil Handling |

| Submersible Pump | 40 | 80 | 9 | Well Oil Extraction |

| Diaphragm Pump | 20 | 90 | 4 | Chemical Injection |

| Gear Pump | 25 | 120 | 8 | Lubrication Systems |