Understanding the Benefits of Screw Pumps in Modern Industrial Applications

In the realm of modern industrial applications, screw pumps have emerged as a vital component, revolutionizing the way fluids are transported and managed. Understanding the benefits of screw pumps not only enhances operational efficiency but also significantly reduces maintenance costs and downtime in various sectors, from oil and gas to food processing.

The unique design of screw pumps allows for gentle fluid handling and the ability to convey highly viscous materials, making them an excellent choice for a wide range of applications. Furthermore, their continuous flow characteristics ensure a steady supply, minimizing pulsation and pressure surges that are often problematic in other pumping systems.

This article delves into the myriad advantages of screw pumps, providing insights into their functionality, applications, and the reasons they are becoming increasingly favored in today’s industrial landscape. By exploring the diverse benefits these pumps offer, industries can better equip themselves to meet the challenges of modern fluid management.

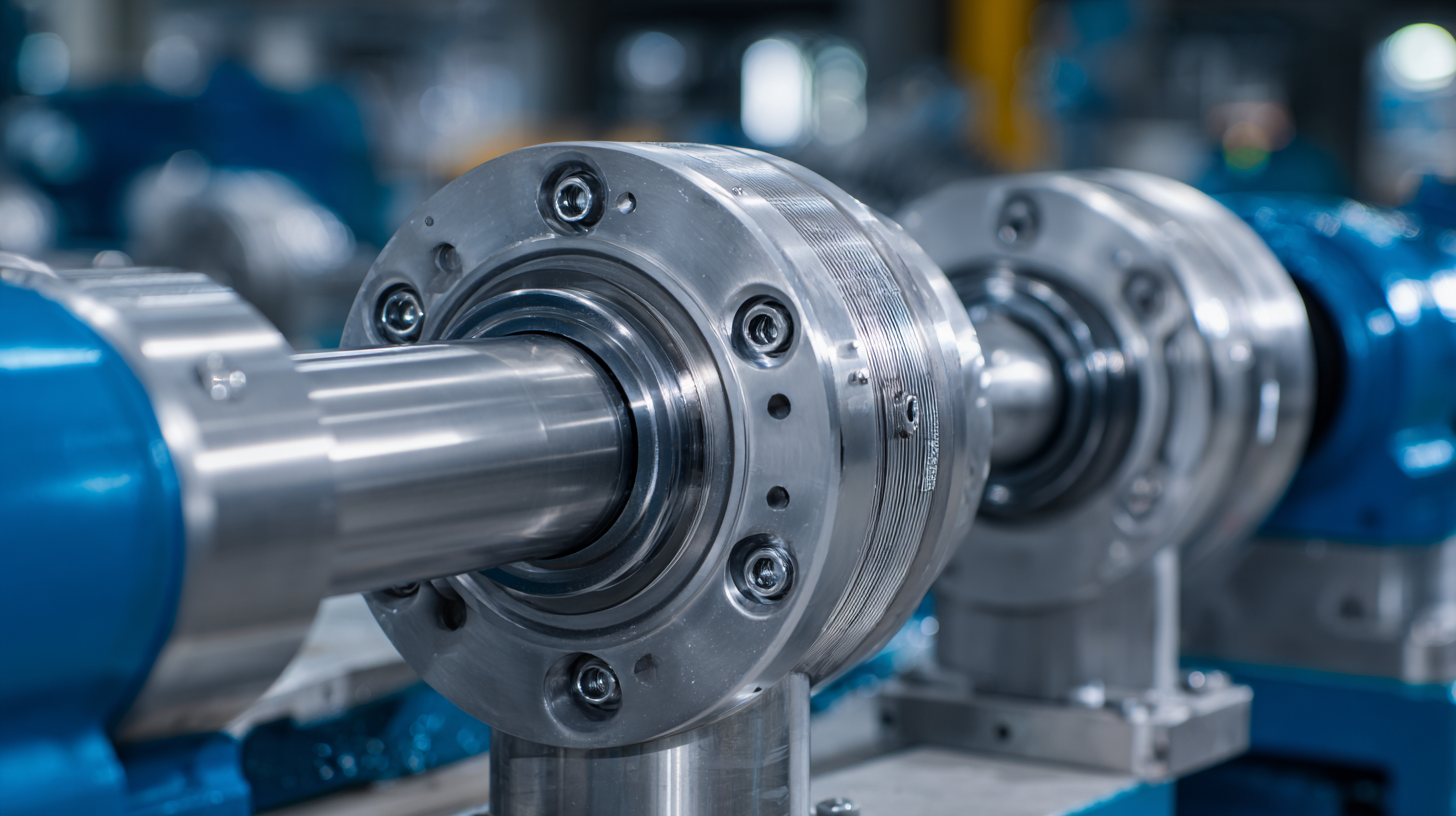

How Screw Pumps Operate: A Comprehensive Guide to Their Mechanism

Screw pumps are essential components in modern industrial applications, renowned for their efficiency and reliability in transferring fluids. These pumps operate on a simple yet effective mechanism involving two or more helical screws that rotate within a chamber. As the screws turn, they create a continuous flow of fluid by pushing it along the screw's axis, minimizing pulsation and allowing for a smooth, steady discharge. According to a report by the Hydraulic Institute, screw pumps can achieve efficiency levels exceeding 90%, making them suitable for handling viscous fluids that traditional centrifugal pumps struggle with.

The versatility of screw pumps is illustrated by their capacity to manage a wide range of fluid properties, including viscosity and temperature. The American Society of Mechanical Engineers (ASME) highlights that screw pumps can successfully handle fluids with viscosities up to 500,000 cP, which is critical in industries such as oil and gas, wastewater treatment, and food processing. Furthermore, their ability to operate with low shear makes them ideal for transporting shear-sensitive materials, ensuring product quality is maintained throughout the pumping process. This unique mechanism combines with a robust design, providing longevity and reducing maintenance costs, enhancing their appeal in various industrial settings.

Key Advantages of Using Screw Pumps in Industrial Applications

Screw pumps have gained significant traction in modern industrial applications due to their distinctive advantages that enhance efficiency and performance. One of the key benefits is their ability to handle a wide range of viscosities, making them ideal for industries dealing with heavy fluids such as oils and slurries. According to a recent report by the International Journal of Fluid Mechanics, screw pumps can efficiently manage fluids with viscosities exceeding 1,000 cP, outperforming traditional pumps that struggle with such densities. This versatility enables industries like chemical processing and food production to maintain smooth operations without frequent equipment failures.

Another advantage of screw pumps is their low pulsation output, which contributes to improved flow stability. This characteristic is crucial in processes where consistent flow rates are essential, such as in pharmaceutical manufacturing. A report by the American Society of Mechanical Engineers noted that screw pumps deliver a steady flow with less than 5% pulsation, compared to centrifugal pumps, which can exhibit fluctuating outputs. This stability not only enhances product quality but also reduces wear and tear on machinery, leading to lower maintenance costs and extended operational lifespans. As industries continue to prioritize efficiency and sustainability, the screw pump’s reliability and performance position it as a favorable choice across various sectors.

Understanding the Benefits of Screw Pumps in Modern Industrial Applications

| Advantage | Description | Typical Applications | Efficiency |

|---|---|---|---|

| High Viscosity Handling | Exceptional capability to pump fluids with high viscosity without degradation. | Oil & Gas, Food Processing | 80-90% |

| Durability | Designed to withstand tough operating conditions, leading to longer service life. | Mining, Wastewater Treatment | 85-95% |

| Continuous Flow | Provides a steady and consistent flow rate, reducing pulsation. | Chemical Processing, HVAC Systems | 90-95% |

| Self-Priming | Eliminates the need for an external priming system, reducing setup time. | Agriculture, Petrochemical | 82-88% |

| Versatility | Effective for a wide range of fluids, including corrosive and abrasive materials. | Pharmaceuticals, Cosmetics | 86-92% |

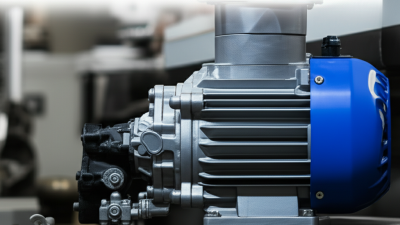

Choosing the Right Screw Pump for Your Specific Needs

When choosing the right screw pump for your specific needs, it's important to consider several key factors. First and foremost, you should evaluate the type of fluid being handled. For instance, twin screw pumps are highly regarded in industries like oil, gas, and chemicals due to their exceptional ability to manage viscous materials efficiently. Understanding the characteristics of the fluid, including its viscosity, temperature, and whether it contains solids, will guide you towards the most suitable design and configuration.

Another critical factor is the intended application and required flow rates. Different industries may demand varied performance specifications; thus, it’s essential to consult manufacturers about their pump offerings. Features such as pressure ratings, materials of construction, and energy efficiency should align with operational needs and regulatory standards. Additionally, regular maintenance needs and the potential for scalability in production should be considered to ensure longevity and cost-effectiveness in your investment. Properly assessing these elements will help in selecting a screw pump that meets both current demands and future growth expectations.

Understanding the Benefits of Screw Pumps in Modern Industrial Applications

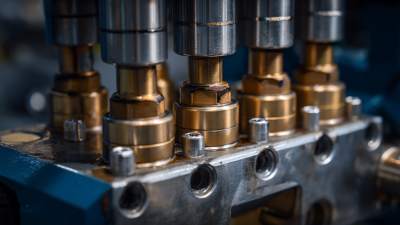

Maintenance Tips for Maximizing Screw Pump Efficiency and Longevity

Screw pumps have gained prominence in various industrial applications due to their ability to handle high viscosity fluids and operate under demanding conditions. To maximize the efficiency and longevity of these pumps, proper maintenance is essential. According to the Hydraulic Institute, periodic maintenance can improve pump reliability by up to 60%, leading to reduced downtime and lower operational costs.

One vital tip for maintaining screw pumps is to regularly check for wear and tear on the screws and housing. Implementing a routine inspection schedule, ideally every 200 to 500 hours of operation, can help identify issues before they escalate. Additionally, ensuring that the pump is always operated within its specified parameters, such as pressure and temperature limits, will significantly enhance its lifespan. A study from the American Society of Mechanical Engineers highlights that over 80% of pump failures are linked to improper operational practices.

Another important aspect of maintenance involves lubrication. According to industry guidelines, using the correct lubricant reduces friction and helps prevent overheating. Regularly replacing the lubricant every 1,000 operational hours or as per the manufacturer’s recommendations can help maintain optimal performance. By adhering to these maintenance tips, operators can ensure their screw pumps operate efficiently and last longer, ultimately saving costs in the long run.

Common Industries Benefiting from Screw Pump Technology

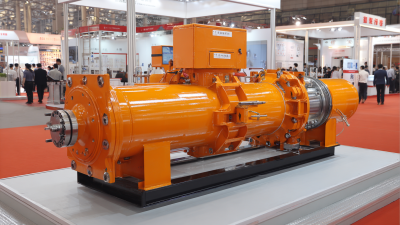

Screw pumps have emerged as pivotal tools across several modern industrial sectors, demonstrating their versatility in both traditional and contemporary applications. One of the most notable areas is the oil and gas industry, where these pumps are increasingly adopted for enhanced efficiency in crude oil transportation and processing. The ongoing shift towards multi screw pumps has revolutionized how this sector operates, boasting higher reliability and reducing operational costs.

Screw pumps have emerged as pivotal tools across several modern industrial sectors, demonstrating their versatility in both traditional and contemporary applications. One of the most notable areas is the oil and gas industry, where these pumps are increasingly adopted for enhanced efficiency in crude oil transportation and processing. The ongoing shift towards multi screw pumps has revolutionized how this sector operates, boasting higher reliability and reducing operational costs.

In addition to oil and gas, the power industry is witnessing innovative applications of screw pump technology. With a significant transition in fuel types for power generation, legacy power plants are incorporating these pumps to improve their overall performance and streamline operations. As these plants adapt, screw pumps offer solutions for handling various liquids efficiently, thus addressing the industry's evolving needs.

Tip: When selecting a screw pump for your application, consider the specific fluid properties and the operational environment to ensure optimal performance.

Another key industry benefiting from screw pump technology is the semiconductor sector. As this industry expands, the demand for reliable dry vacuum pumps is also on the rise. Utilizing screw pumps can help maintain the necessary precision and cleanliness required in semiconductor manufacturing processes, ensuring high product quality.

Tip: Regular maintenance and tailored pump configurations can significantly enhance the lifespan and efficiency of screw pumps in demanding applications.

Related Posts

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity