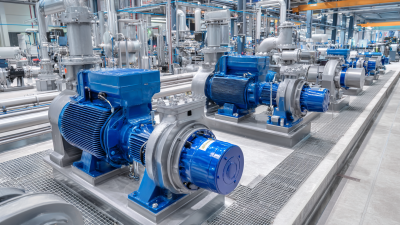

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

The utilization of high pressure positive displacement pumps in industrial applications has gained significant traction, driven by their efficiency and reliability in handling various fluids under demanding conditions. According to a recent report by MarketsandMarkets, the global positive displacement pump market is projected to reach $22.5 billion by 2026, with a notable shift towards high-pressure systems in sectors such as oil and gas, chemical processing, and water treatment. These pumps offer consistent flow rates regardless of pressure variations, making them ideal for processes that require precise fluid movement.

Additionally, their ability to manage thick and viscous materials enhances operational productivity while reducing downtime. As industries continue to innovate and seek cost-effective solutions, understanding the advantages and applications of high pressure positive displacement pumps becomes essential for optimizing processes and achieving long-term success.

Understanding High Pressure Positive Displacement Pumps and Their Mechanism

High pressure positive displacement pumps are essential tools in various industrial settings due to their unique operating mechanism. Unlike centrifugal pumps that rely on rotational kinetic energy, these pumps move fluids by trapping a fixed amount of liquid and forcing it through the discharge pipe. This mechanism allows for precise flow control and the handling of highly viscous fluids, making them ideal for applications such as chemical processing, oil & gas, and food production. According to a recent report by MarketsandMarkets, the global positive displacement pumps market is expected to reach $12.3 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 6.2%, indicating a growing reliance on these pumps for efficient fluid management.

Tips: When selecting a high pressure positive displacement pump, consider the fluid properties and required flow rates. Ensure compatibility with the materials being pumped to avoid corrosion or degradation. Proper maintenance is crucial; regular inspections can prevent costly downtime and extend the pump's lifespan.

Additionally, high pressure systems typically operate between 500 to 5000 psi, allowing for robust pressure applications. A benefit of this design is their ability to maintain consistent flow rates, even under varying pressure conditions. According to the Hydraulic Institute, these pumps can achieve efficiencies of up to 90%, proving essential for energy conservation in industrial processes.

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

This chart illustrates the various benefits of high pressure positive displacement pumps in industrial applications, rating each benefit on a scale from 1 to 10. The metrics evaluated include efficiency, durability, maintenance requirements, cost-effectiveness, and versatility, highlighting their significance in optimizing industrial processes.

Key Advantages of Using High Pressure Positive Displacement Pumps in Various Industries

High pressure positive displacement pumps offer numerous advantages that make them invaluable across various industrial applications. One of the key benefits is their ability to deliver a consistent and precise flow rate, regardless of changes in pressure. This feature is particularly advantageous in industries such as chemical processing and pharmaceuticals, where maintaining strict control over fluid transfer is essential for product quality and safety.

Additionally, these pumps can efficiently handle high-viscosity fluids and slurries, which are common in sectors such as oil and gas as well as mining. Their design allows for reliable operation under high-pressure conditions, ensuring efficient transport of challenging materials without compromising performance.

Furthermore, positive displacement pumps can also reduce energy consumption compared to other pumping technologies, leading to lower operational costs and a reduced environmental footprint for industrial plants. Overall, the unique capabilities of high pressure positive displacement pumps make them a preferred choice for many sectors seeking efficiency and reliability in their operations.

Comparative Analysis: High Pressure Positive Displacement Pumps vs. Centrifugal Pumps

High pressure positive displacement (HPPD) pumps and centrifugal pumps are two predominant technologies in the industrial landscape, each suited for specific applications. HPPD pumps are efficient at moving viscous fluids and are often employed in industries such as oil and gas, pharmaceuticals, and food processing. According to a report by Market Research Future, the demand for HPPD pumps is projected to grow significantly, with a compound annual growth rate (CAGR) of around 6.5% from 2020 to 2026. This growth is driven by their capability to maintain a consistent flow rate under varying pressure conditions, which is crucial for processes requiring precise fluid dynamics.

In contrast, centrifugal pumps are widely used for lower viscosity liquids and are typically favored for their simple construction and ease of maintenance. However, they often struggle with high viscosity fluids, leading to inefficiencies. A comparative study by the Hydraulic Institute indicates that while centrifugal pumps can achieve higher flow rates, they experience a drop in performance as the viscosity of the fluid increases. This highlights a significant advantage of HPPD pumps, which can handle a wider range of fluid properties without sacrificing performance. Thus, the choice between these pump types ultimately depends on the specific application requirements and the characteristics of the fluids being handled.

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications - Comparative Analysis: High Pressure Positive Displacement Pumps vs. Centrifugal Pumps

| Parameter | High Pressure Positive Displacement Pumps | Centrifugal Pumps |

|---|---|---|

| Operating Pressure Range | Up to 1000 bar | Up to 40 bar |

| Flow Rate Range | 0.1 to 1000 L/min | 1 to 500 L/min |

| Efficiency | 70-90% | 50-75% |

| Viscosity Handling | Suitable for high-viscosity fluids | Limited to low-viscosity fluids |

| Maintenance Requirements | Moderate, but more complex | Lower, simpler design |

| Typical Applications | Petrochemical, Food Processing, Pharmaceuticals | Water Supply, Cooling Systems, HVAC |

Applications of High Pressure Positive Displacement Pumps in Chemical Processing and Water Treatment

High pressure positive displacement pumps are increasingly vital in various industrial applications, particularly in chemical processing and water treatment. These pumps excel at handling high-viscosity fluids and delivering precise flow rates, making them ideal for the intricate demands of the chemical industry. In processes like polymer production and the handling of corrosive materials, the reliability and efficiency of these pumps ensure consistent performance and minimize downtime, significantly impacting operational costs.

In the realm of water treatment, high pressure positive displacement pumps play a crucial role in processes such as desalination and wastewater management. Their ability to generate the high pressures required for effective filtration and reverse osmosis systems enhances water quality and availability. As industries focus on sustainability and efficient resource management, the need for robust water treatment solutions continues to grow.

The global dosage pump market, projected to expand from $6.35 billion in 2025 to $9.06 billion by 2032, reflects this increasing demand, with a compound annual growth rate of 5.21%. This growth underscores the essential role of high pressure positive displacement pumps in meeting the evolving needs of industrial applications.

Maintenance Best Practices for High Pressure Positive Displacement Pumps in Industrial Settings

Proper maintenance of high pressure positive displacement pumps is essential for ensuring their efficiency and longevity in industrial settings. Regular monitoring of key components, such as seals and valves, can prevent unexpected breakdowns. Operators should establish a routine inspection schedule, checking for wear and tear, leaks, and unusual noises. Implementing a system for tracking maintenance activities and identifying patterns in pump performance can also aid in early detection of potential issues.

Another best practice involves maintaining optimal fluid conditions. Ensuring that the pump operates within its specified temperature and viscosity ranges can significantly reduce strain on the system. Regularly flushing the pump and using the correct lubricants contributes to smoother operations and minimizes the risk of damage. Additionally, training personnel on the specific requirements and operational parameters of the pumps they work with enhances overall awareness, leading to proactive maintenance and reduced downtime.

Related Posts

-

How to Choose the Right Type of Industrial Pump for Your Application

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency