Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

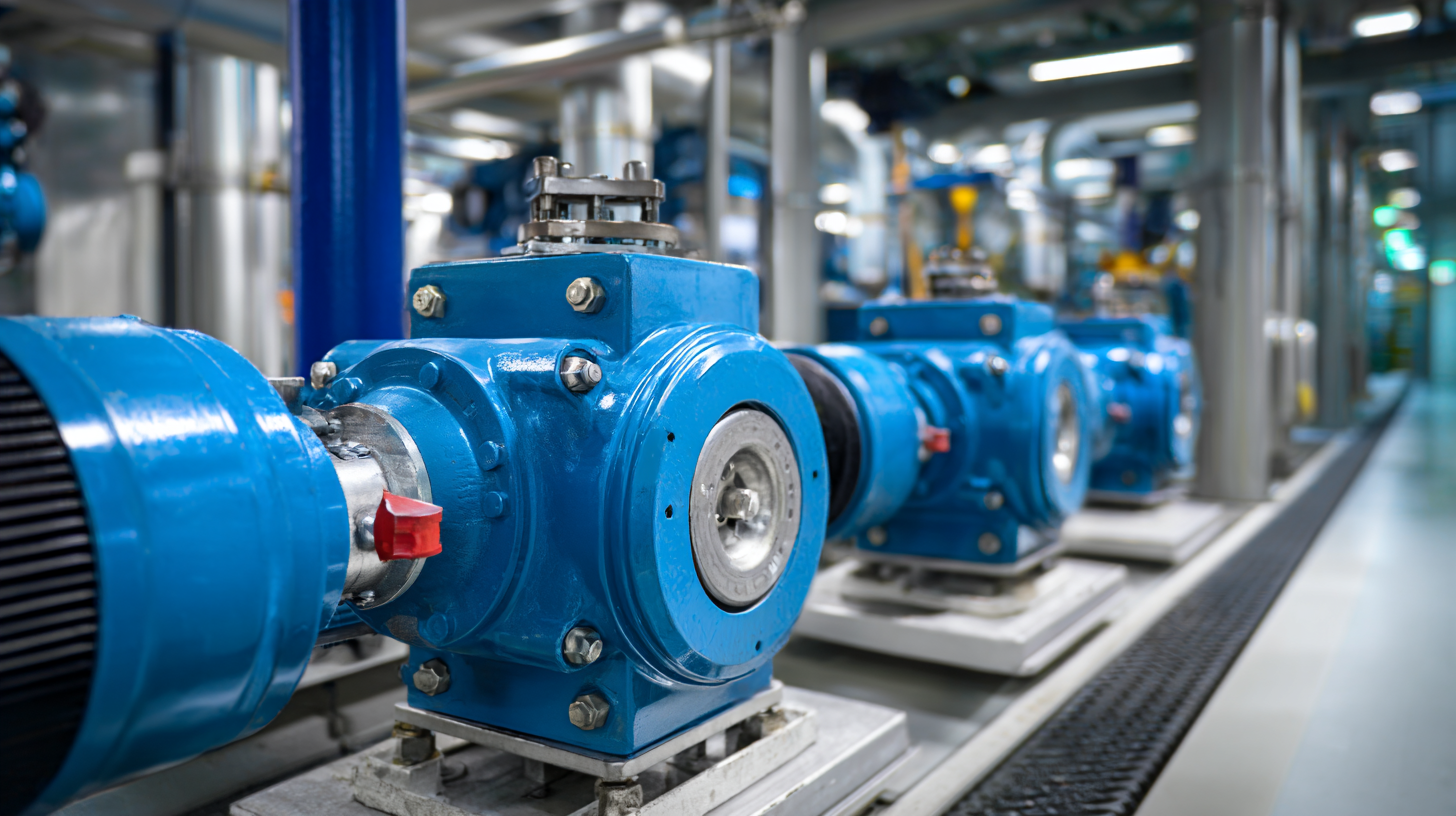

Cavity pumps, widely recognized for their efficiency and reliability in various industrial applications, have garnered significant attention in recent years. According to a report by the Global Market Insights, the global cavity pump market is projected to exceed $4 billion by 2026, driven by increasing demand across sectors such as chemical processing, water treatment, and mining. These pumps are distinguished by their unique design, which allows for smooth handling of viscous fluids and a range of solid materials, setting them apart from traditional pumping solutions. As industries seek improved operational efficiency and reduced downtime, cavity pumps are emerging as a favorable choice for many operators.

This comprehensive guide aims to explore the myriad benefits of cavity pumps, providing insights into their functionality, applications, and the competitive edge they offer in enhancing industrial processes.

Understanding Cavity Pumps: Key Features and Advantages

Cavity pumps, also known as progressive cavity pumps, are increasingly favored in various industrial applications due to their unique design and reliability. One of the key features of cavity pumps is their ability to handle a wide range of viscosities, making them suitable for transferring everything from thin liquids to thick sludges. According to a report from the Global Market Insights, the global cavity pump market is projected to grow at a CAGR of over 5% from 2020 to 2026, reflecting their rising significance in industries such as oil and gas, wastewater treatment, and food processing.

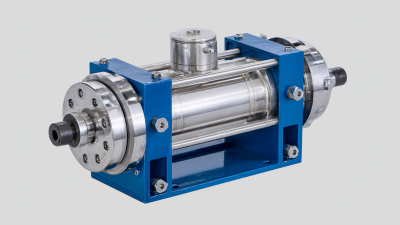

In addition to their versatility, cavity pumps are designed to provide a consistent flow rate regardless of the pressure variations they encounter. This characteristic is crucial for applications where precise dosing or transfer is required. Furthermore, the design minimizes turbulence, which prevents degradation of sensitive materials. Industry data suggests that cavity pumps can improve operational efficiency by up to 30%, which translates into significant cost savings for manufacturers.

**Tips:** When selecting a cavity pump, consider the specific viscosity and flow requirements of your application. Regular maintenance is essential to ensure optimal performance; schedule routine inspections to prevent downtime. Additionally, investing in high-quality materials can extend the lifespan of the pump, further enhancing cost-effectiveness.

Benefits of Cavity Pumps in Industrial Applications

How Cavity Pumps Enhance Efficiency in Various Industries

Cavity pumps have emerged as vital components in various industrial applications, primarily due to their ability to enhance efficiency. These positive displacement pumps are designed to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials. Their unique design, which employs a rotating cavity to move fluids, minimizes turbulence and optimizes flow rate, making them indispensable in industries such as oil and gas, food processing, and pharmaceuticals. By providing consistent flow and reducing the risk of fluid shear, cavity pumps contribute significantly to process reliability and product quality.

**Tips for Maximizing Efficiency with Cavity Pumps:**

1. Regular Maintenance: Ensure that pump components, such as seals and rotors, are regularly inspected and maintained to avoid downtime and maintain optimal performance.

2. Selecting the Right Pump: Match the cavity pump specifications to your fluid characteristics to maximize efficiency and ensure longevity.

3. Monitor Operating Conditions: Keep an eye on pressure and temperature to adjust operational parameters, ensuring the pump operates within its optimal range.

By leveraging the advantages of cavity pumps, industries can not only boost their efficiency but also improve operational sustainability, ultimately leading to reduced costs and better resource management.

Applications of Cavity Pumps in Chemical Processing and Manufacturing

Cavity pumps are becoming increasingly vital in the realm of

chemical processing and manufacturing due to their

unique capabilities in handling various materials. These pumps excel in transporting highly viscous fluids,

slurries, and shear-sensitive products, making them ideal for industries such as pharmaceuticals,

food and beverage, and petrochemicals. Their design enables efficient and gentle

pumping, which is essential when dealing with sensitive compounds that require minimal agitation during transfer.

Cavity pumps are becoming increasingly vital in the realm of

chemical processing and manufacturing due to their

unique capabilities in handling various materials. These pumps excel in transporting highly viscous fluids,

slurries, and shear-sensitive products, making them ideal for industries such as pharmaceuticals,

food and beverage, and petrochemicals. Their design enables efficient and gentle

pumping, which is essential when dealing with sensitive compounds that require minimal agitation during transfer.

In addition to their ability to handle complex materials, cavity pumps also offer enhanced operational efficiency and reliability. They can maintain a steady flow rate under varying pressure conditions, which is critical in chemical applications where precise measurement is necessary. Furthermore, their capacity for self-priming and dry-running without damage reduces downtime and maintenance costs, offering manufacturers greater operational flexibility. The versatility and robustness of cavity pumps make them an indispensable tool in improving productivity and ensuring consistent quality in chemical manufacturing processes.

Maintenance Best Practices for Ensuring Longevity of Cavity Pumps

Maintenance plays a crucial role in extending the lifespan and efficiency of cavity pumps in industrial applications. Regular monitoring and adherence to manufacturer-recommended servicing schedules can prevent premature wear and unexpected failures. One effective practice is to keep the pump components clean and free from debris, which can cause blockages and hinder performance. Additionally, ensuring that seals and bearings are adequately lubricated minimizes friction and reduces the likelihood of equipment failure.

Another critical aspect of maintenance is the regular inspection of the pump system for any signs of wear or damage. This can include checking for leaks, abnormal vibrations, and temperature fluctuations that may indicate underlying issues. Implementing a routine maintenance checklist can aid in identifying these potential problems early on. Furthermore, training operators and maintenance personnel on the specific requirements and configurations of cavity pumps ensures that any adjustments or repairs are performed correctly, enhancing overall reliability and operational performance.

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide - Maintenance Best Practices for Ensuring Longevity of Cavity Pumps

| Dimension | Description | Benefits | Maintenance Tips |

|---|---|---|---|

| Efficiency | Cavity pumps are designed for high efficiency in transferring viscous fluids. | Reduced energy consumption and operational costs. | Regularly check for wear and maintain optimal fluid temperature. |

| Versatility | Can handle a wide range of fluids, including those containing solids. | Applicable in various industries such as food processing, pharmaceuticals, and wastewater. | Inspect pumps regularly for blockages or contamination. |

| Durability | Constructed for long-lasting performance even in harsh environments. | Lower replacement costs and decreased downtime. | Follow manufacturer guidelines for lubrication and part replacements. |

| Maintenance | Requires routine maintenance checks to ensure optimal function. | Extended lifespan of the pump enhances overall system reliability. | Schedule periodic maintenance and keep detailed service records. |

| Safety | Designed with safety features to prevent leaks and spills. | Minimizes risk of accidents and environmental hazards. | Regularly inspect safety features and emergency shutdown systems. |

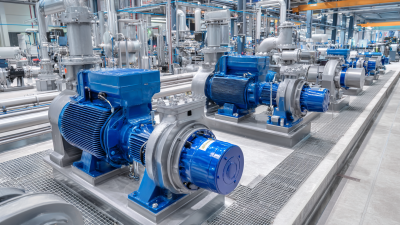

Comparing Cavity Pumps with Other Types of Pumps for Industrial Use

Cavity pumps have emerged as a vital component in various industrial applications, particularly when compared to traditional pumping solutions like electric submersible pumps (ESP) and sucker rod pumps (SRP). The global market for artificial lift systems indicates a projected growth with a compound annual growth rate (CAGR) of 5.8%, underscoring the significance of innovative pump technologies. Progressive cavity pumps, categorized under these artificial lift systems, are noted for their ability to handle viscous fluids and high solids content, making them indispensable in sectors such as oil and gas, water treatment, and food processing.

In contrast to other types of pumps, cavity pumps offer unique advantages, including the capability for continuous and consistent flow rates. This is particularly beneficial in applications requiring precise dosing and transfer of materials. According to recent market reports, the industrial pump market is set to expand from $70.45 billion in 2024 to $105.15 billion by 2032, driven in part by the increasing adoption of positive displacement pumps like cavity pumps, which provide efficiency in energy consumption and reduced operational costs. This trend emphasizes the importance of selecting the appropriate pump type for specific industrial needs to maximize performance and operational reliability.

Related Posts

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

How to Choose the Right Type of Industrial Pump for Your Application

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair