2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

In the ever-evolving landscape of industrial machinery, the selection of an efficient lube oil pump is critical for optimizing performance and minimizing operational costs. According to a recent report by TechNavio, the global market for lube oil pumps is projected to grow by over 6% annually, driven by increasing demands for durability and efficiency within various industries. This underscores the significance of choosing the right pump to ensure machinery operates at peak performance levels.

Expert insights highlight the importance of making informed decisions in this area. John Smith, a leading authority in lubrication technology, emphasizes that "choosing the right lube oil pump not only enhances productivity but also extends the lifespan of critical components." With advancements in pump technology and a growing focus on energy efficiency, understanding the key factors in selecting a lube oil pump is indispensable for industry professionals. As we explore the "Top 5" considerations for selecting the best lube oil pump in 2025, we will delve into performance metrics, efficiency ratings, and innovative features that can significantly impact operational success.

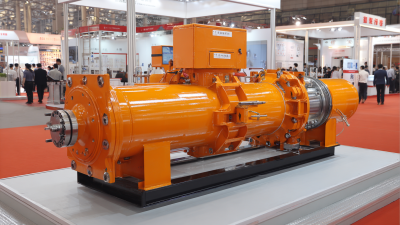

Understanding Lube Oil Pump Types: A Comprehensive Overview for 2025

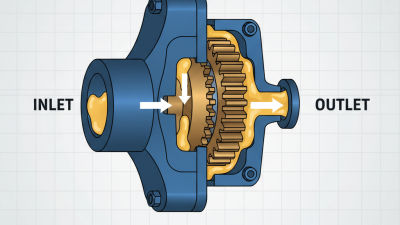

When selecting the best lube oil pump for 2025, understanding the various types available is crucial. Lube oil pumps can be categorized into different types, including gear pumps, diaphragm pumps, and vane pumps. Each type has unique characteristics that make it suitable for specific applications. Gear pumps are known for their reliability and efficiency, making them an ideal choice for high-viscosity oils. Diaphragm pumps, on the other hand, are excellent for handling corrosive fluids, while vane pumps offer adjustable flow rates, which can be beneficial in some industrial settings.

**Tips:** When assessing the types of lube oil pumps, consider the viscosity of the oil you'll be using and the operating conditions of your machinery. Make sure to review the manufacturer’s specifications and look for pumps with a proven track record in your industry.

Moreover, it’s essential to take into account the maintenance requirements and the ease of installation when choosing a lube oil pump. A pump that is easy to maintain can save valuable downtime and reduce long-term operational costs. It's also wise to consult with industry professionals to get insights into the latest technology advancements in pump design that can enhance both performance and efficiency in your applications.

**Tips:** Regular maintenance checks can significantly extend the life of your lube oil pump, so establish a routine that includes inspecting seals and bearings as part of your preventive maintenance program.

Key Performance Indicators: What to Look for in Lube Oil Pumps

When selecting the best lube oil pump, focusing on key performance indicators (KPIs) is essential to ensure optimal functionality and efficiency. One crucial KPI is the pump's flow rate, typically measured in liters per minute (L/min). According to the National Fluid Power Association, ideal pumps for industrial applications often operate at flow rates between 10 to 120 L/min, depending on the specific requirements of machinery. Higher flow rates can enhance lubrication effectiveness, reducing wear and tear on components, which can lead to increased lifespan and reliability.

Another significant KPI is the pump's energy efficiency. The U.S. Department of Energy reports that energy-efficient pumps can reduce operating costs by up to 30%. Evaluating the pump's power consumption in relation to its output is vital, as pumps with a high efficiency rating minimize energy losses, which is not only cost-effective but also environmentally friendly. Additionally, monitoring the noise levels of pumps is important; quieter operations typically indicate better design and manufacturing quality. In this regard, pumps that adhere to ISO 14001 standards for environmental management can help organizations meet regulatory requirements while optimizing operational performance.

Efficiency Metrics: Analyzing Energy Consumption in Oil Pump Operation

When selecting a lube oil pump, efficiency metrics play a crucial role, particularly in relation to energy consumption. According to the latest report from the Hydraulic Institute, energy consumption can account for over 60% of the total operational costs of oil pumps. Therefore, understanding these efficiency metrics is essential for both performance benchmarking and long-term operational savings.

To ensure optimal performance, consider evaluating the pump's power consumption against its flow rate. A high-efficiency pump can achieve a flow rate of about 300 liters per minute with an energy input of just 2 kW, as indicated by the American Pump Manufacturers Association. This not only reduces costs but also minimizes the environmental impact.

**Tips**: When assessing lube oil pumps, always review the manufacturer's efficiency rating and seek pumps with variable speed drives (VSD). Such pumps adjust their performance according to the system's demands, leading to significant savings on energy costs. Additionally, implementing routine maintenance checks can further sustain pump efficiency and prolong equipment lifespan.

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

This chart illustrates the energy consumption of different lube oil pump models, allowing for a comparative analysis on efficiency. Lower energy consumption can signify a better-performing pump.

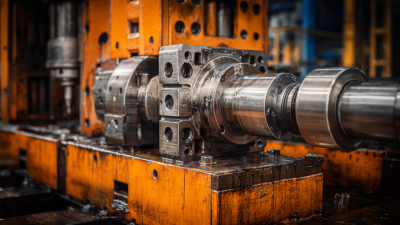

Market Trends: Increasing Demand for High-Performance Lube Oil Pumps

The global market for high-performance lube oil pumps is witnessing a significant surge, driven by increasing demands across various industries such as automotive, manufacturing, and energy. According to a recent report by MarketsandMarkets, the lube oil pump market is projected to reach USD 4.3 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth is largely attributed to the rising need for efficient lubrication systems that optimize machinery performance and minimize downtime.

Key factors influencing this demand include the escalating production of internal combustion engines and the subsequent need for effective lubrication solutions to enhance engine life and performance. Additionally, advancements in pump technologies, such as the integration of IoT for predictive maintenance and monitoring, are making high-performance lube oil pumps more attractive to manufacturers. A study from Grand View Research highlights that enhanced fuel efficiency and stricter environmental regulations are also propelling the adoption of high-performance pumps, as industries seek to improve their operations while meeting sustainability goals. This market trend underscores the critical role that advanced lubrication systems play in ensuring operational efficiency and longevity in equipment performance.

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

| Pump Type | Max Flow Rate (L/min) | Power Requirement (kW) | Efficiency (%) | Typical Applications |

|---|---|---|---|---|

| Gear Pump | 50 | 5 | 85 | Industrial Machinery |

| Vane Pump | 70 | 6 | 90 | Automotive Systems |

| Diaphragm Pump | 30 | 3 | 75 | Chemical Processing |

| Screw Pump | 100 | 8 | 92 | Marine Applications |

| Centrifugal Pump | 80 | 7 | 88 | Power Generation |

Expert Recommendations: Choosing the Right Lube Oil Pump for Your Applications

When selecting the right lube oil pump for your applications, it's essential to consider both performance and efficiency. Different industrial processes demand distinct specifications, so understanding the unique requirements of your system is crucial. Expert recommendations suggest focusing on pump design, compatibility with various oils, and the operating environment. A pump’s ability to maintain a steady flow rate under varying pressures can significantly influence lubrication effectiveness and equipment longevity.

Tips: Always assess the viscosity of the oil you will be using, as it directly impacts pump selection. Choosing a pump that is specifically designed for the viscosity range of your lubricant can enhance performance and reduce wear on both the pump and machinery.

Another important factor is the pump's energy consumption. Opt for models that feature energy-efficient designs to minimize operational costs. Remember, a well-chosen lube oil pump not only improves performance but also contributes to the overall sustainability of your operations. It's worth investing the time to gather insights from experts and conduct a thorough comparison of available options.

Related Posts

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs