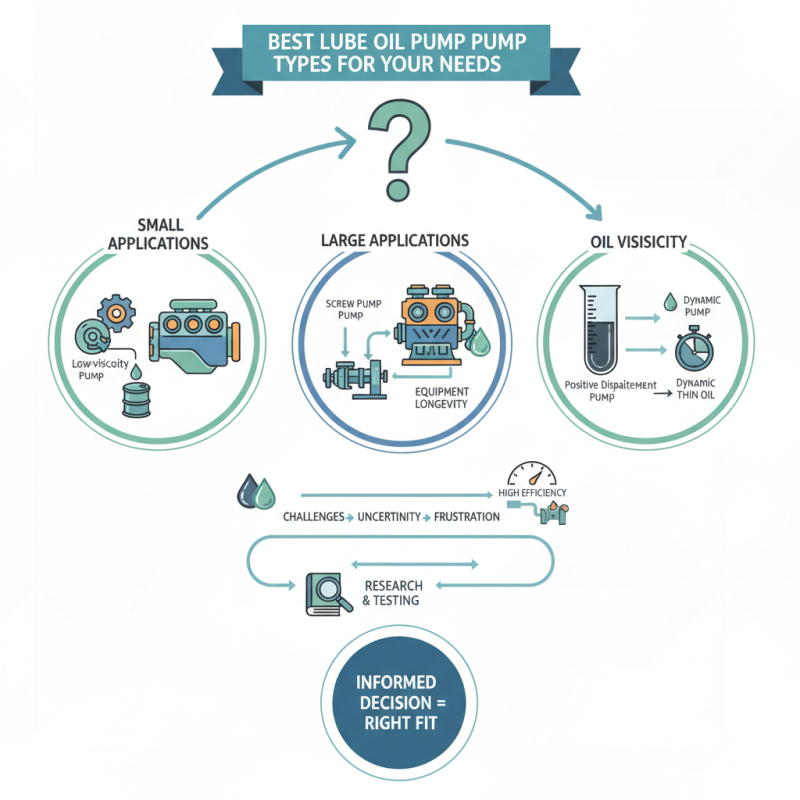

Best Lube Oil Pump Types for Your Needs?

Choosing the right lube oil pump can be challenging. There are many types available, each with unique features. Understanding your needs is crucial for making the right choice.

Lube oil pumps vary widely in design and function. Some are ideal for smaller applications, while others suit larger engines. The right pump ensures efficiency and longevity of equipment. It's vital to assess the viscosity of oil you plan to use. Not all pumps handle all types of lubricant equally well.

You may encounter unexpected challenges with some lube oil pump models. Not every option will fit your specific requirements. This uncertainty can lead to potential frustrations. Research and testing different pumps can uncover valuable insights. By learning more, you can make an informed decision that truly fits your needs.

Overview of Lubrication Systems and Their Importance

Lubrication systems play a crucial role in many mechanical operations. They reduce friction between moving parts, preventing wear and tear. This increases the lifespan of machinery. Proper lubrication ensures smooth operation and higher efficiency. Without it, machines can overheat and fail.

Choosing the right lube oil pump is essential for effective lubrication. Different machines have unique requirements. Some may need high-pressure systems, while others might require lower flow rates. It’s important to understand your equipment’s needs. Incorrect oil viscosity can lead to problems. Sometimes, a simple change can make a significant difference.

Regular maintenance of lubrication systems is often overlooked. Neglect can result in a harsh operating environment. Monitoring oil levels and checking for contamination should be routine. If lubrication fails, the consequences can be severe. Rethink your lubrication strategy to avoid potential pitfalls. Balancing performance and reliability is key in any industrial setting.

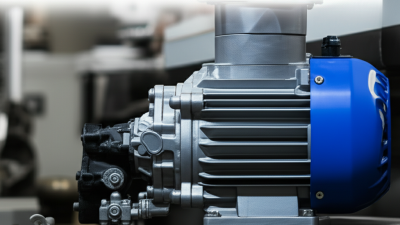

Different Types of Lube Oil Pumps and Their Functions

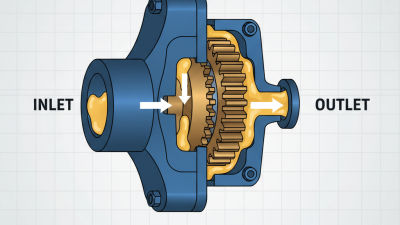

When selecting a lube oil pump, understanding the different types is crucial for meeting your specific needs. Common types include gear pumps, diaphragm pumps, and screw pumps.

Gear pumps are widely used in industrial applications due to their efficiency and reliability. They can handle high viscosity oils and maintain consistent flow rates. According to industry reports, gear pumps account for nearly 45% of the market due to their simplicity and robust performance.

Diaphragm pumps offer versatile solutions for low-viscosity fluids. They are ideal for applications where fluid contamination is a concern. Their ability to create a vacuum during operation minimizes the risk of leaks and spills. This makes them a popular choice in many chemical processing industries. Data shows that diaphragm pumps are gaining traction, representing about 30% of the lube oil pump market.

Tip: When choosing a pump, consider the viscosity of your lubricant. It's essential to match the pump type with your application for optimal results.

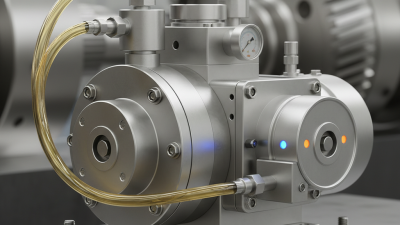

Screw pumps are known for their ability to handle various fluids, including those with particulates. They are robust and often used in heavy-duty applications. However, they can be more expensive and may require more maintenance. It's important to weigh the costs against the benefits they provide.

Tip: Regular maintenance is vital for all pump types. It can prevent unexpected breakdowns and extend their life. Don't overlook this essential practice.

Factors to Consider When Choosing a Lube Oil Pump

When choosing a lube oil pump, several factors come into play. Consider the application where the pump will be used. Different machines require different types of pumps. For instance, heavy machinery may need robust pumps built to handle high viscosity oils.

The flow rate is another crucial factor. Determine the required flow rate for your application. Too low a rate may lead to insufficient lubrication, while too high can result in wastage. Also, consider the pump's efficiency. Look for a model that minimizes energy consumption where possible.

Tips: Always check compatibility with your oil type. Some pumps work better with certain oils. Pay attention to maintenance needs. High-maintenance pumps may lead to higher running costs in the long run. Reflect on the long-term implications of your choice. A less efficient pump may save you money upfront but cost more in upkeep.

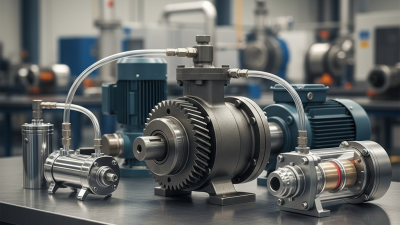

Comparative Analysis of Common Lube Oil Pump Types

When it comes to lube oil pumps, several types stand out, each with its unique features. Gear pumps are popular due to their simplicity and reliability. They effectively move oil through tight spaces. However, they can have issues if there's contamination. Diaphragm pumps offer safe fluid handling. They minimize leaks and are versatile for different fluids. Yet, they can be prone to wear over time, requiring careful monitoring.

Centrifugal pumps are another common choice. They work well in larger systems and can handle high flow rates. Their efficiency is often commendable, but they may struggle with varying oil viscosities. Some users report inconsistent performance under certain conditions. Moreover, screw pumps provide excellent precision and are suitable for thick oils. They deliver smooth flow, but maintenance can be challenging.

Understanding these differences is vital for making the right choice. Each type has strengths and weaknesses. Assess your specific needs before deciding. The wrong pump can lead to operational failures or inefficiencies.

Best Lube Oil Pump Types for Your Needs

This chart compares different types of lube oil pumps based on their flow rate and efficiency. The data provides insights into which pump type might best suit your needs depending on performance criteria.

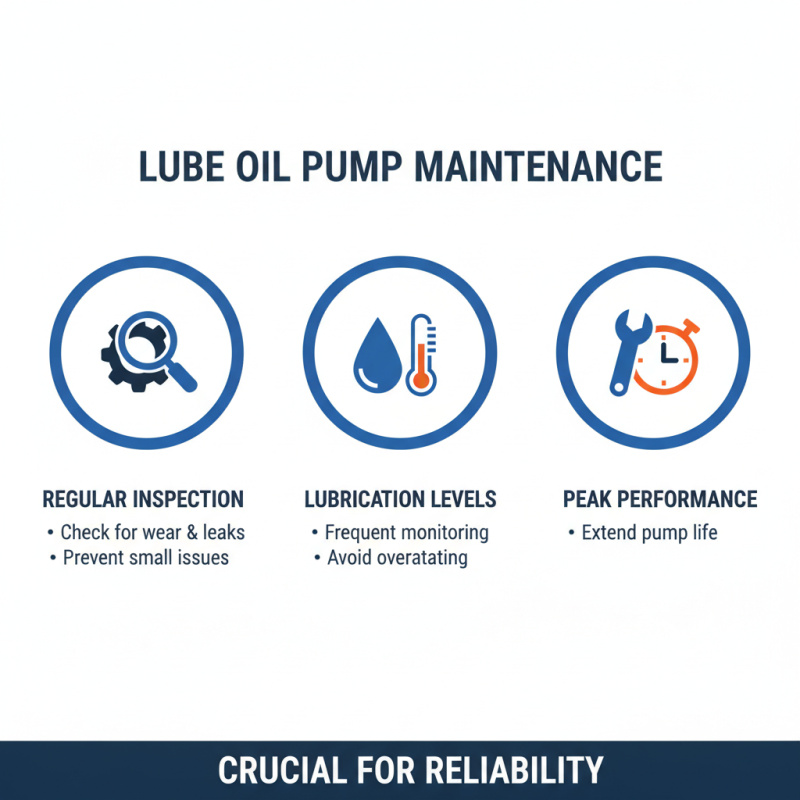

Maintenance Tips for Maximizing Lube Oil Pump Performance

Regular maintenance is crucial for ensuring the peak performance of lube oil pumps. Start by inspecting the pump regularly. Look for any signs of wear or leaks. A small leak can quickly worsen, leading to more significant issues. Check the lubrication levels frequently. If levels drop, the pump can overheat. This may cause it to fail prematurely.

Cleaning is another key aspect of maintenance. Dirt and debris can clog filters and impact performance. Make a routine of replacing the filters regularly. It's a simple task but highly effective. Sometimes, ignoring these tasks can lead to larger problems down the road.

Additionally, monitor the oil condition. If it turns dark or develops a strange odor, it may need changing. Proper oil selection also plays a role. Using the right type can enhance pump longevity. Remember, every pump has its quirks. Understanding these can help you avoid mistakes in the long run.

Related Posts

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

Top Lube Pump Types for Efficient Fluid Transfer Solutions?

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

2026 Best Oil Lubrication Pump for Enhanced Machinery Performance?