10 Best Screw Pumps for Efficient Fluids Management in 2026?

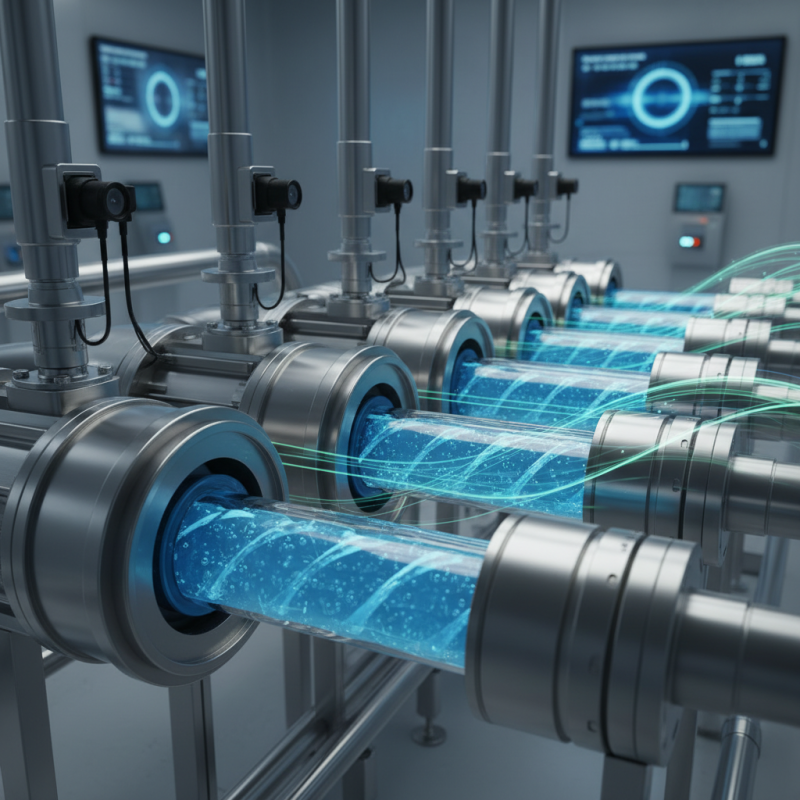

In the evolving landscape of fluid management, screw pumps play a crucial role. As industry expert Dr. Emily Johnson notes, "Screw pumps efficiently handle diverse fluids." This statement captures the essence of their functionality. By utilizing a unique mechanism, these pumps deliver consistent flow rates with minimal pulsation, making them ideal for various applications.

The demand for screw pumps is rising. Industries like chemical processing and food production benefit greatly from their reliability. These pumps can handle thick and viscous materials, which other pumps struggle with. Yet, not all screw pumps are created equal. Some lack durability and efficiency, leading to frequent maintenance issues.

As we look toward 2026, it’s necessary to evaluate the top screw pumps available. Innovations are continually shaping this sector, but challenges remain. Users often overlook essential features. In the quest for reliability, a deeper understanding is needed to select the right pump for the job. This guide will explore the ten best screw pumps to enhance fluid management in the coming years.

10 Key Factors Driving the Evolution of Screw Pumps in 2026

The evolution of screw pumps in 2026 is driven by several key factors. One major aspect is the push for energy efficiency. Industries rely on pumps to manage fluids sustainably. As energy prices rise, companies seek better performance and lower operating costs. New designs focus on minimizing energy loss during operation. This is a crucial aspect for sectors like oil and gas, where every unit counts.

Another important factor is the incorporation of smart technology. Smart sensors and IoT connectivity allow for real-time monitoring. This enables operators to adjust performance dynamically. Predictive maintenance reduces downtime significantly. Connectivity brings improved data flow and insights, enhancing decision-making. However, many companies face challenges in integrating these technologies. Not all workers are trained in new systems, causing a learning curve.

Environmental concerns also play a role. Manufacturers are under pressure to reduce waste and minimize emissions. Improved materials and processes are needed to create eco-friendly pumps. Yet, some companies struggle with this transition. Balancing cost and sustainability is not straightforward. Addressing these challenges will shape the future of screw pumps fundamentally.

Comparative Analysis: Leading Screw Pump Brands and Their Market Shares

As industries evolve, the demand for efficient fluid management grows. The screw pump market has seen significant advancements. Various brands now offer innovative solutions that cater to diverse operational needs. Understanding their market shares is crucial for making informed decisions.

In 2026, several brands will dominate the screw pump arena. Each brand exhibits unique features, which contribute to their popularity. Some emphasize energy efficiency, while others focus on durability and versatility. However, the competition is fierce. Many brands struggle to maintain consistent performance across different applications. This inconsistency raises questions about long-term viability.

The analysis also reveals that some brands are gaining market shares rapidly. Others are facing stagnation. This disparity often stems from product innovation and customer feedback. For instance, brands that adapt quickly to market changes tend to thrive. However, companies that resist change may find themselves losing relevance. The landscape is shifting, making adaptability essential for success.

Technological Innovations Enhancing Screw Pump Efficiency and Performance

Screw pumps are evolving rapidly. In 2026, innovative designs and materials promise to boost efficiency. These pumps enhance fluid management in various industries, from oil to food processing. The latest models feature advanced screw profiles that reduce energy loss significantly. This new geometry offers smoother fluid flow and decreased wear.

Moreover, integration of IoT technology allows real-time monitoring. Operators receive alerts for potential failures before they occur. This proactive approach minimizes downtime. However, the reliance on technology raises concerns. What happens if the system fails? Human oversight remains crucial to avoid over-reliance on digital solutions.

Recent developments in materials also play a vital role. New composites resist corrosion and wear, extending pump life. Yet, transitioning to these materials can be costly for some operators. Balancing efficiency and budget constraints is essential. As the landscape of screw pumps shifts, these innovations reflect a blend of progress and caution. The road ahead is promising but requires careful navigation.

Applications of Screw Pumps Across Various Industries and Their Benefits

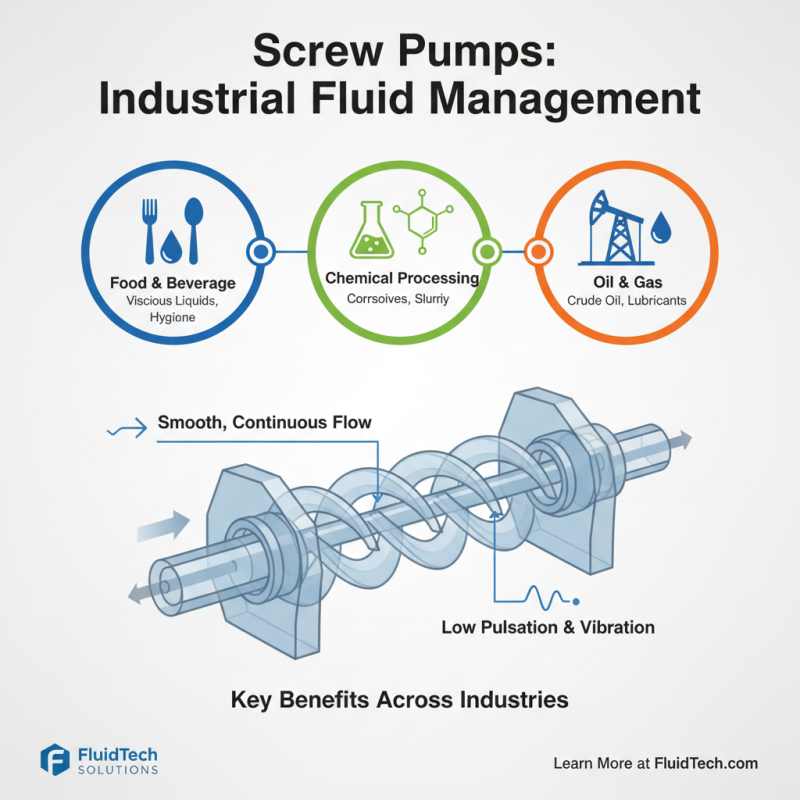

Screw pumps are vital for managing fluids across various industries. They excel in the food, chemical, and oil sectors. These pumps handle viscous fluids efficiently. Their design allows for smooth and continuous flow. This functionality minimizes pulsation and vibration during operation.

In the food industry, screw pumps transport pastes and slurries. They maintain product integrity without damaging sensitive components. In chemical processing, these pumps manage corrosive materials effectively. Their robust construction ensures safety and reliability. Many facilities also value their low maintenance needs.

However, some challenges exist. Proper selection is crucial to avoid inefficiencies. Operators must understand fluid characteristics for optimal performance. Sometimes, pump wear can lead to unexpected downtime. Regular monitoring is needed to address wear issues promptly. Despite their advantages, the learning curve for new users can be steep.

Future Trends in Screw Pump Design for Improved Fluid Management Systems

The future of screw pump design is promising. As industries prioritize efficient fluid management, innovative technologies are driving change. According to recent reports, the global screw pump market is expected to grow significantly, with a compound annual growth rate (CAGR) of around 5% by 2026. This growth is fueled by advancements in materials and engineering techniques.

One emerging trend is the push for more energy-efficient designs. Many manufacturers are focusing on reducing energy consumption while maintaining high performance. This shift can cut operational costs significantly, especially for industries that rely heavily on fluid transport. Moreover, integrating smart technology into screw pumps can provide real-time monitoring capabilities. This allows for better maintenance and reduced downtime, addressing some of the industry's recurring challenges.

However, challenges remain. Designing pumps that can handle diverse fluid properties effectively is complex. Not all innovations may translate into real-world efficiency improvements. Some designs may appear optimal on paper but fail under actual conditions. Industry experts emphasize the need for rigorous testing and validation processes. Feedback loops from end-users are crucial for refining these systems further. Emphasizing collaboration between engineers and operators is essential for achieving optimal outcomes.

Related Posts

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Understanding the Benefits of Screw Pumps in Modern Industrial Applications

-

High Pressure Screw Pump Tips for Optimal Performance and Maintenance

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Top Twin Screw Pump Manufacturers You Should Know About in 2023